For 2025, Fox has completely redesigned their Factory-level GRIP fork dampers with an all-new valve architecture that makes them simultaneously plusher and more supportive.

With the stated goal of “Pushing Potential Further”, the new GRIP SL, GRIP X, and GRIP X2 offer distinct tuning characteristics for three distinct types of riders. With past generations, they had a fork chassis (32, 34, 36, 38, 40) for every bike category. Now, they have a damper to own every category, too.

Here’s everything you need to know about the next generation of GRIP dampers…

2025 Fox GRIP Dampers are all about Pressure Balancing

The key buzzword at the 2025 GRIP launch was “Pressure Balancing”. It’s a tuning philosophy that, thanks to the use of much more advanced measurement devices they’ve started using inside the fork, allows them to create pressure differentials inside the damper shaft.

I’ve spent hours talking with Bill Brown, Fox’s VP engineering, to understand it, and you can listen to my podcast interview with him for more. But here’s a graphic to help illustrate why pressure balancing matters. It’s also a lot of text (sorry, not sorry), but that’s because it’s a lot to explain.

What’s the TL;DR version?

The new GRIP dampers let you use more compression damping while still being less harsh thanks to new compression damping valves that let the fork react more quickly to high-speed impacts. If you’d like to how they did it, read on…

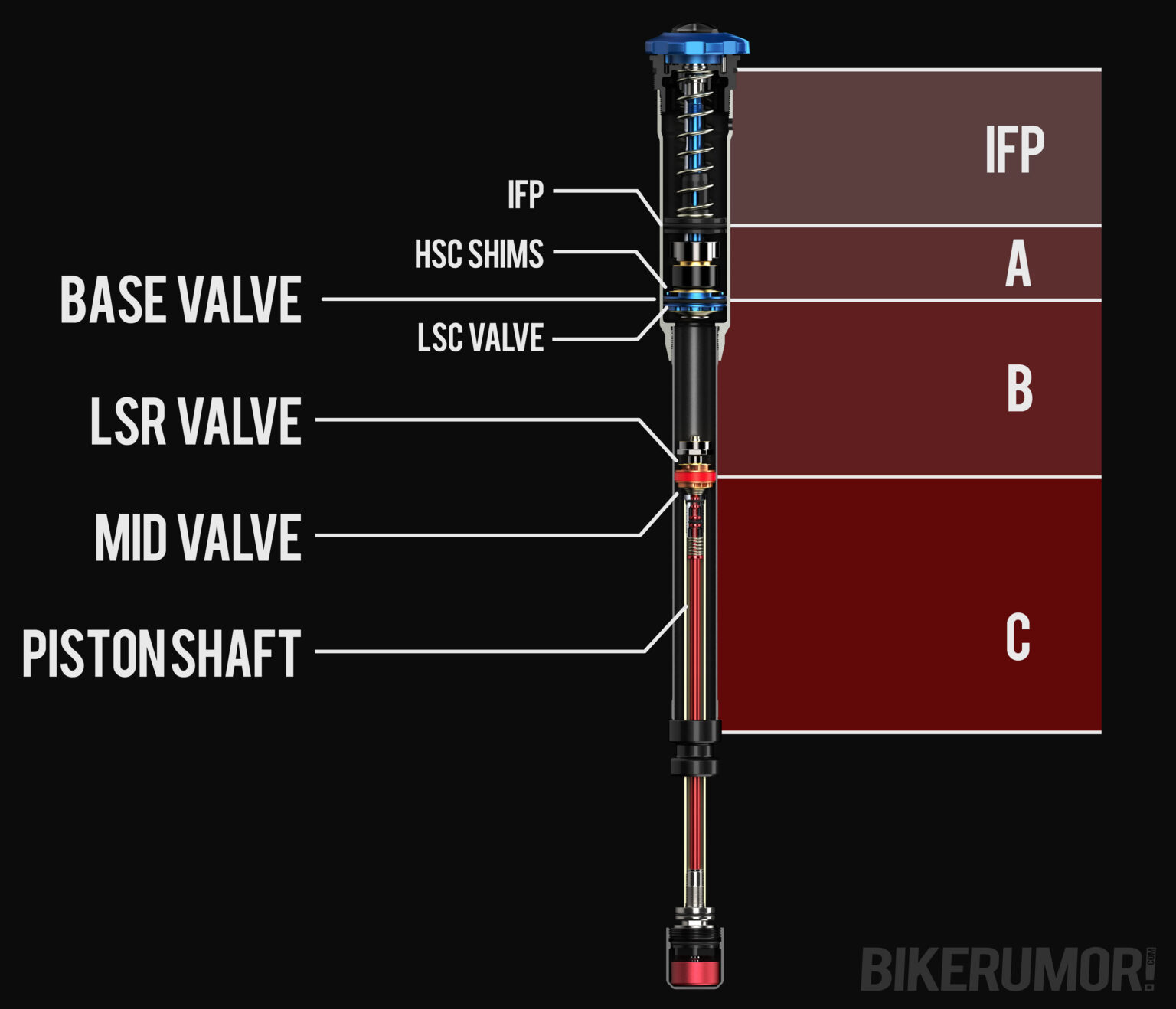

Every modern sealed monotube damper cartridge makes damping at two places – the compression Base Valve, and the Mid Valve. The Base Valve is where the compression damping circuits (shims, ports, valves, etc.) are located and has typically been the only place where compression damping was controlled (for all brands, not just Fox).

While it may look like the Mid Valve is a plunger that pushes oil up through the Base Valve, the reality is that it’s effectively a sieve that lets oil pass through it freely between areas B and C in the graphic above. As the Piston Shaft is pushed into the damper, it displaces oil, and that oil has to go somewhere…and that somewhere is through the Base Valve into area A.

That oil in A then compresses the IFP, which has a coil spring behind it to push the oil back through the Base Valve during rebound (more on the IFP later).

So, because oil mostly* flowed freely through the Mid Valve, the oil pressure in B and C was mostly the same. That meant all of the compression damping had to be handled by the Base Valve’s High (HSC) and Low (LSC) valves.

The problem is, that takes too much time & force.

We’re talking milliseconds here. Fox says a typical complete compression when you hit a big bump takes about 30 milliseconds. Live Valve development taught them that humans can detect something as quickly as 5ms (Not relevant here, but as an FYI, Live Valve can detect and open the valve in 3ms).

