These prototype Hope RXCranks are designed for road or cyclocross because, in their words, they “wanted to create a stiffer crank than what they’d done before, and than what’s out there, but in aluminum.”

Arms are hollow, two piece bonded construction where the main body is machined from a single piece, then with a back plate bonded on to cover the channel that’s machined out. But it’s not just a cosmetic cover plate, it’s a structural element that creates a box section.

This makes it far stiffer torsionally than a C section crank, which is what they would have had if they left it open. They machine rather than forge because A) that’s what they’re known for, and B) because it lets them control the shape and contour of the arms on the inside to maximize stiffness.

It’s built on an alloy 30mm axle. The spindle is wider than a typical BB30 spindle, pushed out to the same width as a 24mm spindle. That lets them use it on virtually any frame, including BBright and BB386EVO, but still have the same Q-factor as most other cranks.

It’s still in development, but aiming for ~500g with a spider. It has the same interface as their MTB cranks, so you could use their direct mount rings, and they’re working on a direct mount chainring system for the road and a single ring for cyclocross.

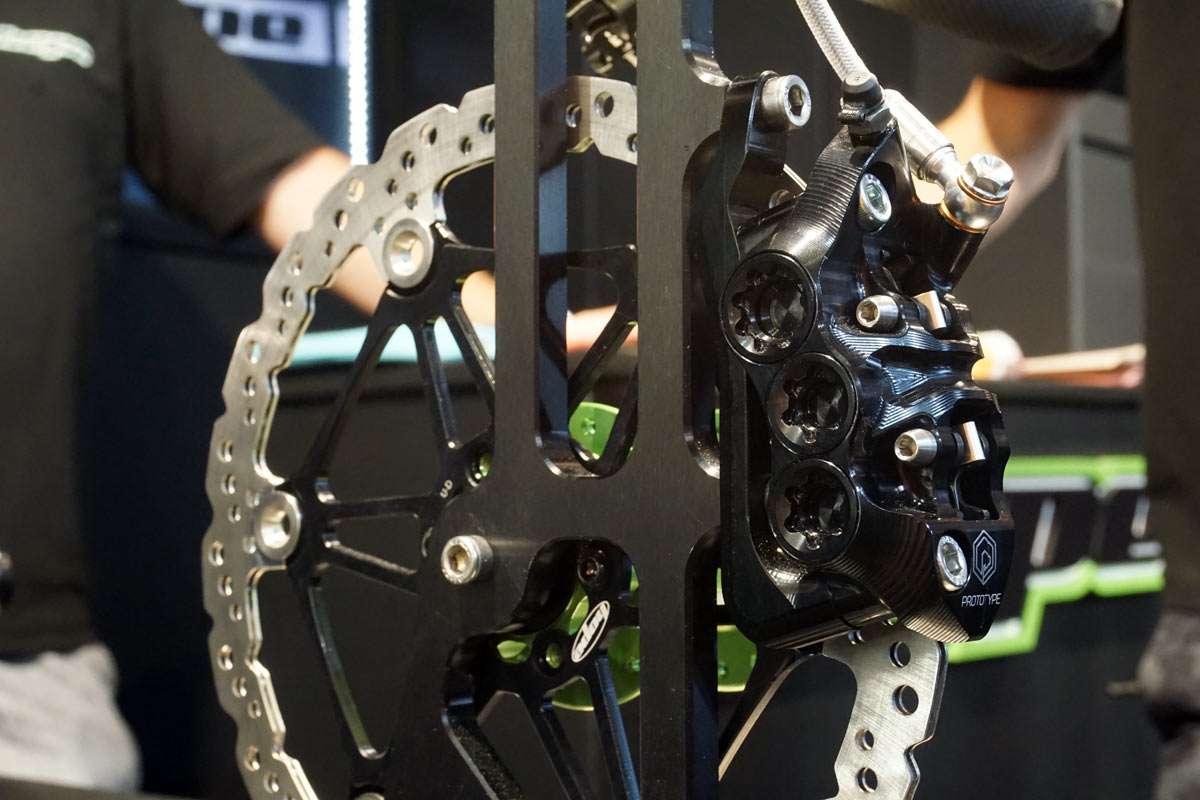

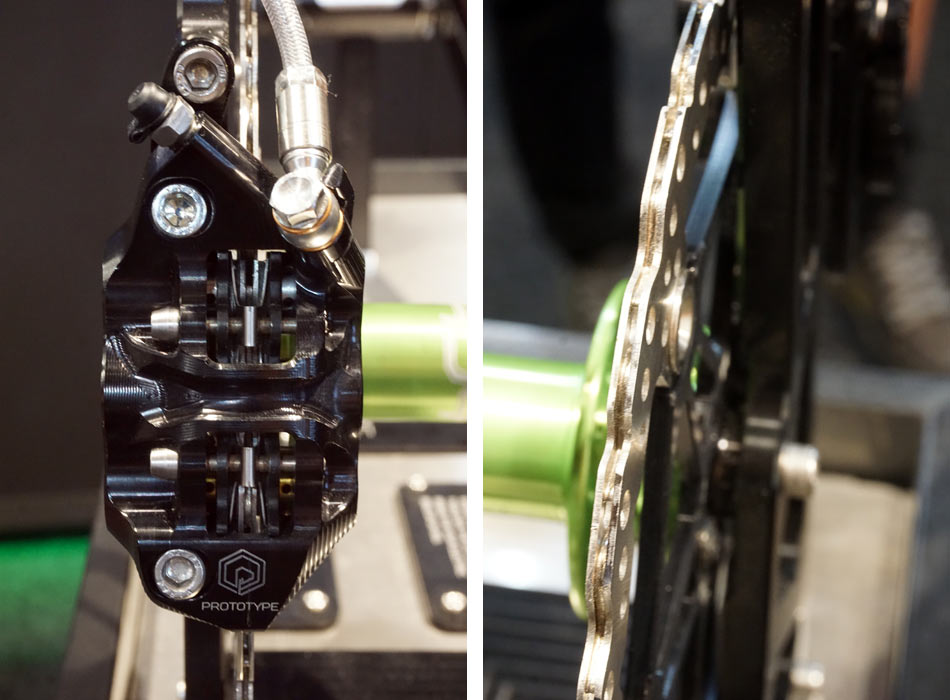

Their VR4 flat mount disc brake calipers were unveiled last year, but they’re still not quite through production. But that didn’t stop them from setting a pair up with the new Campagnolo disc brake group.

Even bigger news, literally, is the revival of their V6ti brake caliper. This is still in prototype phase, but it’s a six-piston brake with massive power. It has titanium pistons, which they say do a good job of shedding heat, but cost too much for their higher volume brakes. They say Ti works about as well as the phenolic pistons used in their other brakes, but the quantity is to low to produce phenolic pistons here, but it’s easy to machine a few titanium ones.

It’s a radial mount, meaning it mounts straight out from the fork or frame rather than being offset to adjust for rotor size. So, you’ll need spacers to adjust for rotor size. It’ll work with their vented rotor (shown) or a standard one. Aimed at e-bikes and downhill mountain bikes where you need more power.

Hope HB.160 UK-made carbon enduro bike

Their HB.160 full carbon trail bike, which they’ve been working on for quite some time as a test bed for producing carbon parts in house, is finally shipping. It’s only sold as a complete bike, with your choice of seven anodized hardware colors to match the rest of their components.

The bike retails for £7,500, and it’s in limited supply because they can only make 4 bikes per week. Part of that time consuming process is because the carbon is lined up to match on each half of the frame.

The handlebar is £160. Both are in limited supply.