The all-new Zipp 3ZERO MOTO mountain bike wheels are a motocross inspired wheelset built around a single wall carbon fiber rim designed to act as part of your suspension. Zipp’s sole mission is to make you faster, and this unique design should do just that. But it took them a long time to get here, and a lot of prototypes.

Wait, isn’t Zipp a road brand?

They are. Or, were. Now they’re a wheel brand. Zipp’s mountain bike program actually started way back in 2012, but the technology wasn’t ready for their ideas. Some of them just couldn’t get that idea out of their heads, though, and it would occasionally get picked back up, then shelved again, then re-launched in earnest in 2016. To get to this finished product took three years of testing with more than 110 laminates, 6 resin systems and 4 different classes of fiber. In 2017 they brought in test riders like Jerome Clementz, Adrien Dailly and more, along with a mix of non-pro riders of all shapes and sizes. They had seven different prototypes for them to test, ranging from lighter weight versions to stiffer versions to other mixes of features and benefits.

Why? What’s wrong with current rims?

With alloy, you get a material that’s softer than carbon fiber, which helps make it compliant, but it’s more susceptible to dings and dents that can eventually cause air leaks. And if you really hit hard, you may end up with a bit of a flat spot.

With carbon, they’re lighter (or they can be) and they’re stiffer, but often too stiff to offer good compliance. Or, the bead wall is so stiff you need to add a little more air pressure to reduce the likelihood of pinch flats, which means traction suffers and you’re bouncing around more, which creates fatigue.

How could they be different?

For inspiration, they looked to moto. In particular, enduro motorcycle racing, which is very similar to mountain bike riding in terms of what a riders wants and needs out of a wheel. Since the advent of alloy rims, bicycle wheels have been using some sort of box section or truss design. This profile added the necessary stiffness while allowing the desired light weight. The problem with this is that aluminum is an isotropic material, meaning you can’t control the stiffness by aligning the grains since it’s equally stiff in all directions, you need to do it with the shape. But, with carbon fiber, there’s no need for a box section design because the material itself is very stiff. So, the current crop of “box section” carbon rims are essentially doubling up on stiffness and, according to Zipp, not really taking full advantage of the material’s benefits.

So, they got rid of the supporting structure and simply went with a single-wall, flat profile. To be fair, they’re not the first company to do this…Australian startup Bouwmeester launched one in 2014, but it’s founder has since been recruited by Crank Brothers and isn’t producing any new products under his own brand.

The benefit to the single-wall profile is that it allows for more radial compression, so the rim can be more compliant. But that’s not all. single-wall moto rims can flex in a way that allows the cross section of the rim to pivot around the spoke head. Zipp calls this “Ankle Flex”, and it’s essentially a torsional flex with the spoke heads as the fulcrum. You’ll want to watch our video below to learn more about this.

Zipp wraps the carbon all the way around the sidewall’s bead, providing continuous fibers (and lots of them) at the top of the impact zone. The lighter layer is a Kevlar-like material to prevent separation if you manage to destroy the rim.

Zipp wraps the carbon all the way around the sidewall’s bead, providing continuous fibers (and lots of them) at the top of the impact zone. The lighter layer is a Kevlar-like material to prevent separation if you manage to destroy the rim.For moto, they can get away with thick alloy profiles, and short spokes and lots of them. Obviously, bicycles don’t have that luxury, so they went with carbon and tuned it using different layers of carbon in different orientations.

They had to find a resin system that allowed for flex without cracking over time. It also had to be resilient enough to handle rock strikes and other hard impacts that could potentially damage a rim. They also added a layer of non-carbon material that has some stretch, which they say helps keep the rim together in the event of catastrophic failure. Meaning, if you smash your wheel so hard that the rim completely cracks, this layer will keep it from separating and exploding. So, in theory, you could bring the bike to a stop if you’re actually still on it. The likelihood of that happening? Slim, and they’re so confident you won’t break them that they offer a lifetime warranty on the rims and wheels. More on that in a minute. First, a video run through with Zipp’s lead engineer for the project:

Who are they for?

The 3ZERO MOTO wheels are aimed at the trail and enduro riders. The goal is to increase the rider’s control, and be more durable, which makes them faster. To do this, they had to nail the same three parameters as any other wheel: Lateral stiffness, torsional windup, and radial compliance. The real trick is a fourth dimension: Ankle Flex.