So, since it only takes us about 5ms to notice a bump, and about 30ms for a complete HS compression, making the compression circuit react even a few milliseconds faster is the difference between a bump feeling harsh versus controlled.

The key to learning this was developing new pressure sensors that were fast enough to capture what was happening inside these new dampers. Fox is now measuring down to sub 1ms, and based on the new data, they made a few key changes:

- They added a compression damping circuit to the Mid Valve

- They made the Base Valve’s diameter much larger

- They gave the HSC shim stack dramatically more tunability

Let’s break those down:

Mid-Valve compression tuning

The main issue was that because the GRIP 2’s Base Valve was doing all the work, that damper’s HSC circuit had to be strong enough to resist minor impacts. That meant it took a few milliseconds longer for enough pressure to build to activate the HSC, which meant it took a few milliseconds longer for it to start controlling an impact.

From a rider’s perspective, those milliseconds are perceived as “harshness”.

So, Fox added some light compression damping to the Mid Valve, which can react more quickly. Because the system is now reacting more quickly to control an impact, the overall damping can be softer at the beginning, so the fork feels less harsh.

By lightly restricting the flow of oil from area B to area C, they’re changing the pressure differential between the two, hence the term “pressure balancing”. It’s not a huge change, because anything dramatic would start to create a vacuum in C, which would reduce or eliminate the rebound circuit’s ability to function. So, it’s balanced, to create the desired effect without messing up rebound.

Then, as the impact compression forces grow, they start driving the Base Valve’s circuits, but those are now better, too:

Bigger Base Valve = better flow

Note the difference in base valve diameter in the image above (GRIP 2 on the left, GRIP X2 on the right). By using the Mid Valve to handle some of the damping, Fox could use a larger diameter Base Valve with bigger ports and more shim stacks. This extra flow gave them more control over the transition from oil flowing through the orifices (low speed) to pushing open the shims (high speed).

Smoothing the discontinuity in forces between those two is how they maintain smooth traction during that transition so that there’s no sudden difference in how the fork behaves as it transitions between slow and fast compressions.

For the new GRIP X2, that extra space also let them use more and larger diameter shims in the high-speed circuit’s shim stack. The image above shows the minimal shim stack of the GRIP 2 versus the larger X2, and I’ll explain why that matters further down when discussing the X2 damper specifically.

