Brakco’s Carbon Rotors aren’t the first carbon fiber brake rotors we’ve seen, but they do look like something that could actually work.

The carbon braking surface is attached to an aluminum carrier with stainless steel or aluminum bolts…they had both on display. I got the sense they’re still finalizing the design a bit, but they admit they’re still working on the companion brake pads.

Specifically, they’re developing organic, non-metallic brake pads that can heat up quickly enough – carbon fiber rotors are great for high heat situations like extended steep descending. But they need heat to work well. Brakco’s rep also said those pads will likelywear out very quickly, but that braking performance will be worth it.

The rotors are light, around 65g, compared to 117g for standard steel rotors. Price is TBD until they sort out the brake pads. Two different thicknesses could be offered, too.

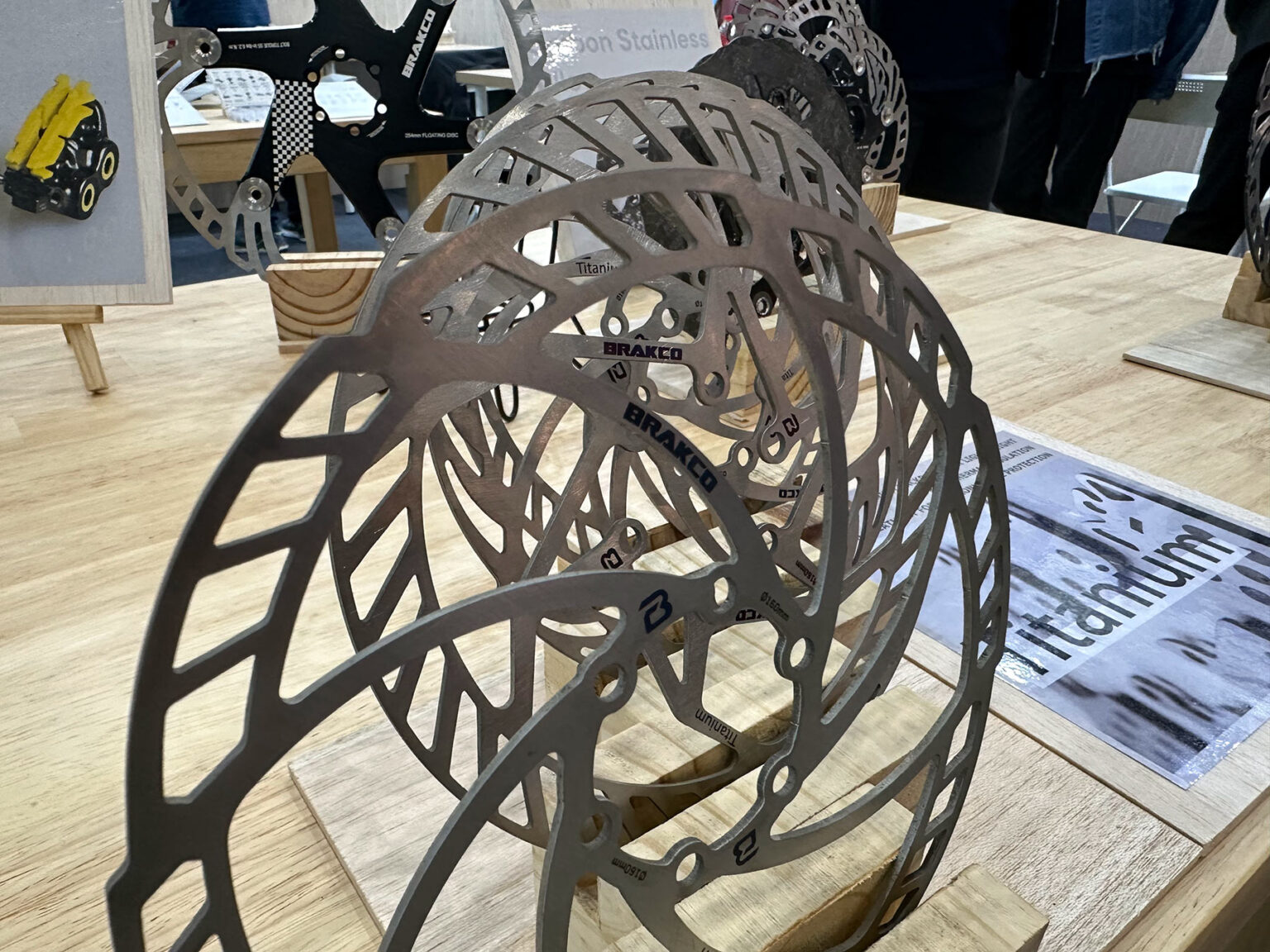

Meanwhile, they also make titanium brake rotors that come in at just 60g for 160mm.

They’re available in several designs, mostly just for looks between them.

New brake pads with titanium backplates transfer less heat into the piston. They’re available with an oil-slick ano or bare, and the un-coated bare ones are more eco-friendly (or you can get them anodized if you don’t care). They’re about 10% lighter than standard brake pads.

Carbon backplate transfers less heat, but they say titanium still works better overall.

Last up is this replaceable cooling fin concept. You can replace the brake pad and reuse the cooling fins, helping keep perfectly good material out of the landfill.