We first got eyes on an early version of the Galfer Disc Shark rotor in July 2021 when Galfer engineer Ricard Bagés Estopà stepped up to answer some of our readers’ questions on brake fade. That teaser prompted us to find out more about the prototype rotor that was created specifically for the Commencal Muc-Off DH team who wanted “a custom disc that would resist excessive temperature increases under braking on some of the steeper tracks of the World Cup circuit”.

At the time, Galfer had no plans for a production version of the rotor, but it seems appetites have changed. The Galfer Disc Shark Brake Rotor is now available to Joe Public in 180mm, 203mm, and 223mm diameters.

Galfer Disc Shark Rotor

The use of cooling fins in brake technology is nothing new, of course. Shimano offer a premium finned brake pad option, said to increase heat dissipation, as do numerous aftermarket brake pad manufacturers such as Stop Components and SwissStop.

It’s not the first time we’ve seen the use of fins on the rotor itself, either. Shimano’s Ice Tech FREEZA rotors are probably the most mainstream of the lot, featuring a thin layer of aluminum sandwiched between the steel braking surface that extends out toward the center of the rotor, where its large surface area-to-volume ratio allows it to act as a heat sink, pulling heat away from the braking surface, and thus the brake caliper itself. As well as cooling fins, brands have also resorted to various heat-dissipating paints, as seen on SRAM’s HS2 rotor.

Despite their various forms, the abovementioned technologies all work to achieve the same thing; lower temperatures at the rotor under sustained heavy braking. Reduced heat means less brake fade, thus more power and consistent braking further down the race track. This is what the Commencal Muc-Off team were after when they approached Galfer.