No more FIT4 damper

All three now use their spring-backed IFP, there’s no more FIT4 damper in the lineup. We dive into why in the podcast, check that out, but the short of it is this: Getting rid of the FIT4’s bladder, which needed room to expand to hold oil overflow as the fork compressed, meant a lot more room for the damper itself…which is a big part of how they gained the extra diameter to do all that stuff mentioned above.

The spring-backed IFP design is also simpler and more reliable. It has a bleed port (the little hole on the side of the tube in the image above) that lets any damping oil that gets ingested into the IFP to bleed out and circulate into the lowers rather than get trapped and cause the fork to “pump up”. The damping oil is the same as what’s inside the lower legs, so it’s fine if they mix.

All of this equals more control, less harshness

Since both the Mid Valve and the high-speed circuit can react more quickly, slowing down the fork as soon as it starts to compress, you can add more high-speed compression damping, and yet have a less harsh fork. Basically, you don’t have to run the HSC wide open to have a “plush” fork anymore. Or, as they put it: “Support when you need it. Damp more, harsh less.”

There’s also virtually no lag in the transition from the low speed to the high speed, which some of their top riders were sensitive to. The forks feel more consistent and predictable throughout their travel regardless of whether you’re swooping through a berm, ripping across roots, or both simultaneously.

*NOTE: Technically, Fox’s prior GRIP 2 Mid Valves did play a small role in the fork’s tune; they weren’t completely benign. But for practical purposes, the new GRIP dampers made them an active part of the fork’s compression damping. Oh, and that new sub-1ms testing equipment? Brown says they’re seeing more things at that level that they think they can improve in the future…

2025 Fox GRIP damper options

The new GRIP dampers are category-optimized based on the use case:

- GRIP SL (xc / marathon / downcountry)

- GRIP X (trail / all-mountain)

- GRIP X2 (aggressive trail / enduro / gravity)

For SL, the focus was weight. For X, the focus was giving the typical mountain biker a sweet spot of performance and useful adjustability without bells and whistles they rarely use. For X2, it was about maximizing tunability, both internally and externally, for riders pushing the limits.

Control dials are purpose built for each damper, too, giving you access to only the features you really need for a given use case.

The new dampers are mostly lighter than before, too:

- GRIP SL is 60 grams lighter than FIT4 in 100mm travel.

- GRIP X is 120 grams lighter than GRIP X2 in 160mm travel

- GRIP X2 is only a 20 gram increase over GRIP 2 in 160mm travel

Here’s what you need to know about each damper:

GRIP X2

Coming from the GRIP 2, which was good, their goal was to increase tunability. Having spent years custom tuning the forks for their top pro riders, they wanted to make it easier to do internal custom tuning for the pros, but also add more useful external tuning so every rider can benefit from it. Combined with the new Mid Valve architecture, it delivers “tunability without penalty.”

Basically, they wanted to give the bike a trophy truck feel, where the goal is to keep the tires on the ground while minimizing vibration and negative feedback from reaching the rider. But you need some feedback for a bike, so the rider can sense what the bike is doing and help maintain traction.

The compression base valve is much larger (24mm vs 20mm), and there are more shims. GRIP 2 had 7 shims, the GRIP X2 has 23 shims. That’s more than a 3x improvement in tuning range.

Also has a faster response, so it’s acting on the compression more immediately for a more predictable feel, and they say it makes the top end of the damping curve more useful. Meaning, if you get into a really aggressive trail, you can crank the high-speed compression damping up to handle it, which isn’t something we’d normally do with the old system.

The big functional difference is that the HSC ports are now larger, allowing more oil flow, so they added more shims to resist that flow. Basically, they moved the HSC oil flow management from the ports to the shims, which gives them a lot more tunability. The wave spring (to the right of the shim stack in the image above) loads an intermediate “pivot shim”, which puts more pressure on the center of the shims. The (black) hat that preloads the pivot shim is a tunable item…meaning, it’s a part that they can swap out with different designs to custom tune the fork internally.

Lastly, there’s now better separation between compression and rebound so there’s less cross talk between them. One won’t affect the other.

The GRIP X2 retains the four-way adjustment of external high/low speed compression and high/low speed rebound. It’s available on 36, 38, and 40 series Factory and Performance Elite forks. Some bikes may spec this damper in a 34 chassis, but it’s an OEM-only option.

GRIP X

Fox’s goal for the GRIP X damper was to “Dominate All-Mountain” by offering 4-way adjustable performance in a 3-way damper. Meaning, it’s going to perform like an X2 for most riders, but loses the external high-speed rebound adjustment.