Ankle Flex is a localized rotational flex at the spokes that lets the rim “twist” with the tire and terrain, yet doesn’t give up the lateral stiffness. It’s inspired by how a runner’s ankle provides flex in the same plane as the direction you’re running, allowing the bottom of the foot to stay planted on the ground over uneven terrain or when leaning into a corner. Same thing here, except it’s keeping your tire’s deflection in it’s ideal direction. Another way to think of it is that the “foot” of your tire’s tread is kept in more direct contact with the ground.

Special spoke nipple washers are required and provide a stronger flex point “pivot” without letting the spokes wear into the carbon fiber.

Special spoke nipple washers are required and provide a stronger flex point “pivot” without letting the spokes wear into the carbon fiber.It also means that if you hit something hard enough to smash into the rim, it’ll flex to allow both sidewalls to hit at about the same time and share the load. The flat design also allows for more radial deflection on a big hit, which spreads the load over a larger zone.

Another benefit is decreased his frequency vibrations from low power impacts (read as “trail chatter), which is where most of our riding happens. It’s also what causes arm and body fatigue.

Photo: SRAM/Dan Hearn

Photo: SRAM/Dan HearnDoes it work?

To test this theory in the real world, we brought our own bikes to SRAM’s MTB camp in Sintra, Portugal. Day one was riding the new 2020 Rockshox forks, during which we stayed on whichever wheels we brought. Day Two was for Zipp, but we started with a couple more laps on our original wheels just to get a feel for things again. Then we switched to the 3ZERO MOTO.

The bike became easier to control through rooty, rocky, bumpy corners. Photo: SRAM/Dan Hearn

The bike became easier to control through rooty, rocky, bumpy corners. Photo: SRAM/Dan HearnAt first it was subtle, each successive lap revealing a little something more about them. After each lap, we’d take a few notes across categories like stiffness, comfort, braking, cornering, and general ride feel. It was on the last of three laps that things clicked – the main thing I noticed was the straight line stability…these wheels seemed to help me really hold a line over chundery roots and rocks. And not just a straight ine; I was able to hold my intended arc around technical corners, also riding over technical, rowdy, rough stuff.

This testing was done on the same section we had ridden for two days, so we were very familiar with the trail, using the same Maxxis tires on the same bike. The only variable was the wheels.

The wheels stayed true and were laterally stiff, making it easy to hold a line on smooth trails, too. Photo: SRAM/Dan Hearn

The wheels stayed true and were laterally stiff, making it easy to hold a line on smooth trails, too. Photo: SRAM/Dan HearnFor the final lap of this test, we put our old wheels back on the bike. The difference became much more clear. From my perspective, the original wheels (in this case Stan’s Flow), were pretty good, but definitely felt a little harsher. But the biggest difference was how much better the Zipp wheels were at tracking very straight through the rough stuff. With the original wheels, I could feel the tire being deflected off the rocks and roots and pinging me left and right. Until now, I’d just assumed this was the nature of the beast. But now, having ridden the Zipp wheels, it’s clear things can be better.

Rocky, off camber & chunky sections became far more manageable with the Zipp 3ZERO MOTO wheels. Photo: SRAM/Dan Hearn

Rocky, off camber & chunky sections became far more manageable with the Zipp 3ZERO MOTO wheels. Photo: SRAM/Dan HearnFrom our guide’s perspective, who was riding behind me for a couple of test laps, I rode much more confidently with the Zipp wheels. Less nervous. And was able to choose better lines. Our consensus is that when you’re not having to worry about controlling the bike so much, your mind is freer to scan ahead, pick better lines and just flow through the trail faster and more smoothly.

That’s great, but what about XC? or DH?

These rims are too heavy and too wide for XC, and they know that. And they’re not sure the single wall design would work as well for narrower rims. Nor are they up to downhill racing standards. But they had to start somewhere, so they went where they thought this application had the biggest benefit for the largest number of riders. Chances are pretty good they’re looking at these categories, too, though.

3ZERO MOTO wheel build details & specs

The Zipp 3ZERO MOTO’s name comes from the width, 30mm internal, borrowing (and modifying) the depth-based naming convention of their road wheels. External width is 37.5mm.

