The upcoming Bridge Bike Works Surveyor road bike will be the first model from the upstart brand, and it’s riding high on its North American manufacturing story.

Built from the ground up in Toronto, Canada, Bridge’s all-new factory will produce the frame and fork in house. And, they’ve assembled an all-star team with composites and designers and engineers from brands like Cervelo, Lotus, and more.

We have a podcast interview coming up this week that tells their whole story, so for now we’ll share these pre-launch renderings and early details.

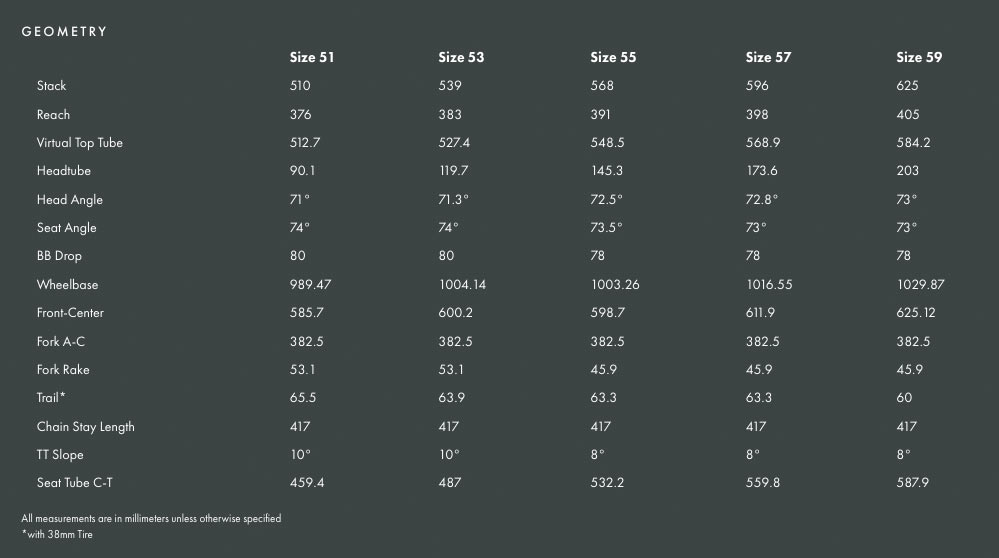

Their first bike, the Surveyor, is a racy all-road bike designed to go fast regardless of road conditions. It definitely leans more road than not, and with a max 38mm tire clearance, it’s not designed to become a gravel bike. But it is designed to tame the often less-than-ideal road surfaces of a northern city like Toronto.

The bikes are 100% designed and built in their new factory, with new equipment and processes you’ll learn more about in our pre-launch podcast interview. The official launch date is coming up, and we’ll have more granular tech details then, but key specs include:

- FRAME: BRIDGE Handmade Proprietary Carbon

- FORK: BRIDGE Handmade Proprietary Carbon

- HEADSET: In-set style

- AXLES: 12×100 / 12×142

- BB STANDARD: T47

- SEATPOST: 27.2 mm

- SEAT COLLAR: BRIDGE 27.2

- CABLE ROUTING: Fully Hidden Internal Routing

- TIRE CLEARANCE: 28–38 mm

- GEARING: 1x or 2x compatible

- WEIGHT: Approx. 900 grams

The lack of extra bosses and mounts cements its place on, well, cement. And tarmac.

The fork design, headtube and downtube shaping, and stout T47 bottom bracket shell give away co-founder Mike Yakubowicz’s penchant for racing bikes, but the overall geometry shows he also enjoys a comfortable ride more inline with most riders’ flexibility and intended use. Meaning, it’s a bike designed for all-day hammering.

They’re taking pre-orders now for framesets. Pay in full and you’ll get one of the first 50, or put down a deposit to secure one from the second batch of 50. Stock colors include blue, gray, pink, green, and tan. MSRP is $CAD 4,999 (about $3,950 USD based on current rates).

They’ll also offer custom paint schemes and color combos. Look for bikes to ship in Q2, and stay tuned for more details.