Prior to this, you needed to choose between an endurance, XC-focused damper (FIT4) or a gravity-oriented damper (GRIP 2). Now, the GRIP X is purpose-built for what most of us are riding – trail to all-mountain.

It uses a similarly oversized base valve as the GRIP X2, but has its own tricks tailor-made for riders who climb up trails as much as they bomb down them.

The biggest unique feature is a new “Super Firm” mode combined with a new outer HSC bezel with a small indicator nub.

The center LSC dial acts just like it did before, giving you a huge range of low-speed compression adjustment. But the new HSC knob sweeps 170º and serves multiple purposes. The first ~90º is only pushing a spring down on the shim stack, firming up HSC. After that, it starts to press down on the low-speed compression valve, eventually closing it off completely.

This lets you use a single dial to firm up the fork for climbing, then quickly open it back up, all without affecting the low-speed compression circuit. Meaning, you can leave LSC where you like it, but still have something like a “climbing” mode. The addition of the tiny nub lever provides a visual indication of where it’s at, so you can quickly return to your preferred HSC setting, too, without having to count clicks.

For Rebound, they limited it to LSR, which allowed them to make a smaller, simpler mid-valve (check the comparison photo up above, it’s a lot smaller than GRIP X2!). They also narrowed the adjustment range a bit, so each click will have a more nuanced adjustment.

You’ll find this on the Fox 36, 38, and 40 forks in Factory and Performance Elite trim levels.

GRIP SL

For the SL, the goal was to make the lightest possible damper while also improving performance relative to FIT4. Racers want light weight, the ability to carry more speed with more confidence, and a lockout. The GRIP SL damper provides all three.

A 3-position compression knob has the typical Firm, Medium, and Open modes, but it’s also available with a remote lockout option. The lever provides only low-speed compression damping controls, and the lockout has a blowoff just in case.

The GRIP SL damper is made for travel from 40-130mm travel, for gravel to 34 SC, and all else being equal, this plus a new Kabolt SL axle (it’s butted on the inside to save 12g) makes the 2025 34 Step Cast fork 62g lighter than before.

The Open uses a mix of mid-valve and base-valve (pressure balancing!) for a buttery smooth feel over any terrain. The Medium (“pedal”) position adds more damping into the base valve to give it a bit of a platform. And the now-larger lever on the knob makes it easier than ever to reach down and flick it into the “attack-ready” Firm mode, whether the fork is loaded or now. It has a 140º sweep from open to closed, with solid detents so you don’t have to guess where it’s at.

Available on 32 TC (gravel), 32 SC, and 34 SC forks in Factory and Performance Elite levels.

New GRIP dampers are backward compatible

All of these dampers are backwards compatible with all current chassis, giving you the ability to add these to all of their current forks as far back as 2021-22, depending on model.

The MY25 forks will also have new bushings, which no longer have bleeder channels to circulate oil above and below the bushings. Now, those ports are cast into the lowers, so you can’t retrofit the new bushings into your older fork, but it really doesn’t matter – The new seals do technically have lower contact pressure since there’s more surface area, which means less friction, but even Fox says the difference is minimal. Marginal gains, though…

They also have an eMTB tune, generally with a slightly softer compression tune that’s better for an eMTB’s typically faster climbing speeds.

What about the Performance-level forks?

The prior GRIP 2 damper carries over on the Performance level products, but with updated tune and pressure balancing to achieve some of the same performance improvements. It won’t be Factory level, but it’s better than before.

Do the fork chassis change? Are they travel adjustable?

The uppers and lowers for all forks except the 32 SC carry over unchanged. The 32 gets a complete overhaul, which is covered in a separate post. For the rest, Fox also offers e-bike specific chassis.

Travel options for all chassis are:

- 34 SC – 100-120mm

- 34 – 120-140mm

- 36 – 140-170mm

- 38 – 160-180mm

- 40 – 203mm

Each travel increment requires a distinct air spring, because the piston needs to line up with the transfer port. So, yes, the forks are travel adjustable, but you have to buy a new air spring to change them.

Whoa, whoa, whoa… what’s up with that Gold fork?

That’s a special edition coming out this summer to celebrate Fox’s 50th anniversary. More details will come closer to its release date, but if you want one, talk to your local bike shop now so they’re on it.

First impressions ride review, coming soon.