Fresh off some Kansas gravel racing, Fulcrum officially unveil their all-new Sharq aero carbon wheels. But Fulcrum says they’re not just for gravel, instead designing the Sharqs in their Red Room R&D Lab to make all road riding faster – from tarmac to dirt. Not the first to turn to biomimicry inspiration to optimize wheel aerodynamics, the Fulcrum Sharq takes a bite out of the wind with a unique 3-dimensional wavy sharktooth design.

Fulcrum Sharq aero carbon road & gravel race wheels

Wavy wheels already stand out from the crowd, but these new Fulcrum Sharq take it to the next level with what they call their “2-Wave” design. Instead of just varying the depth of the centerline of the rim like we’ve seen from other wheelbuilders, these wheels feature a much more complex shape to cut through the wind.

Fresh off Unbound where Mattia De Marchi rode the wheels to a 5th place, it’s apparently Fulcrum’s 20th anniversary. And they’re saying these new wheels are officially the first they’ve designed “specifically for endurance and all road use“. That’s definitely not to say they aren’t race wheels, just that the don’t really pigeonhole themselves as either road or gravel. These are aero fast in-betweeners, developed to make pretty much every dropbar bike ride faster.

OK, so what the real deal with the shark teeth waves?

What’s new with the Sharq 2 Wave?

The 2-Wave rim is what’s really new. The Sharq’s patent-pending wave shape undulates slightly from a direct side-on perspective. It is 47mm deep at the spokes, but 5mm shallower in between.

But the truly unique element is how the second wave is shifted and offset in 3D, as it moves away from the centerline of the rim. The result is that the rim section varies from a more flat-sided blunt-nose profile at the spoke, to a slightly more V-shaped aero profile about 1/4 of the way in front of the spoke at the bottom of the wheel.

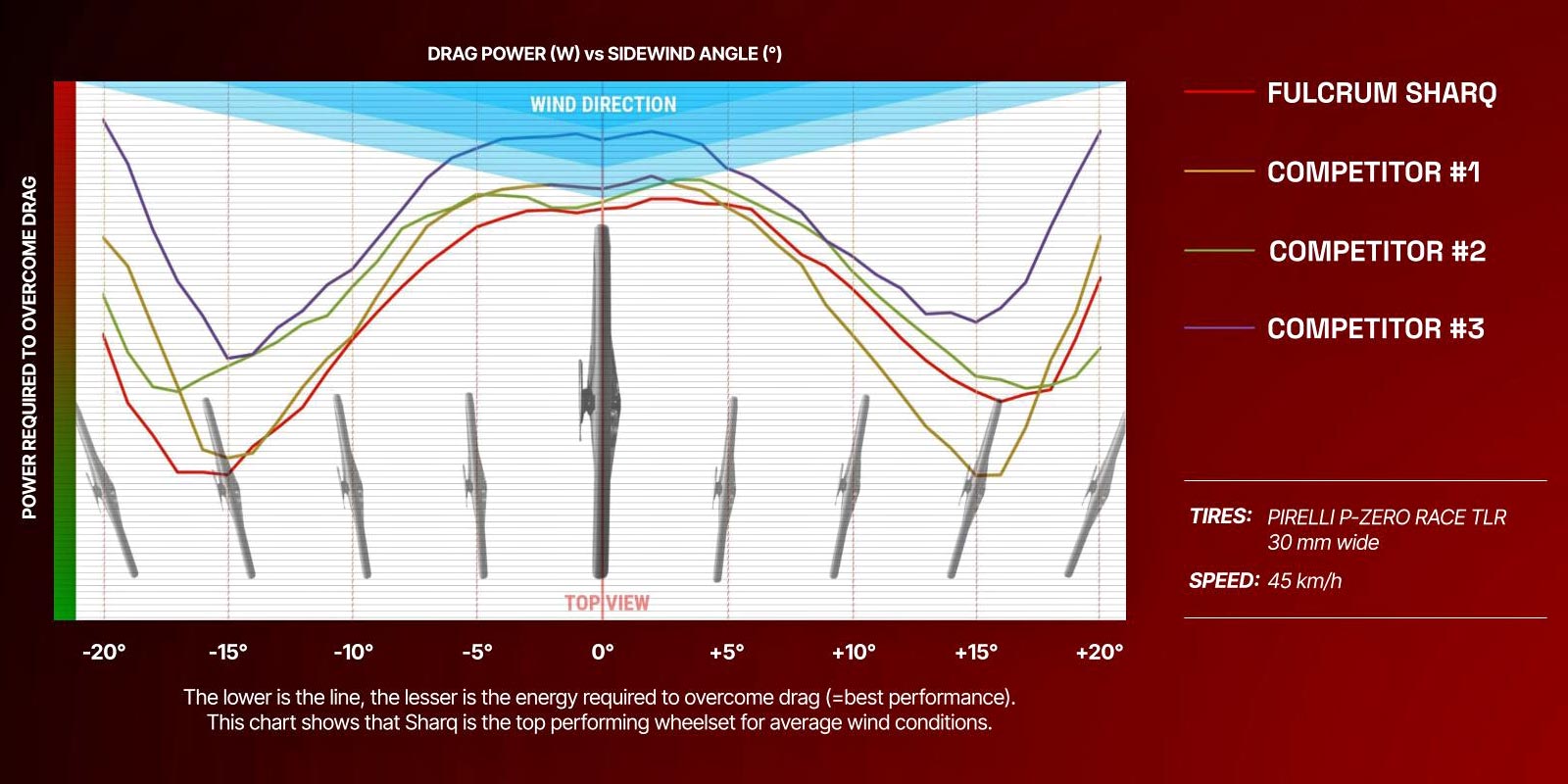

Fulcrum explains that this special 3D asymmetrical design better manages airflow over the carbon rim and wide tires, both reducing aerodynamic drag directly into the wind and in crosswinds. They claim a “21% improvement in winds from 0° to 10° and up to 30% between 10° and 20°” vs. a traditional aero rim profile of the same depth.

New A3RO spokes, too

Keeping the new wheels serviceable, Fulcrum builds them with external nipples and new straight-pull stainless steel spokes. Which does mean they are now proprietary. Those spokes feature a new butted and bladed profile that is 3mm wide x 0.8mm thick in the center. And they get a semi-cross-shaped shoulder on the round spoke head to sit firmly in the matching hole in the hub without rotating.

Tech details

Fulcrum makes the new Sharq rims with a new proprietary FF100 mix of carbon and resin for lightweight. And they’re able to lay them up precisely so there’s no finishing require when they come out of the mold – just laser-etched graphics and water-transfer logos.

They give the Sharq a 25mm internal width, with a mini-hook that ensures safe compatibility with all tires 30mm and up. And it fits with their secure 2-Way-Fit tubeless or tube-type concept. No drilled holes for the alloy nipples. They are guided into place with a magnet for wheelbuilding. That means a permanent tubeless-ready setup without relying on tape.

Outer rim width is 29.8mm, and the rims vary from 42-47mm deep. The alloy centerlock disc hubs feature classic cup & cone USB ceramic bearings for “extremely precise preload and maximum smoothness“.

Complete wheelset weight is claimed at 1440g.

Fulcrum Sharq aero wheels – Pricing, options & availability

Fulcrum’s all-new carbon Sharq aero wheels sell for $2807 / 2460€, and are available now. Tubeless ready out of the box without rim tape, the wheels come with tubeless valves and wheel bags.

Pick from Shimano HG, MicroSpline, SRAM XDR & Campagnolo N3W free hub bodies, then fit them to your road or gravel bike to go faster!