What tire profile is best for cornering, and how do brands test grip on MTB tires?

Last week, the World’s top mountain bike tire manufacturers joined us to answer your questions on how wheel size and tire width affect cornering grip. This week, the same experts are back, going deeper into the subtleties of MTB tires that help us go around corners. Thank you very much to Schwalbe, Vittoria, Continental, Maxxis, WTB and Michelin for the detailed explanations!

People refer to “rounded” and “squared” tire profiles a lot in review articles. My local trails are very natural in character… there are no berms to speak of. The corners are flat with little to no support. Is one of these tire profiles objectively better for riding flat corners than the other? Or, does it simply come down to personal preference?

Schwalbe: There is always a tangential surface in contact during cornering, but the higher the air pressure, the more likely it is the contact patch (in terms of length/width) will shift depending on whether the tire profile is rounded or squared. That may result in better cornering or better braking/forward traction.

At the lower pressures we use for mountain biking, there won’t be that much difference in terms of length/width of the contact patch. The difference in a rounded/squared profile will more likely result in a different feeling so that it comes down to personal preference.

Rounded profiles will feel more agile. You’ll need to lean the bike more as you corner to get the side knobs to grip the ground and vise versa for the squared profile. Please note that the wider the internal rim width the more squared a tire will get.

We at Schwalbe always try to find a sweet spot in between both extremes, however as long as you run the correct tire pressure every tire will have a more or less square contact patch under load.

What is also important for ride feeling is how the part of the tread pattern between the center area and the side knobs appears. As you lean the bike, a tire with designative intermediate knobs will make the bike more predictable because the knobs are distributed uniformly. Some people like that feeling especially on hard ground. Others like the feeling of tipping over onto the side (knobs) with a distinctive “channel”.

Vittoria: In simple terms, a round profile will provide an even dispersion of tread on a given surface, as the tread is always tangent to the ground. At the other end of the spectrum, a squarer profile will force the side knobs into the terrain, providing more initial cornering bite.

If the tire is too round, there will typically not be a firm bite in mixed-surface cornering. If the tire is too square, then the tire will likely wash out at the cornering limit, as the rider leans past the edge of the profile.

For the rider that asked the question, I would suggest a mixed terrain tire with a neutral profile, and a pronounced side channel between the center and side lugs of the tread. A Vittoria Mazza is a good example, as the profile is more aggressive (square) than an XC tire but less square than a mud spike, while still offering a balanced amount of spacing.

Continental: When you are riding berms, the surface is angled to the wheel and tire. For this reason, parts of the center studs are also engaged and the application of force is different compared to “flat cornering.” This why in berm cornering more speed can be generated.

In “flat cornering” the angle at which the tire is positioned to the ground is much steeper, so it is mainly the outer studs that are in contact with the surface. For this reason, tires with pronounced and well-supported outer studs are particularly suitable for flat cornering, because they can better grab into the surface.

In addition, the transition from the central stud area to the side stud area should be designed harmoniously so that the transition to the outer studs works smoothly.

Maxxis: In general, a rounded profile tire has better steering stability during corning due to the smoother contact footprint change from straight-to-cornering transition. A “squared” profile offers better straight away stability due to larger contact footprint, but the transition might not feel as smooth from straight to cornering.

This comes down to the type of corners and personal riding style; in your case a square profile would likely work better.

