We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. Hit the link at the bottom of the post to submit your own question.

Welcome back to the Bikerumor Ask A Stupid Question series. This week we switch to gravel wheel technology, considering the merits of asymmetric and symmetric rim profiles, internal spoke nipples, vibration damping, and how many spokes is too many spokes?

Joining us are the following experts:

- Rik Kusters, co-founder of Scope Cycling

- Ollie Gray, Brand Manager for Road and Gravel at Hunt Bike Wheels

- An as-of-yet-to-be-named representative from Reserve

- Federico Gardin, Brand Manager atFulcrum Wheels

Which kind of rim profile is best for gravel riding, symmetrical or asymmetrical?

Hunt: It depends on a couple of variables, not least the form of gravel riding you do. As we all know, gravel means many things to many riders. For example, the HUNT 42 Limitless Gravel Disc is designed to maximize aerodynamic performance when gravel riding/racing, and this can only be achieved with a symmetric profile rim designed to be as aerodynamically efficient with 700×38/42c gravel tyres.

Asymmetry in profile design is focused on maximising durability, as it achieves an improved bracing angle. The consequence is usually more balanced spoke tension between drive side and non-drive side spokes, resulting in a dependable system for those off-grid adventures.

Scope Cycling: The choice for a symmetrical or asymmetrical rim shape is not related to the underground or environment in which the wheels are used. The main reason to use an asymmetrical rim profile is to balance the tension from the drive and non-drive side spokes.

At Scope we use a 2:1 spoke ratio to balance the spoke tension and therefore we do not need to use an asymmetrical rim shape. A symmetrical rim shape is always preferred by us as it outperforms an asymmetrical rim in terms of aerodynamics. Therefore, we only use asymmetrical rims in the case where we can not apply a 2:1 spoke ratio and when aerodynamics does not play a significant role. For example, in case of our R2.O off-road rear wheel which features 28 spokes.

In general, the rim profile is important when it comes to certain riding characteristics such as comfort and durability which are important for gravel riding. When developing a rim shape at Scope, we perform FEM analysis to determine the level of vibration damping for rims. In the case of off-road rims, we want to reach high scores on vibration damping, resulting in a wider and rounder shape of the rim.

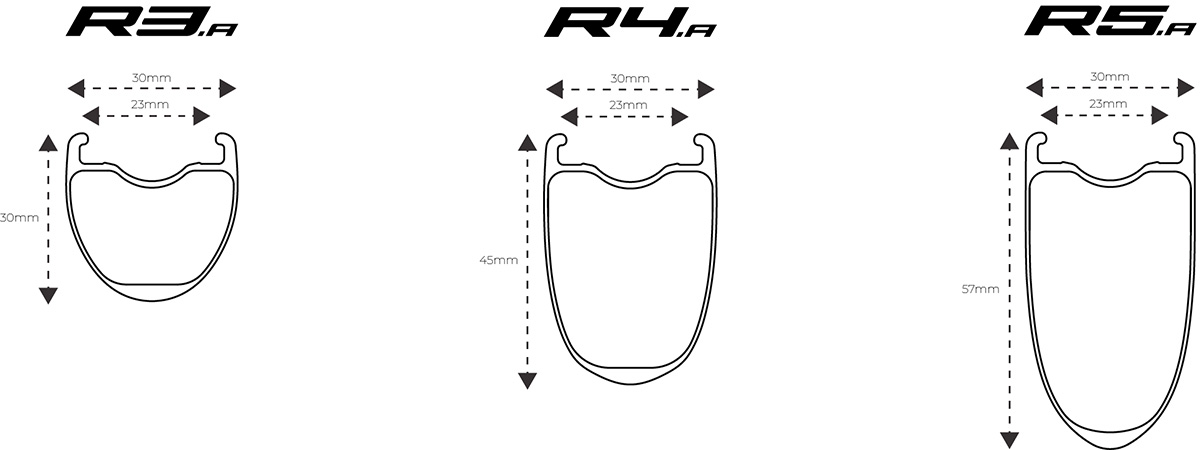

Our range of All Road wheels feature a 30mm wide rim (internal width 23mm) offering both comfort and an excellent aerodynamic performance (low drag combined with a high crosswind stability).

Reserve: Asymmetrical wheels are very effective in balancing spoke tension and length to match the asymmetry of the hubs. This provides for stiffer, stronger and more reliable wheel builds, which are exactly the attributes you are looking for in a gravel wheel. In addition to asymmetry, we (Reserve) also design the profile and material thickness to provide a specific ride quality for the intended category.

Fulcrum Wheels: We at Fulcrum believe that for gravel the asymmetric rim solution is preferable because it guarantees a perfect balance for spoke tension with the possibility to reduce the spoke tensions which, in turn, can help the wheels to better track the ground. This means better control and a more forgiving, more comfortable ride feel.

Do you use internal spoke nipples? Will they work with asymmetric rims?

Hunt: Yes, asymmetrical rims make it more difficult to use internal nipples mainly due to the access from the tyre-bed to the nipple. This is because the hole on the tyre-bed is limited in its size and location in the well of the tyre-bed. Further issues arise for lower profile rims due to the proximity of the internal nipple to the sidewall on the offset side.

It is plausible in cases of a small asymmetric offset or deeper specifically-designed rims to do it; however, this adversely affects ease of use and might not align with the benefits of designing asymmetrically (to the point where we do not design any of our rims or wheels, asymmetric or otherwise, with internal spoke nipples).