Complete wheels are built on their ZM1 Hubs and laced up with 32 spokes per wheel. Why 32? Because they wanted the wheels to be very strong, and the extra spokes give them the lateral and torsional stiffness they need, but still allowed the radial compliance and ankle flex they wanted.

They’re 6-bolt rotor only, likely because a Center Lock rotor won’t fit over the Torque Cap end caps on the front, so this makes it easy to just offer one thing that works for everything.

Inside are 26 teeth with two sets of offset pawl pairs to create 52 points of engagement. That creates a ~7º engagement, which is acceptable. I gave it a few stutter stops on a climb, mimicking what it’s like picking my way over a technical section, then a few coast-to-sprint efforts, and it felt quick enough. I’d still prefer 5º or less for mountain bike, but I never felt like it was too slow to engage.

Everything’s rolling on standard cartridge bearings. Hubs are Boost only for now, which is partly why they’re offering standalone rims, too, so you can build them onto standard or Super Boost hubs as needed.

What’s that thing on at the valve stems?

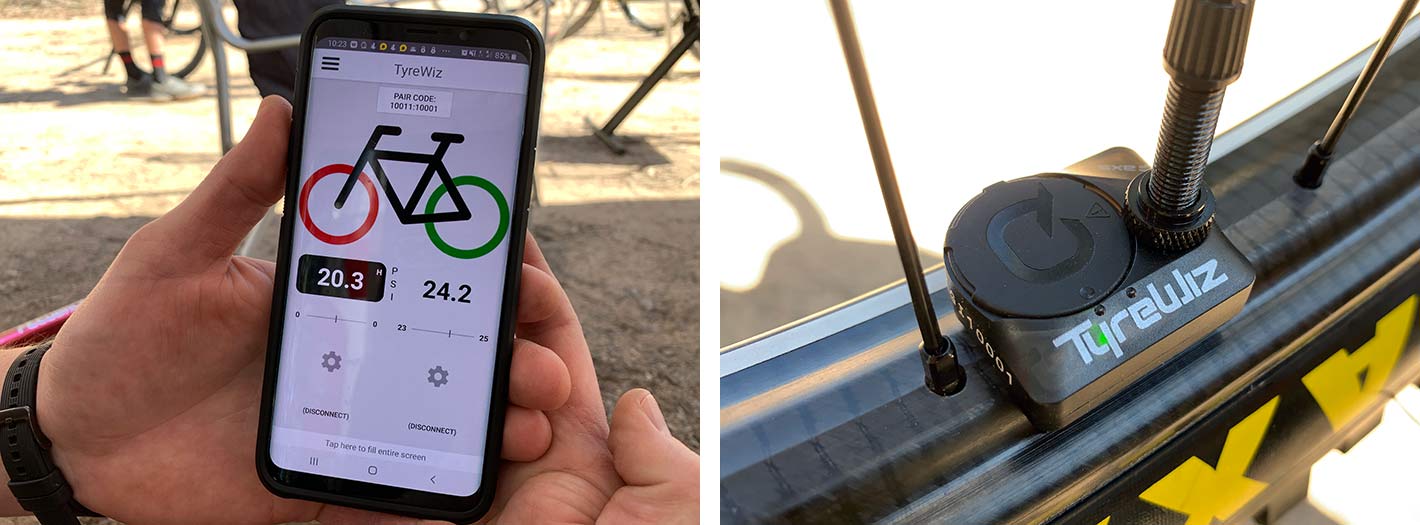

Complete 3ZERO MOTO wheels will come with Zipp’s TireWiz, which has been modified to sit flush on the rim’s profile. TyreWiz is their ANT+/Bluetooth-enabled tire pressure monitor, and it’s not as ridiculous as we first thought. Yes, there’s an app for that, but it’s getting rolled into the SRAM AXS app. It’ll also send your tire pressure data to Wahoo and Garmin cycling computers, so you can see it in real time.

But for us, the neat thing is just being able to see if your tires are at the right pressure without ever having to look at a screen. Once you set up the desired range in the app, the TyreWiz remembers that and blinks green if it’s in range, or patterns of red if it’s over or under. So, at a glance, you know if you’re ready to ride. They’re accurate to +/-2% all the way down to 0psi.

