We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. This time we answer your wheelset tech questions across Road, TT, Tri, Gravel, Enduro, and DH! Hit the link at the bottom of the post to submit your own question.

On this week’s Ask A Stupid Question, Industry Nine, HED Cycling, ENVE, and 3T answer your wheel technology questions across almost all cycling disciplines. Topics include disc versus spoked aero wheels for the time trial, enduro versus downhill wheels for DH racing, and aero gravel wheelset technology. Got a question you’d like to ask? Send it in here!

Why are some TT/Tri disc wheels solid (like Enve disc) while some have spokes (like HED Jet). Is one better than another?

HED Cycling: Simply, disc (solid) wheels are faster. But, this isn’t just something ENVE does. Disc wheels happen to be the first wheel HED created. Steve made his first solid disc wheel in a garage back in 1984, and most wheel manufacturers also produce disc wheels.

Why are they faster? It’s all about aerodynamics. That is, they slip through the air with less turbulence and at a lower drag than an open, spoked wheel. On a flat course, a disc wheel can get you 0.5–1.0 kph faster compared to typical spoked wheels, and the advantage can be even greater in some crosswind conditions.

If you want to go faster, then the lower drag of a disc wheel in a lot of cases will be better. But, it always comes down to the type of riding you’re doing.

Disc wheels are heavier than their non-disc counterparts, so if your race is all uphill, then you might want to opt for a lighter non-disc wheel. Emphasis on “might”.

At UCI World’s in 2017, the course ended with a 3.4 km climb averaging 9%. Some riders swapped their TT bikes for climbing bikes at the bottom of the climb, believing that a lighter bike would be faster on the climb, allowing them to overcome any time spent doing a cyclocross style bike change.

Others, like Tom Dumoulin, did not swap, and he was the man who won the race! Primoz Roglic made a bike swap and ended up taking second. Chris Froome didn’t change bikes and got third. As you can see, even on a hilly course, a rider can reach the podium on disc or spoked wheels.

It’s worth noting that disc wheels are not allowed everywhere. They’re not legal for mass start UCI racing and some triathlons do not allow them, notably the Ironman World Championships in Kona. While most of the disc wheels you see will be rear-wheel only, there are also full disc front wheels that are used in indoor track cycling, like the HED VOLO (which just set the Canadian Hour Record and holds the American Hour Record).

An interesting side note, in the 90s HED even made disc wheels for cross country and downhill. On the non-technical courses of the time, they were a fast setup, if not the most durable wheel out there.

For everyday riding, we tend to recommend a spoked wheel, which, when combined with a deeper carbon section, still offers great aerodynamic performance while giving the rider greater handling and maneuverability. But when it comes to racing against the clock, in most cases, a solid disc wheel is going to be a major advantage.

Enve: We believe so… however, there are pros and cons to each. If you use spokes and bond skins for the sidewalls, then you can still true the wheel, but in order to keep the weight in an acceptable range, the sidewalls become very thin and are easily damaged.

Also, these designs usually compromise aerodynamics for ease of manufacturing. For us, we chose a solid design for durability, weight, aerodynamics, and a no-tape-required tubeless design.

Why do downhill racers choose rims that are rated for Enduro, when there are DH-rated rims?

Industry Nine: There are several reasons a downhill racer might choose an Enduro rim vs. a DH rim:

- Weight – Typically an Enduro rim will be 50-75 grams lighter than a Downhill rated rim. Even though DH racing is by nature a gravity-based event, a lighter bike will be easier to maneuver and will accelerate faster in the pedaling sections of a course, which can provide a small advantage during a race run.

The trade-off is that an Enduro rim isn’t typically designed to hold up to the demands of full-blown DH racing and will be more susceptible to damage from impacts. For a pro-level rider with a full-time team mechanic and sponsorship support, having wheels rebuilt multiple times throughout the season or even a weekend of racing may not be a big deal.

However, for your average racer (or rider) on a DH bike we recommend sticking with a DH-rated rim/wheel as it will be significantly more durable for its intended application.

- Rim width – While most riders and racers have moved to rims in the 30mm inner width range for DH use, there are still some pros who prefer narrower internal width rims. In some cases, these rims are not available in a DH-rated spec, so a rider may choose an Enduro spec rim that is available with a narrower inner width.

