While jokingly aimed at helping bike shops avoid those extended “test rides” that pull mechanics out of the service bay for too long, the Bonas Labs Disc-O-Matic’s real purpose is to quickly and properly bed in disc brakes before a new bike is sent out to shred.

Founder Jonas Mikolayunas says that, too often, bikes are assembled and then turned over to the rider without having the brakes fully bedded and burnished, if at all. The result are underperforming brakes, especially when the rider doesn’t know how to (or even know that they should) spend a few minutes to bed in new pads and rotors.

“The goal of the bedding & burnishing process,” according to Mikolayunas, “is to create a tribolfilm on the pad and rotor surfaces which, unfortunately, can only be detected with expensive laboratory spectroscopy equipment.”

In laymen’s terms, that means embedding pad material into the rotor’s surface to maximize surface contact area, then heat it until it creates a film to maximize friction during braking, and there’s an art and science to the process. Too much speed or pressure can do a poor job of transferring enough material, or prematurely glaze the pads slightly and diminish braking power. Geek out on the process with their Explainer article.

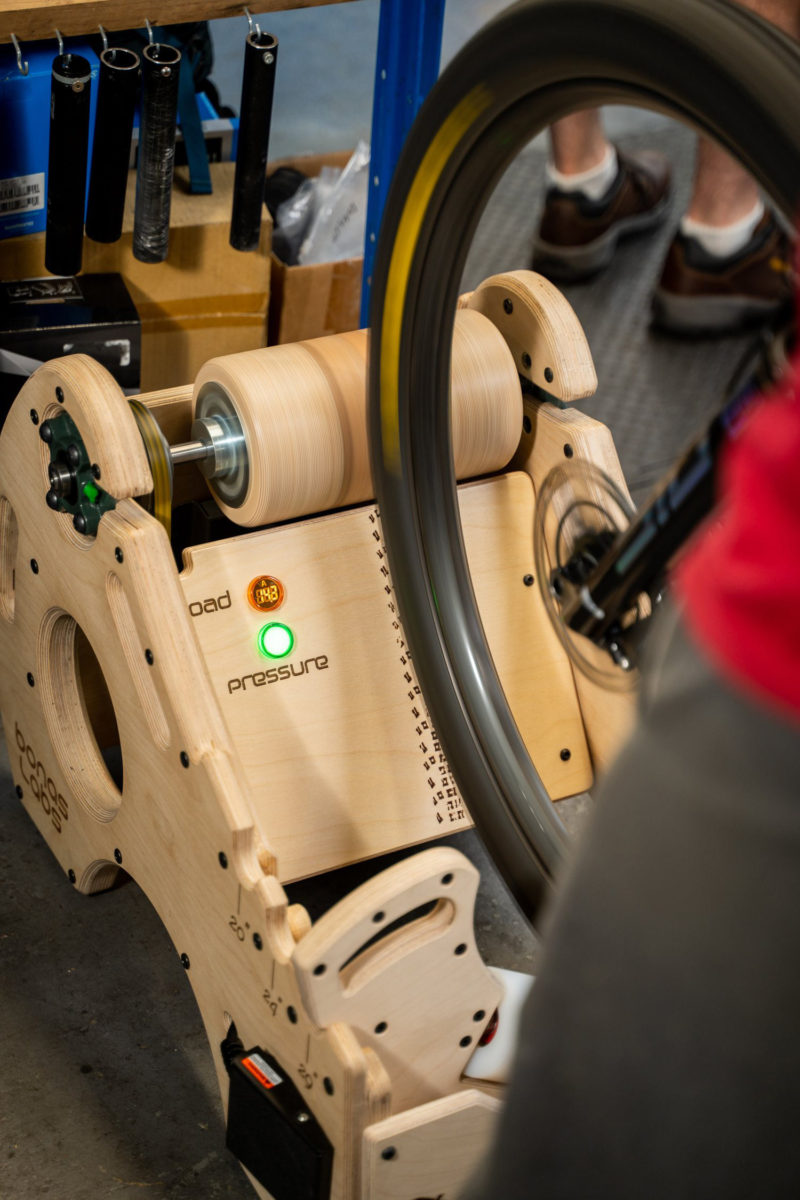

Mikolayunas: “While the final test for the tribofilm presence still relies on the mechanic’s experience and touch to feel for the “before and after” bedding comparison, we’ve given them a consistent platform upon which to operate. The amp load display lets the user know how hard they’re working the motor and the green “pressure” light defines the boundary between the “Bedding” and “Burnishing ” stages. At lower amps the green light is OFF and the user can lightly transfer pad material to the rotor without heating the system up too much. Once that is complete then the user can apply more pressure in short bursts to increase the heat and change the chemical composition of the mixed materials into a triboflim. Both wheels can be bedded and burnished in three minutes.”