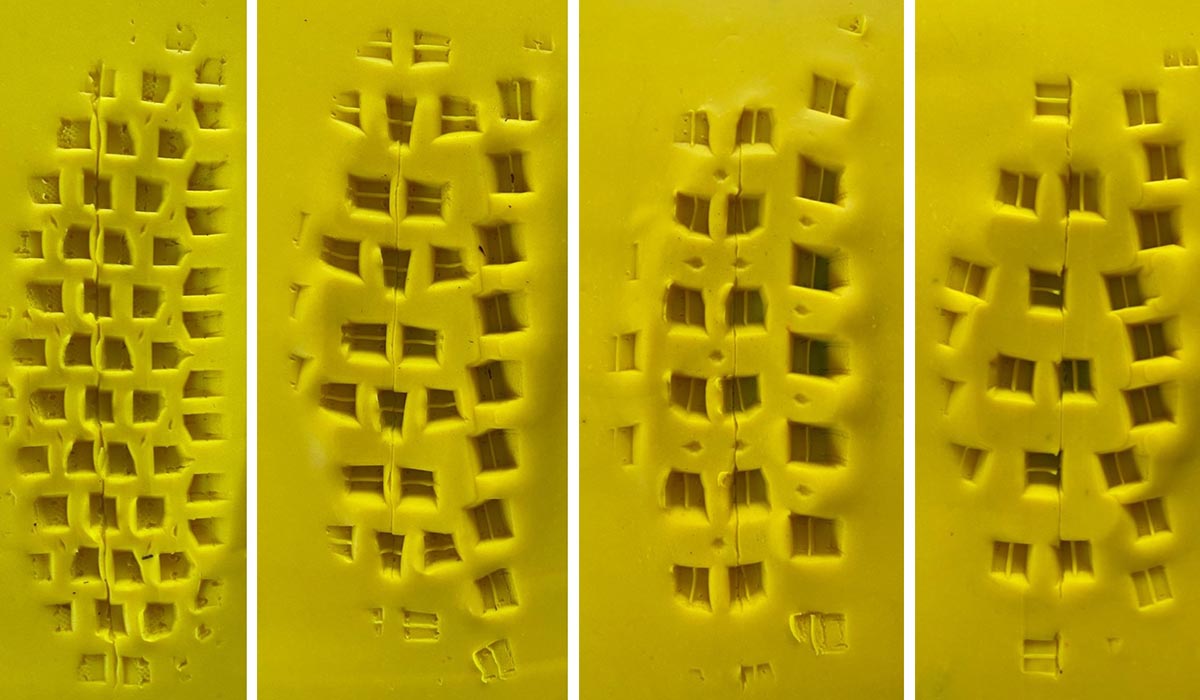

WTB: This is a great question and I think if we go back to the dough (featured in last week’s AASQ) it’ll be a little easier to explain. If we’re assuming that all of the tires in question had the same width and volume, then the bulk of the tire’s profile would be shaped by the tread design – particularly the side knobs.

As the side knobs get bigger, they’ll create a flatter profile. As they get smaller, the profile will be more rounded. When tires have a flatter profile, it means you don’t have to lean the bike over very far before the side knobs start biting into the dirt. Big side knobs mean big cornering traction.

When tires have a more rounded profile, you’ll generally get consistent contact with the ground regardless of the angle you’re leaning at. This doesn’t mean consistent grip though because the more you lean over, the more the tire wants to slide out and the smaller knobs just won’t have the same bite as their larger counterparts.

Above you’ll see imprints from a range of WTB tires. Each tire was pressed into the dough, then leaned over to 45 degrees. As you move from left to right, the profiles get flatter, and you can clearly see how this changes the footprint left by each tire. The flatter the profile, the bigger the side knobs, the more bite as you lean over.

So, back to the original question: It’s actually quite a tricky one to answer because there are numerous factors that influence which tire you should choose. I would actually place tire profile more in the preference category.

As a rule of thumb, I’d prefer a slightly rounder profile on hard pack or “loose-over-hard” terrain to maximize contact, and a flatter profile when the ground is softer to maximize bite.

Michelin: Based on my experience with riders in my MTB career, “rounded” and “squared” tire profiles are a matter of personal preference. Some Michelin riders prefer a stable, more squared tire, while others prefer a more reactive, rounded tire.

Enduro riders prefer more natural trails and a squared profile for stability, while DH riders prefer rounded tires for their reactivity and ease of balancing from left to right. For example, Adrien Dailly prefers the Michelin Wild Enduro tires because they are more stable and predictable, while Sam Hill prefers the Michelin DH22 tires for nimble handling.

When you are on flat corners, the predictability of losing grip is different between both squared and rounded profile tires. When you are at the limit of the grip on flat corners, the squared tires will be less predictable and provide less feedback for loss of grip compared to rounded profile tires.

How do tire makers test cornering grip? Do they just give a bunch of protos to their pro riders or do they have some kind of objective mechanical way of testing grip in house?

