The new Boyd Cycling Eternity hubs push bearings and flanges wider than ever to create a super stiff wheel, and the unique stacked axle system helps it roll smoother by effectively disengaging two of the four bearings when pedaling.

Founder Boyd Johnson says the hubs offer the widest flange spacing out there, especially at the front, where there’s 80mm from center to center of the flanges. Out back, he says most hubs have between 50mm and 55mm between rear flanges, but the Eternity hub pushes that to 56.1mm from flange center to center. The driveside flange is pushed to 18.1mm from hub centerline to flange center, which Boyd says is the widest that can be used on a modern 11-speed drivetrain. And it’s all optimized for both stiffness and tension with a traditional lacing pattern.

Those wider flanges create a wider base, improving triangulation. That means a stiffer “pyramid” peaking at the rim, which translates to less rim deflection under cornering loads. But that’s just part of what makes a stiffer wheel, so let’s have a look inside and see what else makes them special…

On both front and rear, the hubs use what’s essentially a thru-axle design, but it still clamps with a skewer. On both wheels, the dropouts are resting on the axle…there are no end caps. This makes the axle as wide as possible, running from end to end, and the bearings are pressed on top and set very wide to make the system a lot stiffer. Shown above is the Boyd Eternity axle on the top compared to a traditional front wheel axle.

“Another benefit to that is when we do the preload over the axle, it makes it harder for water to penetrate the system,” Boyd said. “Which prolongs the life of the bearings and the hubs.”

The image above shows the axle with preload caps snugged up to the bearings. They thread into place to adjust the preload, then a set screw locks them into position. Bearing width on the front hub is 74mm center to center.

Boyd: “The rear hub has 49% of the tension on the non-drive side, making it virtually even from side to side. That’s with traditional, double cross 24 spokes putting 12 on each side of the wheel. Once you get above 59kg of force per side, it’s enough to keep the spoke nipples from loosening, and going much above that doesn’t do much to increase overall wheel stiffness.

“If a wheel builder wants to do “triplet” lacing (8 on non-drive, 16 on drive side), we could make a new shell with an even wider flange spacing that’s optimized for that lacing pattern, but I’d caution that with just eight spokes on the outside, if one broke for some reason, it could ruin the ride home.”

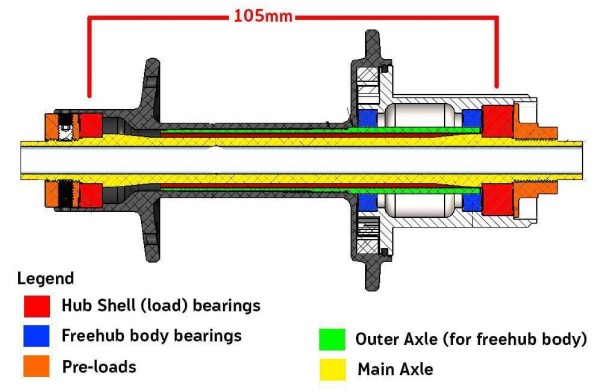

The rear hub gets even more creative with its axle system. There’s still a single axle (yellow) that runs all the way through the hub into the dropouts, just like the front, except this one’s a leggy 143.75mm. And the main bearings (red) sit on that axle, pushes as far out as possible.

“On the rear, the bearing placement we have is by far the widest in the industry,” says Boyd. “And when we talk about bearings, there are two types in the rear: the freehub bearings, which just make the freehub body spin, and the hub bearings that actually support the wheel on the axle. We made it so the freehub body sits on the hub shell rather than on the axle. So when you’re pedaling, both the freehub body and hub shell spin at exactly the same rate, so the freehub bearings (blue) are not spinning, which cuts bearing drag in half when pedaling. The freehub body becomes an extension of the hub shell, and so the load is spread 105mm apart.”

The Outer Axle (green) threads into the hub shell, and the freehub body rests on that. Boyd says the design allows for quick, easy freehub body removal for cleaning and greasing -about 30 seconds- as all driveside bearings are pressed into the FH body and pull off as a unit.

They use a titanium freehub body, which isn’t a new concept, but the way these are made is. Instead of machining the part from raw billet, these are injection molded, which yields a FH body that’s about 99% done when it pops out of the mold, requiring minimal post-production finishing before tapping in the bearings and installing it. Basically, they inject a liquid 6/4 titanium slurry into the mold, cool it through a proprietary process that the supplier won’t even fully divulge to Boyd, then pop it out and put everything together.

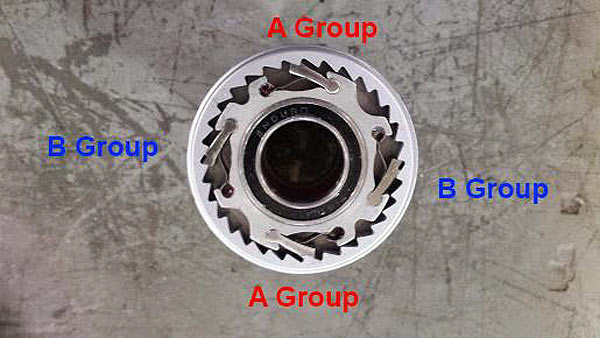

Inside the freehub is an A/B, two-step pawl mechanism that engages four pawls at a time, but only one notch on each pawl. A second notch is clocked to engage at the next half step, effectively doubling the number of engagement points. The result is a 5.6º engagement thanks the A-B, two-step pawl.

The pawls and driver ring are made of hardened, heat-treated A2 steel, which is very hard and very durable. Those parts are then electroplated to reduce friction by creating a super smooth, durable coating on both surfaces, then they’re lubricated with a special grease from NixFrixShun (one of our favorite chain lubes).

The front hub is a claimed 100g, rear is 224g. The complete hubs shown above are preproduction with an temporary alloy freehub body, but weights are with a titanium one.

There’s not a single washer or spacer anywhere in the hub…only the parts that actually serve a purpose, which means easier servicing, but more importantly, fewer things to be loose, out of tolerance or otherwise diminish performance. They’re 100% made, designed, engineered and manufactured in the U.S. He found a CNC manufacturing partner in Pennsylvania, and Boyd Cycling is based in Greenville, SC.

Retail is $580 for the hubset, available aftermarket and as complete wheels, starting to ship end of March.

Disc brake models are in development, and will be available with either these QR axles or a different, thru-axle specific design.

And the rear’s bracing angle and flange spacing will actually improve a bit with the move to disc brakes because, as Boyd explains, they have room to put disc brake mounts on this design already, but when you go to a 135mm rear spacing for disc brakes, there’s even more room to push the non-drive flange out. Look for the disc brake versions just before Eurobike in August.