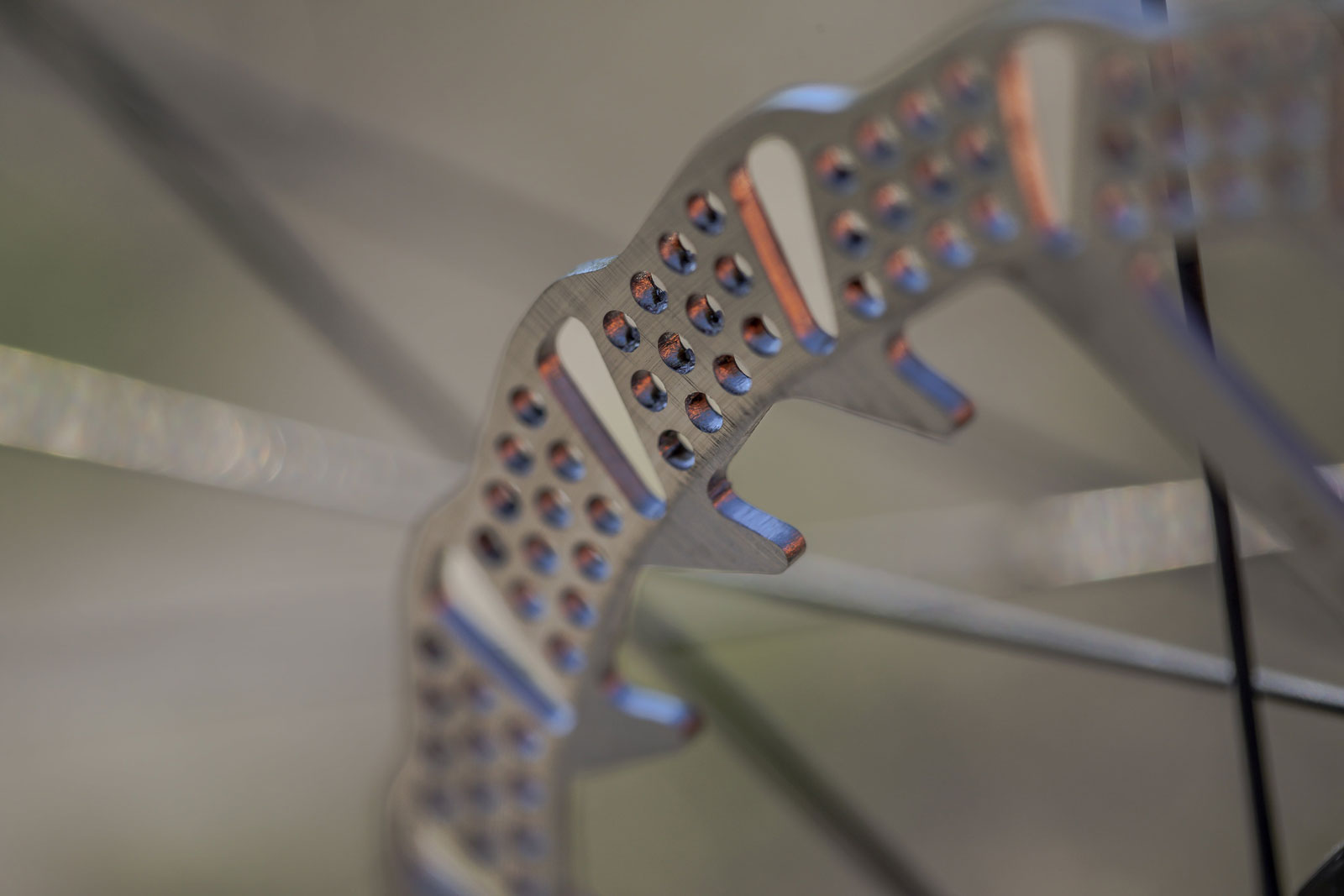

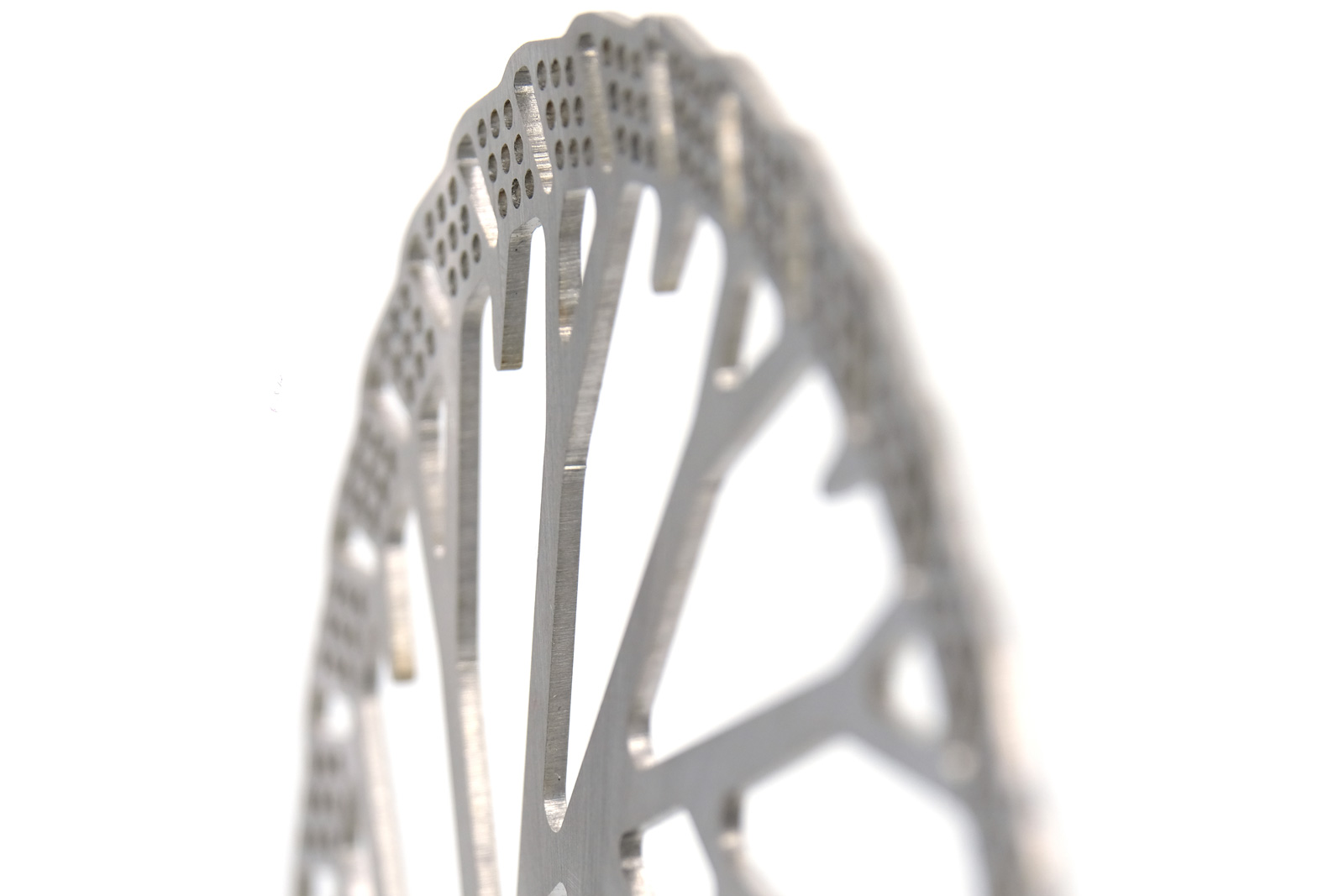

The Spanish brand’s solution was the finned one-piece rotor you see above. That prototype has evolved into the production Disc Shark seen below, with a laser-cut brake track that sees less material than that of the prototype raced by Myriam Nicole and Amaury Pierron.

Galfer engineer, Ricard Bagés Estopà, tell us that while the race team’s finned rotor was made specifically to reduce temperature, the production disc has been further developed to improve bite power and stiffness. The larger windows cut out of the brake track address the former, while the increased number of ‘legs” extending from the center out to the brake track are said increase the rotor’s stiffness to resist warp.

While the Commencal Muc-Off team rotor was limited to dry, hard-pack usage only, Ricard tells us this production disc can be used in all conditions, though it excels in dry, hot conditions. For extremely muddy conditions, they still recommend the Galfer Disc Wave rotor, which features much bigger windows to help keep the brake surface clean.