What do they weigh?

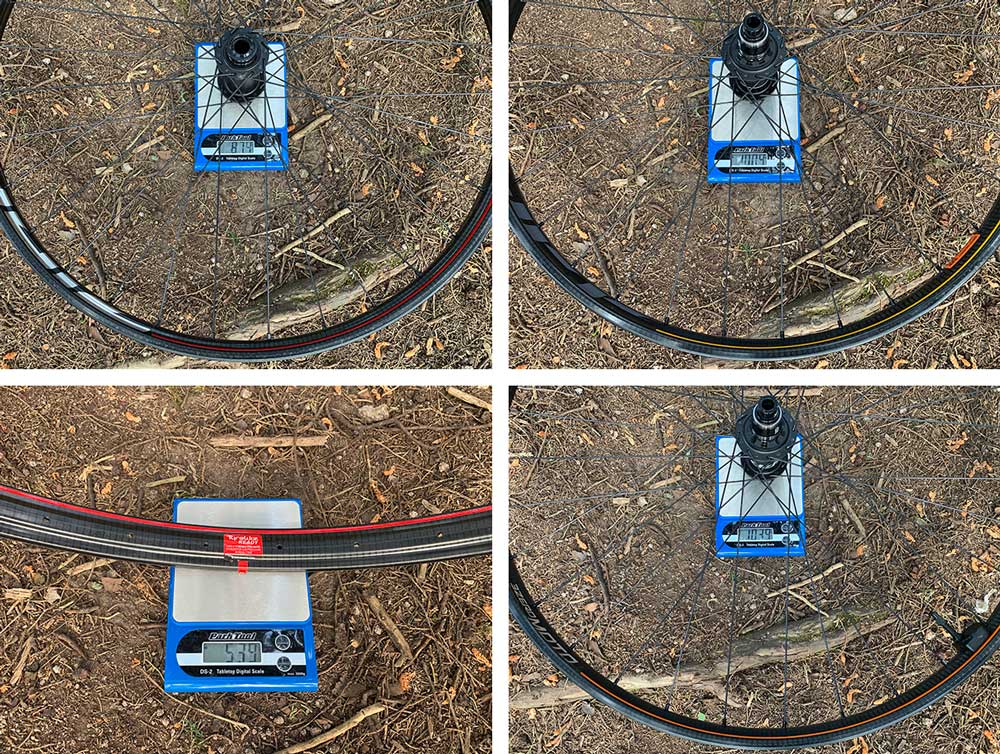

Clockwise from top right, actual weights are 874g (27.5″ front), 1004g (27.5″ rear), 1039g (29er rear) and 539g (27.5″ rim). The 27.5″ rim and 29er front wheel weren’t available on their own for weights, but assume about 25g (rim) and 35g (wheel) difference between sizes based on measurements shown here.

Claimed weights are:

- 27.5″ – 850g F / 975g R / 1825g set

- 29er – 895g F / 1015g R / 1910g set

- Rims – 535g 27.5″ / 565g 29er

They’ll come with the silver Zipp logo, with your choice of rim ring decal colors: Silver, Stealth, RS Red, Orange, Yellow, Green, Teal or Blue. Don’t want any? Just peel it off.

I want. When can I get it?

The wheelset will retail for $1,999 (€2,099 / £1,875) and are available now. Complete wheels ship with tubeless valve stems, pre-installed tubeless tape, and the TyreWiz on for both wheels. They’re Boost thru axle only, and the front wheel includes both standard 21mm end caps and the 31mm diameter Rockshox Torque Caps.

Rim only price is $700 (€750 / £670) and comes with the tubeless set up parts and washers, but the TyreWiz monitors are a $200/pair add on. You can pick the decal colors, but they only come in 32-hole drillings. They also have specific spoke and nipple recommendations for your wheel builder to use.

They come with a non-transferable lifetime warranty, unless you use it with a double crown fork…which will void your warranty. Or do something stupid outside of their intended use. But basically, if you wreck them during normal trail riding or enduro racing, you’re covered.

Stay tuned to the Bikerumor Podcast for an interview with Jerome Clementz about how he helped test these wheels, the development process and more!