- Tire protection – In some cases, a rider may choose a lighter aluminum rim, so that if they have a major impact that bottomed the tire on the rim, the rim would dent or deform rather than pinch flatting the tire casing or tube (although most DH racers are on tubeless now). This has become less of a reason recently as many riders are opting for tire inserts in concert with tubeless DH tires, which help prevent pinch flats.

Can a 20mm x 110mm thru-axle wheel be adapted to fit a 12mm thru-axle fork? And if not, why can’t the two items below be used in unison to accomplish this? I’m seeing a few slide-in caps for making 20mm hubs fit 15mm forks. Plus, there are other sleeve-like adapters for making 15mm fit 12mm. Am I whistling in the dark here?

Industry Nine: This one doesn’t have a straightforward answer. There are two 20mm x 110mm front hub standards. The original ISO spec is typically based on the same hubshell and flange width use on a 100mm hub with end-caps that are 5mm longer on each side to generate the 110mm length.

The newer 20mm x 110mm “Boost” standard typically uses the same hub shell/flange width as a 15mm x 110mm hub but with the larger end-cap/axle interface. In our case, we offer front hubs in both of these specifications for 6-bolt rotors. We also offer 12mm end-caps that fit these hubs.

In the case of the 20mm x 110mm ISO hub, it will yield a 12mm x 100mm front hub specification, since the end-caps are 5mm shorter. In the case of the 20mm x 110mm Boost hub it will yield a 12mm x 110mm front hub (which is being used on some of the newer road and gravel e-bikes, but is still relatively uncommon.)

We cannot speak for other manufacturers, but we do not recommend the use of any non-factory parts to modify our hubs. Additionally, each of the end-caps features a different designated OD (outer diameter) per the published industry standards in order to interface properly with the inset dropouts most forks employ.

Using a sleeve to reduce the ID of the hub axle would not allow a proper interface with most forks on the market as the OD of the endcap would be too large to fit the inset fork dropouts.

I would love to ask 3T about their new 40mm wide discus wheels. In a previous Ask A Stupid Question, I asked ENVE about the rule of 1.05 in regards to gravel and if we would be seeing 40mm wide wheels anytime soon. ENVE said that they don’t think there would be anything like that in the near future and then 3T unveiled just that! My questions are as follows:

1. How do your wheels protect against impacts especially when the wall thickness starts to get paper thin? Bearing in mind that during a gravel race you have big, sharp rocks flying everywhere.

2. How will wheel designers tackle the inner widths of rims? A 25mm inner width on a 40mm wide rim might have some odd geometry and flow characteristics. But, a 35mm inner width may be too wide?

3T: Our top priority is durability; the whole Discus range is built on it. The first layer of defense is the tire, which greatly reduces impact. In fact, due to the smaller tire and the sharp edges of potholes and curbs, a wheel with a road tire riding on paved roads sees higher impacts than a gravel wheel with a gravel tire on gravel roads.

The second part is the hooked rim shape rather than hookless. Although more complicated and expensive to produce, it helps not only in gripping the tire but also in strengthening the rim.

With regards to impacts from loose objects (rocks, branches, etc.), our sidewalls are actually not paper-thin; they are reinforced in the right spots. We prefer the trade-off of a little extra weight and a lot more toughness. Of course, a low weight is sexy and an easy feature to compare wheels with while durability is hard to assess until you own the wheels. In the long run, durability wins.