Scope Cycling: Internal spoke nipples can be combined with offset spoke hole drilling. At Scope we neither use offset drilling (for the same reason as we do not use asymmetrical rims) and internal nipples because of serviceability.

Reserve: Internal spoke nipples can be used with offset designs, but we don’t recommend internal designs. Rims designed to be built with internal nips will have smaller spoke holes to increase surface of contact with nipples, so all Reserve wheels are built with external nipples, which we have found are easier to build and maintain, provide a better overall wheel structure, and have negligible measured impact on drag.

Fulcrum Wheels: We (only) use external nipples because it makes everything easier for maintenance.

On our carbon and high-end alloy models we use our MoMag patent technology where the nipples, once inserted inside the rim via the valve hole, are “guided” to the point of connection with the spoke by means of the magnet. This simple but ingenious system makes it possible to have wheels/rim beds without holes on the upper bridge to make the wheels tubeless without the use of the annoying tubeless tape.

Are gravel wheels designed to deliver more vibration damping than MTB wheels, given the lower-volume tires and lack of suspension?

Hunt: It’s a difficult one to compare, not least because the performative needs of wheels in gravel and MTB are quite different. MTB wheels are usually very shallow in profile, which is definitely one of the easiest ways to build in vertical compliance, but increasingly gravel riders are looking to aerodynamics as an area to improve their speed, so this isn’t quite as easy.

There are several ways in which we design our gravel wheels to improve vibration damping. Some of these are focused on the rim, whether low profile designs to add compliance, material selection, or layup optimization (in the case of carbon), but of course the other components such as spoke gauge and count.

This is much the same as in any discipline, but it is the understanding of the specific needs of gravel riders over a wide range of use cases that enables us to deliver comfortable wheels without compromising other characteristics.

Scope Cycling: We design our gravel wheels with a similar level of vibration damping as our MTB wheels. Gravel bikes are used in a wide range of tracks, but typically gravel paths are less rough than MTB tracks. Therefore, it makes sense to use wider tires on an MTB and narrower tires on a Gravel bike.

We recommend changing the width of the tire based on the roughness of the tracks. It is important to note that the impact of tire choice and pressure is much higher compared to the rim shape and carbon lay-up when it comes to vibration damping.

Reserve: In general, all Reserve wheels are designed for a specific application. In the case of gravel rims, we know the rider will appreciate vertical compliance and vibration damping, so we design a profile and apply material in a way that will enhance these qualities.

Fulcrum Wheels: No, but simply because during testing and R&D we detected that the average gravel stresses are not comparable to the average MTB ones, even without suspension. We engineer our gravel wheelset to be gravel specific: more comfortable yet stiff, reactive and as reliable as every Fulcrum product.

Gravel bikes cover a plethora of riding conditions, including touring, so why do the wheels have a maximum spoke count of 32 spokes and not 36? Wouldn’t more spokes be better for the rougher terrain and heavier loads?

Hunt: When developing a new HUNT product, we understand there are a wide range of performance and comfort characteristics to balance for the specific use case and we aim to avoid compromise on one for the benefit of another.

Spokes are an area that has come a really long way since touring bikes with 36 spokes were common. With the advancement of technology such as double or triple butted spokes, we can engineer wheelsets with the same durability as the older 36 spoke offerings with single butted spokes, whilst maintaining other characteristics such as stiffness with just 32 spokes. With our product development and extensive rider testing, this enables us to be confident we have the right number of spokes based on the intended usage.

Scope Cycling: Still many people incorrectly assume that the spoke count of a wheel is the most important factor when it comes to the maximum weight a wheel can handle. Although the spoke count does play a role, we must emphasize that other factors play a much more significant role.

A key point in developing a strong wheel is the bracing angle which is mainly determined by the distance between the drive and non-drive side flanges. Therefore, we always push the flanges of our hubs outwards as far as possible. A high bracing angle leads to a high lateral stiffness, making the wheel efficient and providing it with good handling characteristics.

So, to answer the question; yes 32 spokes is sufficient. We do offer All-Road wheels with 21 spokes in the front and 24 spokes in the rear without any weight limit. These wheels can easily handle the high load and rough terrain.

Reserve: The Reserve 22 gravel wheel, and all Reserve road wheels in general, have 24 spokes. We’ve found this provides the best balance between weight and performance. The only application where we have seen a need for a greater spoke count is for bike-packing, where riders are adding 100 pounds or more weight to their bikes.

Fulcrum Wheels: That could be a valid question or query for built/assembled wheel systems; where you’re picking a rim, then a hub, then spokes and trying to make all the parts fit. However, we make complete wheels under the idea of the “all for one”. That’s not just a slogan but, most importantly, a product design philosophy and working method. When it comes to our wheels, actually, we’re able to guarantee the same reliability, and reduce weight, using even a lower amount of spokes (24 in our gravel portfolio).

With the “all for one” design approach, the spoke count number is not everything: we always engineer our products as a complete system, so all the elements, rims, nipples, spokes and hubs, are designed together as a system from the first step in the development process to the built wheel. It means we can be sure we balance all the elements; spoke to rim angles, spoke to hub angle, spoke count, all to obtain the ride feel and performance we consider the best for a certain application.

We make wheels, not components.

Got a question of your own? Click here to use the Ask A Stupid Question form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!