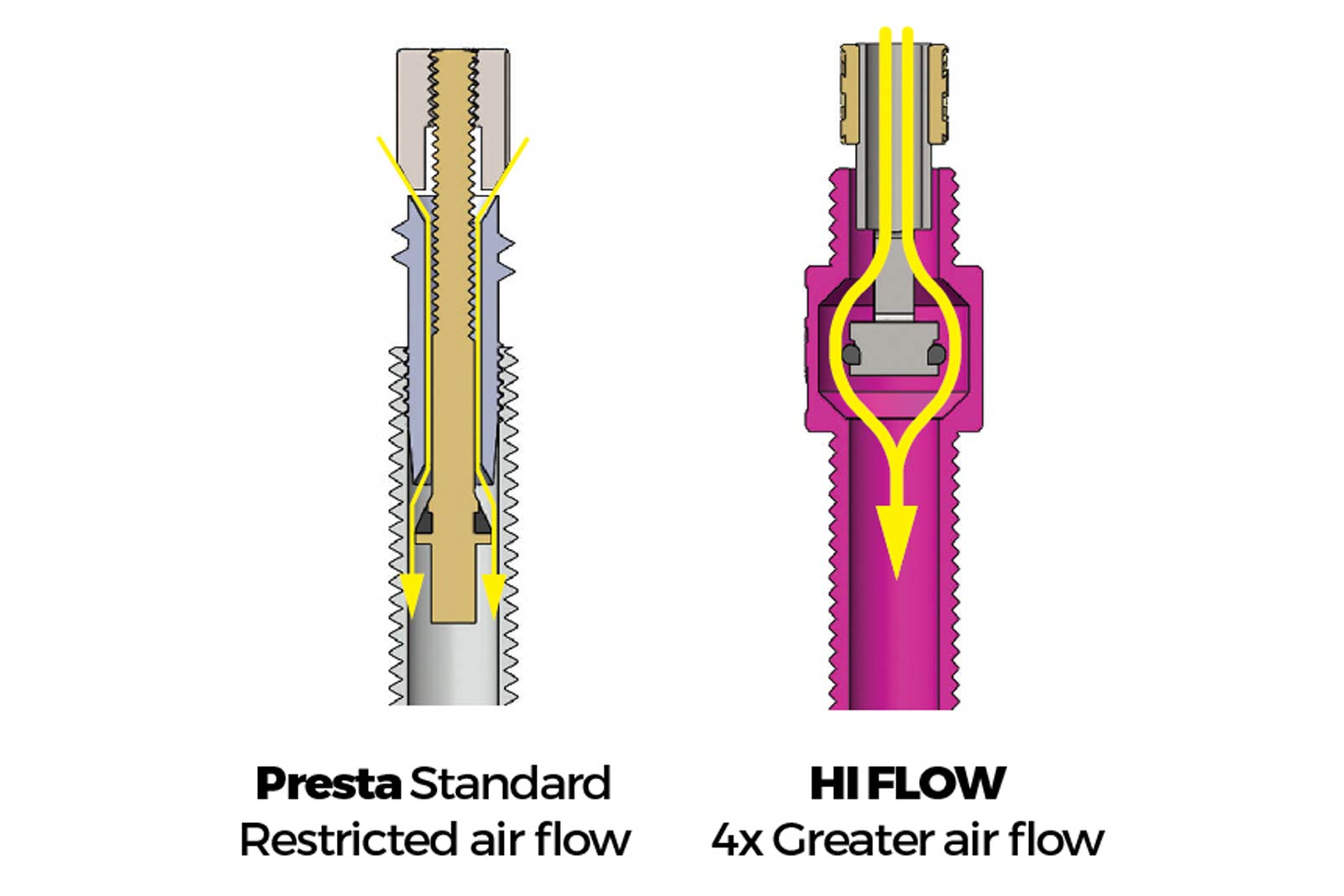

Before we get into it, let’s address the elephant in the room. Reserve recently released the Fillmore Tubeless Valve, a reinvention of the regular Presta Valve, adapted to increase air flow four fold. Not entirely sure how we missed this but, turns out that, several months ago, 76 Projects released their new tubeless valve that also offers 4X times the airflow of Presta. The two designs are very different, however, and it seems to me that 76 Projects’ offering is more compatible with tire inserts. Here’s all you need to know.

76 Projects Hi Flow No Clog Tubeless Valve

The Presta Valve has been serving riders of all kinds of bicycles very well for many, many years (probably since before you were born). With the almost ubiquitous uptake of tubeless systems, particularly in mountain biking, shortcomings of the traditional Presta design have been highlighted. The first of those issues is encountered when seating the tire on the rim. As the rate of airflow permitted through the Presta Valve isn’t all that high, you’ll often find you need to remove the valve core to inflate the tire in a rapid enough fashion that the beads will seat.

Secondly, there’s the Presta Valve’s tendency to clog up with sealant… only last week I had to use pliers to unscrew a Presta Valve clogged up with Slicy Banana Smoothy. My riding pal at the time also made use of them shortly afterwards for the very same reason.

So, how does the 76 Projects Hi Flow No Clog Tubeless Valve circumnavigate these issues?

Like the Presta Valve, the 76 Projects offering runs a removable valve core, but key to this design is the fact that this one is hollow; air and sealant go through the hollow core before passing into the lumen of the valve stem and finally into the tire. It is the volume of the valve core that is responsible for the massive increase in air flow.

Like the Presta Valve, the 76 Projects offering runs a removable valve core, but key to this design is the fact that this one is hollow; air and sealant go through the hollow core before passing into the lumen of the valve stem and finally into the tire. It is the volume of the valve core that is responsible for the massive increase in air flow.