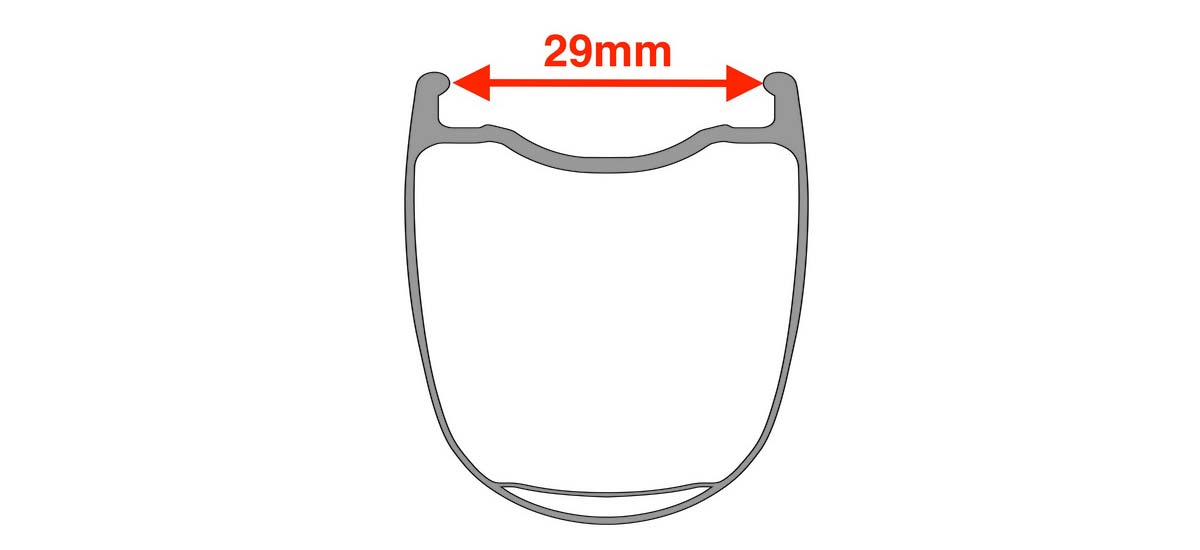

In answer to your second question…. indeed, this is tough in the case of an aero rim. For a non-aero rim, it doesn’t really matter as the outer width is irrelevant. So you pick the inner width and design around that, letting the outer width land wherever it may.

For an aero rim such as the Discus 45|32 and Discus 45|40, we have both the outer width (based on aerodynamics in combination with the tires of choice) and the inner width (based on the dynamics and fit of the tires or choice) fixed, which then also means the flange width (with or without hook) is fixed.

The 45|40 is about as far as we can take that, with a 40mm outer and a 29mm inner. You can add some bulge to the shape so that the width at the tip of the flanges is a bit less than 40mm, but you can’t curve it in too far or you start to lose the aerodynamic performance.

In our particular case, we found that using a shape that is a little worse for the front 180 degrees of the wheel but a bit better for the rear 180 degrees (the Nose Tail design) netted out the same aerodynamically but increased the curve. Thus, the delta between inner and outer width was reduced more than with a traditional aero rim.

Enve: It’s cool to see other companies working on answering the same questions we have. Since our SES AR launch in 2016, ENVE has been carrying the high-volume aero road wheel torch. As more riders have realized the aero and ride quality benefits that accompany these design concepts, other wheel companies have followed with wider aero wheels.

Naturally, gravel wheel design comes into play. With wheel design, it comes down to priorities and the trade-offs you’re willing to make. To make aero work for gravel, you need to make the rim much wider and deeper (we have built and tested designs like this), so weight is going to go up.

If aero is the priority, then the weight gains may be acceptable. Your question about durability is valid as well. If a wheel must be wider, and deeper, you now have to make decisions about durability. Do you take material out of the rim to reduce weight and improve the ride, or do you keep the material in the name of durability and accept that the weight and ride quality will suffer?

These are some basic trade-offs we as designers must consider. For most who are choosing a wheel, it comes down to their priorities and needs based on how, what, and where they are riding.

Is it possible to fit a 132mm hub in a 130mm carbon frame drop-out?

Industry Nine: I assume this question is referring to installing a commuter style 132mm internal geared hub on a traditional 130mm QR road frame. Assuming the 132mm hub uses a 10mm axle (typically these hubs are bolt-on) you could likely spread the frame enough to install the hub. However, this would almost certainly void your frame warranty and I’m sure most manufacturers would recommend against this.

Thank you very much to Jacob McGahey of Industry Nine, Gerard Vroomen of 3T, Jake Pantone of ENVE, and Andy Tetmeyer of HED Cycling for contributing to this week’s Ask A Stupid Question.

Got a question of your own? Click here to use the AASQ form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!

Disclosure: Some of these links are affiliate links that may earn a small commission for Bikerumor if you click on them and buy something. This helps support our work here without costing you anything extra. You can learn more about how we make money here. Thanks!