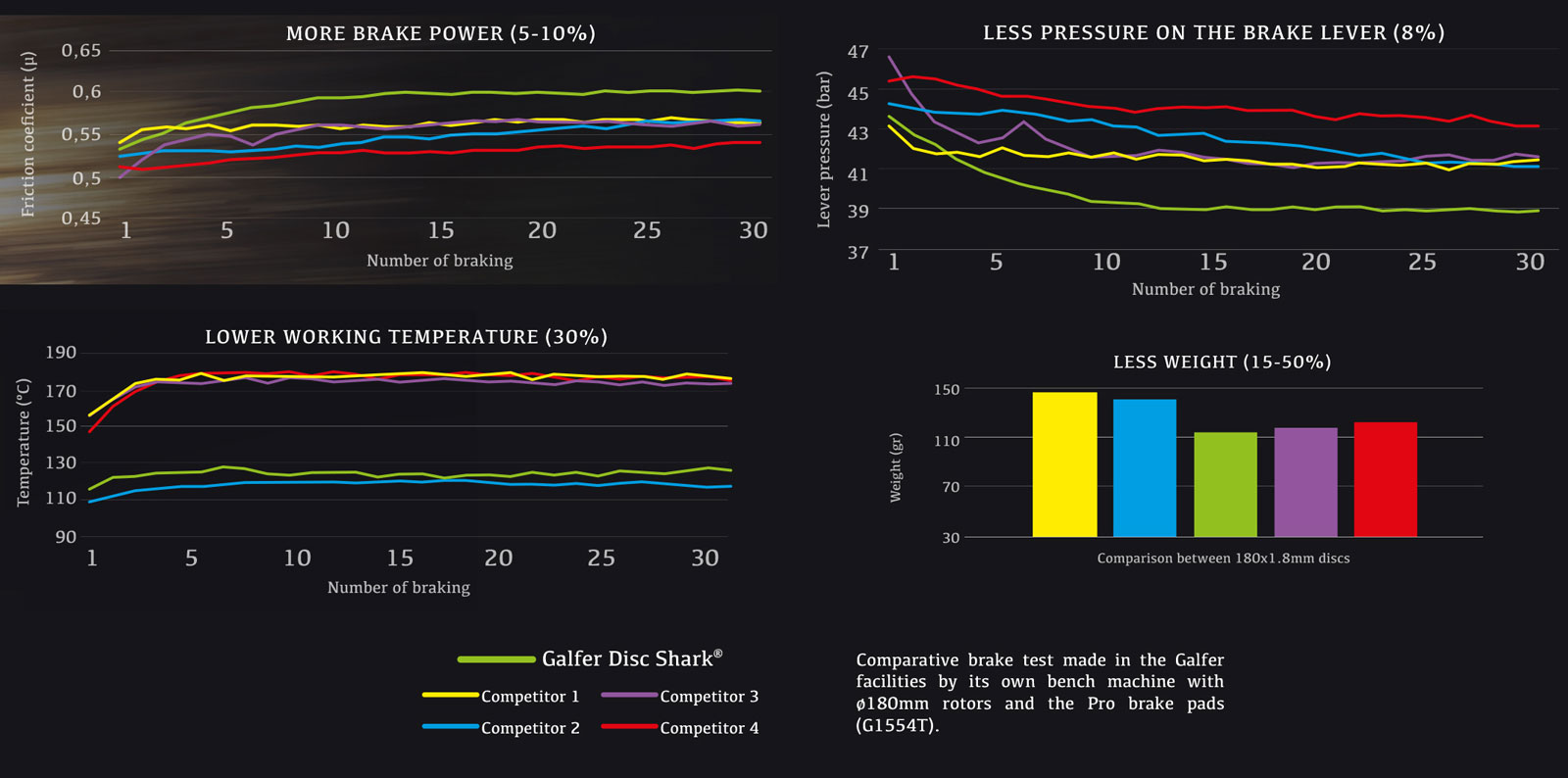

Galfer has tested the Disc Shark rotor against four unnamed competitor discs. Despite being the thickest rotor, at 2mm thick, the Disc Shark claims to be the lightest of its competitors, weighing a claimed 127g for the 180mm diameter option. According to Galfer’s in-house testing, only one of its heaviest competitors has a lower working temperature, while it was shown to offer the highest braking power (after 3 cycles) as measured by the friction coefficient. It was also shown to require less pressure at the lever for the same braking power.

Another claimed advantage of the Disc Shark is that it allows brake pads to last longer. Galfer claim that, under normal conditions, brake pad life is increased by 25-40% with Disc Shark.

The Galfer Disc Shark has applications outside of DH racing; it is also rated for enduro and eMTB. Though it can’t be seen on any of the pictures here, there is apparently a small hole positioned for use with the magnet required for eBike speed sensors.

Pricing & Availability

The new Galfer Disc Shark brake rotor will be available from June 2022 in 6-Bolt only, in the following sizes:

- DB0223W2 (ø180 x 2.0 mm – 127 g): €85 + VAT

- DB024W (ø203 x 2.0 mm – 174 g): €90 + VAT

- DB027W (ø223 x 2.0 mm – 237 g): €95 + VAT