A key part of the design is that wider region near the top of the valve. Here, the external diameter increases to allow the internal diameter to increase. It is at the bottom of this wider area where the valve core seal sits; screwing down the valve core pushes its seal down against the region where the lumen begins to narrow again. Functionally, this presents a notable difference to the design of the Reserve Fillmore Valve, which seals at the very bottom of the valve stem, a feature that will likely make its use with certain tight fitting tire inserts such as CushCore a little problematic.

The higher volume design of the valve is responsible for it’s “No Clog” tagline. We don’t have exact measurements to share, but it’s clear from the following image that the hollow region within the valve core is fairly voluminous. Thus, the valve is said to be compatible with sealant injection systems like Stan’s The Injector. In the event that the valve does clog, the core can be removed for a thorough clean.

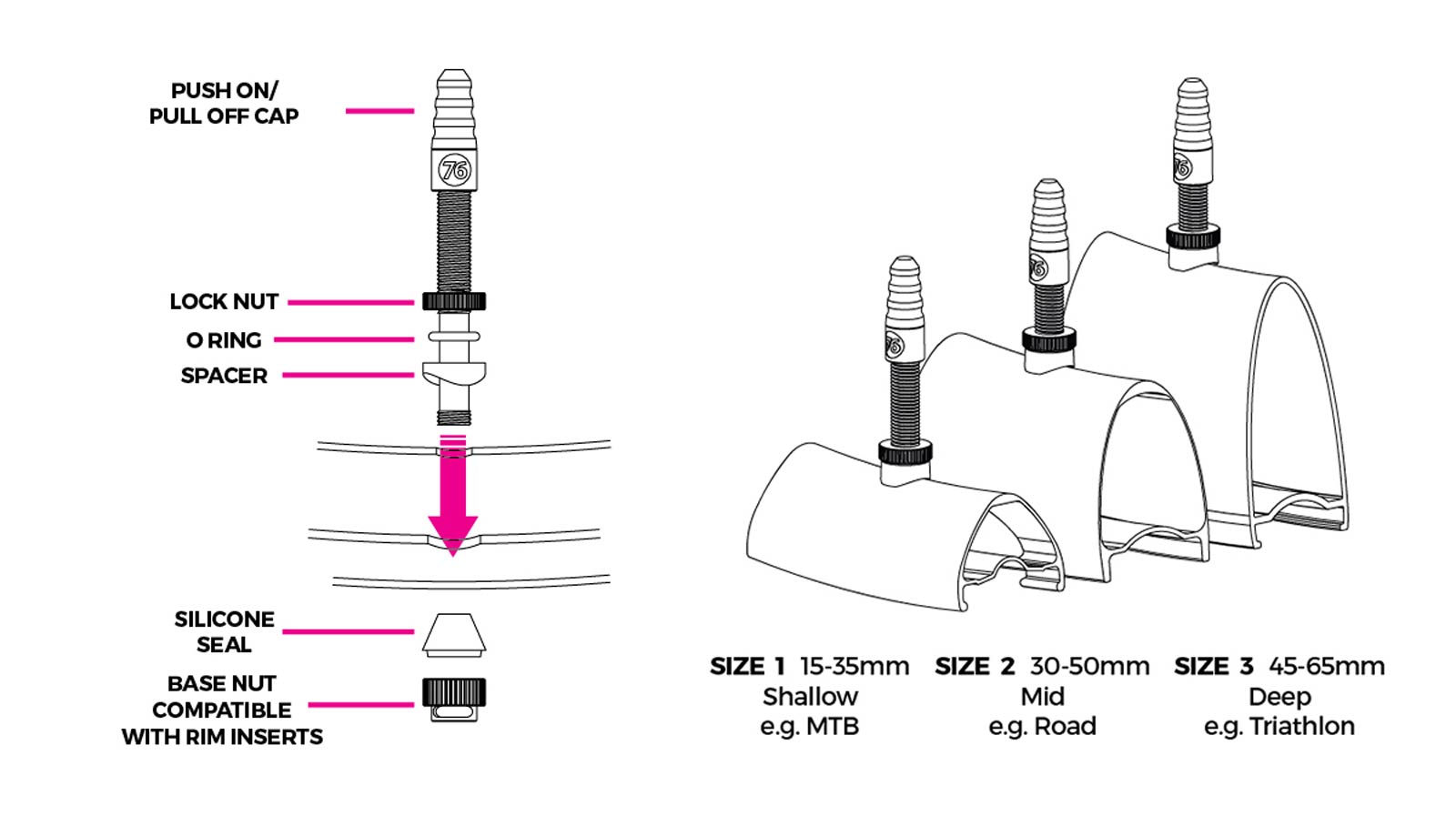

With its larger external diameter, installation requires a few more steps than you’ll be accustomed to. Why? Well, to accommodate the wider stem, the 76 Projects Valve is actually composed of seven individual parts, as opposed to the four parts that comprise the regular Presta Valve.

As you can see in the following image, and in the installation video provided by 76 Projects, a base nut that sits inside the rim seals the valve from underneath, working in concert with the external lock nut that tightens the whole assembly from the outside. Note the bridged portion of the base nut – that should allow these valves to work seamlessly with tire inserts.

The valve is optimised to work with push-on pumps, though 76 Projects do provide an adapter for use with screw-on pumps.

What do you guys think? Is the 76 Projects offering better or worse than Reserve Fillmore? Let us know in the comments.

Pricing & Availability

The 76 Projects Hi Flow No Clog Tubeless Valves are available now, directly from 76 Projects, retailing at £24.50 per pair. Get them in Black or Magenta.