Lizard Skins has been around for a long time, thanklessly making sure your hands stay where they’re supposed to when gripping everything from bicycle handlebars to hockey sticks and pickleball paddles. What I’m saying is that Lizard Skins knows a thing or two about grips. Keeping up with the times, they’re introducing their latest, and super high-tech bicycle grip, the 3DGRP.

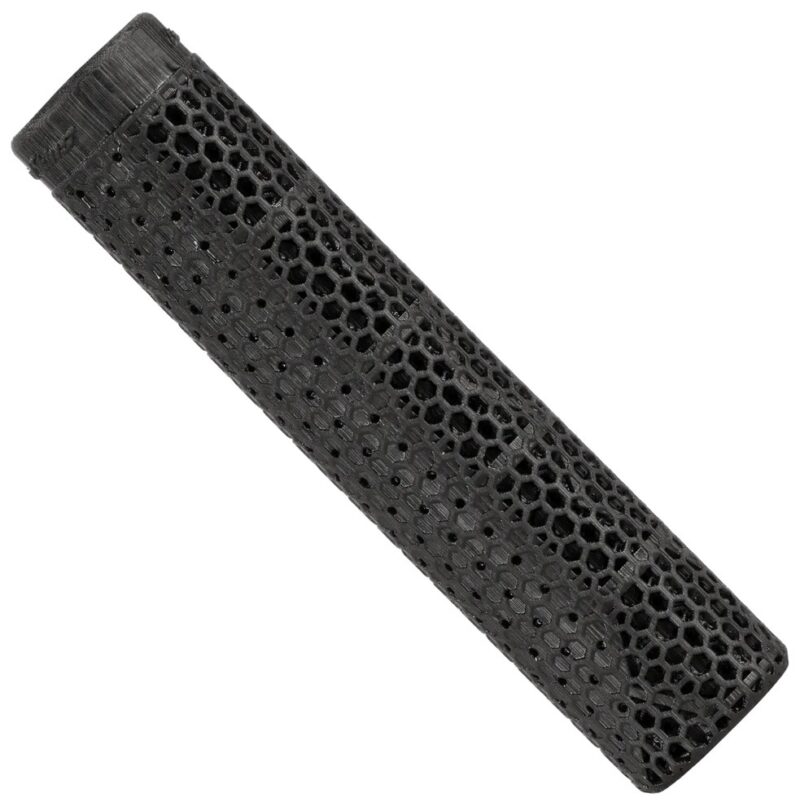

The new 3DGRP grips are created by Carbon utilizing their Digital Light Synthesis technology. “DLS is a production method using programmable liquid resins, digital ultraviolet light projection, and oxygen permeable optics to create pieces with superb performance and surface finish“.

When using these types of advancements in 3D printing, the development of the Lizard Skins 3DGRP was unrestrained by traditional manufacturing methods and materials. And they think that the 3DGRP grip will help you take your ride to the next level.

Look How the Lizard Skins 3DGRP Is Made

It’s been pretty quiet over at Lizard Skins since it was announced that Fox Factory was set to purchase their parent company Marucci, though they seem to still be innovating. For those unaware, Carbon is the 3D printing company that has been partnering with a number of cycling brands to create new products including Specialized and Kú Cycle.

It makes sense then that the 3DGRP lattice looks similar to that of the Specialized 3D printed saddles. It will be interesting to see how the material and pattern holds up when used as a grip. Between all the holes and the fact that they’re not lockons, these had better be really comfortable to justify the price. But if they are anything like those 3D printed saddles, they’ll probably end up some of the most comfortable grips ever.

The 3DGRP Retail and Specs

Retail: $51.99

- Total Weight: 68 grams / 2.39 ounces

- Length: 133 millimeters / 5.11 inches

- Diameter: Medium (32 millimeters / 1.26 inches)

- Compatible with MTB, BMX, ATV, and PWC