Schwalbe: We have no laboratory test for cornering grip. It is almost impossible to test cornering grip in lab conditions and apply any findings to the real world. In mountain biking, there are so many different conditions and surfaces that field tests are the most appropriate.

We test our tires with both pro riders and hobby riders to get a holistic impression. We usually do blind tests so that the riders don’t know what’s new or different. Furthermore our product management team at Schwalbe is really addicted to cycling. We test the tires ourselves at our local trails or go to special spots. This is very revealing because we change wheels in group rides regularly and compare tires one to one.

Vittoria: At Vittoria, we have a dedicated testing facility that simulates various surface conditions, as well as weather conditions, across extreme temperature ranges.

Once the tire is proven in the lab, it is field tested by a large roster of athletes at all levels, from the World Cup and Grand Tours, to local club teams. No Vittoria tire is launched without both data sets, to validate the goal of the project.

By the time we launch a new tire, it has already proven itself in competition. For example, the Vittoria Barzo won the UCI World Championships in 2015, the year it was launched.

Continental: At Continental, we evaluate cornering grip using two methods. Method number one is the lab test, where we measure the grip of a compound in combination with a tread pattern on machines to evaluate the force of friction that the tire generates on a special textured surface in different conditions.

This gives us the opportunity to evaluate the grip based on measured results and numbers – but it often doesn’t tell the whole truth. A major part is the outdoor testing. Here we evaluate the tire’s performance using athletes and ambassadors all over the world in as many conditions and terrains as possible. Getting a lot of feedback can then help us design the tire to perform best for its intended surface, condition and riding usage.

Maxxis: There are several things to consider when an engineer designs a tire for cornering grip. Computer simulation can help check the footprint shape and contact pressure distribution at different lean angles.

Some lab equipment can also measure the lateral force at different lean angles. The lateral force is well related to the cornering grip. However, short and long term field tests with our athletes are always necessary to confirm the cornering performance due to the real world trail/road conditions.

WTB: There are many variables that are constantly changing as you ride down a trail. Therefore, it’s difficult to determine and assign an overall grip value for any tire. We certainly measure the durometer (softness) and hysteresis (rebound) of our compounds, which provides quantitative values for how much traction a certain compound will provide in different conditions, temperatures, etc.

However, none of that replaces real-world testing. It merely supplements it. We believe every compound, casing, puncture protection and overall tire requires extensive real-world testing to really determine how a tire performs.

All WTB products are subjected to extensive periods of testing before we can be certain that we’ve created the best product possible. We make sure our tires are tested across all types of terrain, in all weather conditions, and by a wide range of riders too. The pros are certainly a crucial part of that process and we’ve had numerous prototype products on EWS bikes over the years without anybody knowing.

However, our test roster is not limited solely to pros because it’s not just pros that’ll use them. We make sure to cover all angles when it comes to testing so that when we finally release the product, we can be confident it’ll perform as it should. If our testing duped us and we’re not happy with the production tire…we’ll even update it down the line because if we’re going to sell a product with the WTB name on it, we want to make sure it’s the best available.

Michelin: Michelin has the unique ability to utilize various chemists and engineers to develop specific rubber compounds that attribute to a wide range of product applications. Michelin follows special test methods to evaluate cornering grip and comparison of consistency.

In addition to objective testing of a rubber compound’s grip, test riders provide subjective feedback to define the final product. Riders using prototype tires will replicate their test runs to compare traction at the same speed in the same corner, or to increase the speed at the limit of traction for both solutions.

If a rider is increasing speed with all the same settings on their bike, traction has increased resulting in faster cornering. When testing cornering, the feeling of losing grip is also important, and it’s valuable for riders to understand where they are compared to the maximum limit of traction.

- James Heaton, European PR Guru at WTB

- Alexander Hänke, Product Manager at Continental Bicycle Tires

- Robert Mennen, Product manager at Schwalbe

- Aaron Chamberlain of Maxxis, with input from their engineering teams in the US and Taiwan

- Vincent Ledieu, Michelin bicycle business segment manager and race program leader

- Ken Avery, Senior Vice President of Product Development at Vittoria Tires

Got a question of your own? Click here to use the AASQ form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!