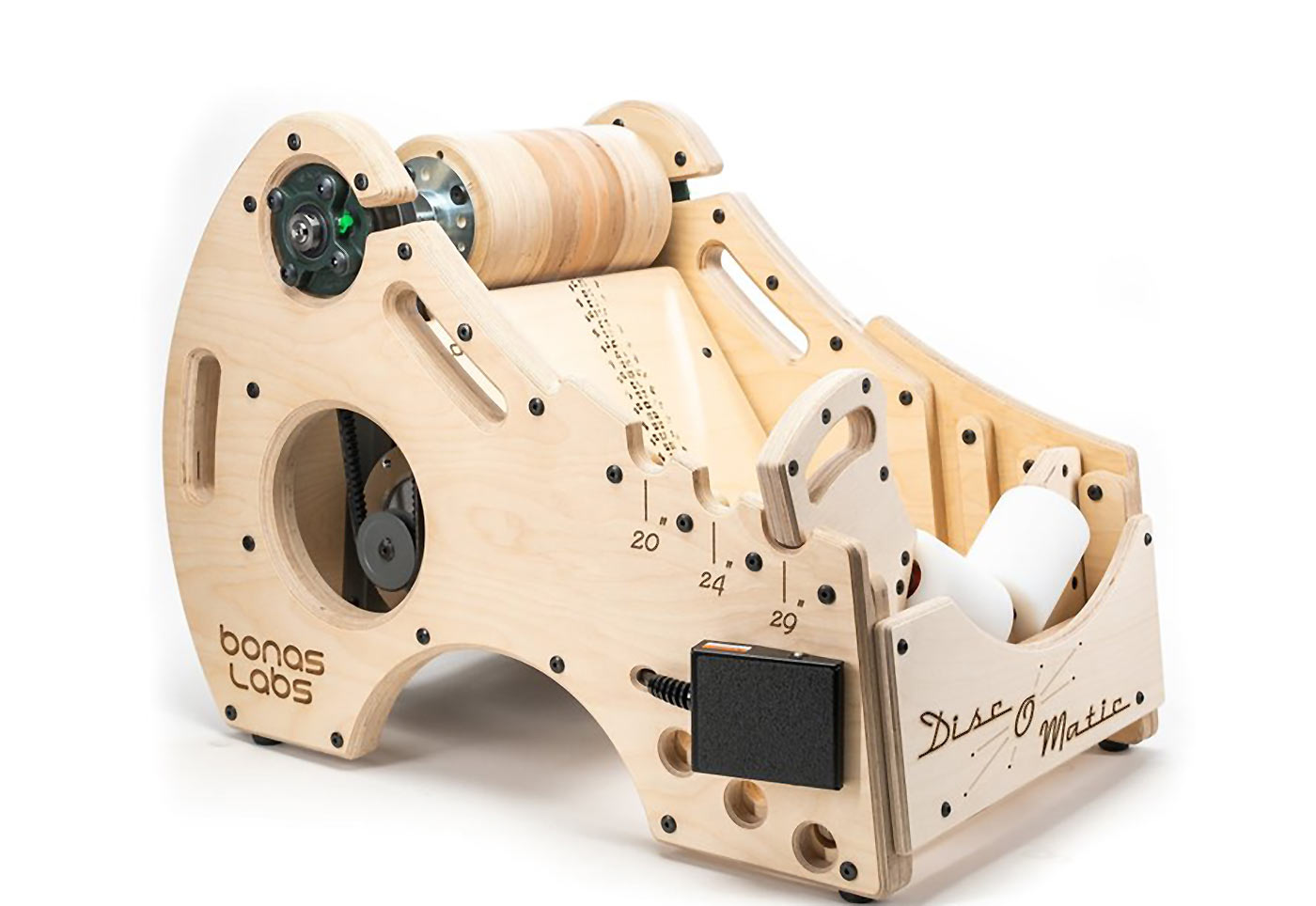

The Disc-O-Matic can bed and burnish both wheels in about three minutes, much quicker (and, likely, safer) than doing it in the parking lot outside the shop, with more consistent (and not weather dependent) results.

The production version shown here currently retails for $3,495 and is aimed at high-volume shops (they have a labor-versus-this-device cost comparison on their website), but say they are trying to bring the price down.

It’s made to industrial equipment standards, yet is easy to assemble, service, and repair. And it’s built as sustainably as possible thanks to the use of a Baltic Birch frame and a hardwood drum for the tires to roll on. A Brushless motor lasts longer, and a kick-panel switch quickly adjusts speed/on/off while you keep both hands on the bike.