Fifty One liked their original road bike, so they wanted to mimic the design of it, but take advantage of the opportunities disc brakes offered. Wider stays, thru axles, etc. In particular, they liked the the Deddaciai split stays used on their rim brake models, so they tapped a few well known carbon experts to help them optimize for disc.

Kevin Quan, who’s done work for Parlee, Diamondback and others, did the design work, then Jason Schiers (original founder of ENVE) helped get them to production.

They designed their own dropouts and flat mount brake mounts, too, creating a completely proprietary rear triangle that fits up to a 33-34mm tire. Then they pair that with Columbus forks for road or the Dedacciai gravel fork. This orange bike was built as a “gravel bike”, though it’s limited to cyclocross tires.

Fifty One uses Plasma Appelation Treatment to zap all the epoxy off the top layer of the tubes where they bond tubes together, ensuring they’re supremely clean for a much stronger connection. They use ENVE and Dedacciai tubing thru the rest of the frame, using a tube to tube construction to make it fully custom. Frame weight is about 800-850g.

$7,500 frame fork and headset which includes full custom paint, as extravagant as you want…or you can go full monotone with paint-matched components. They’re all handmade in Dublin, Ireland.

Following Campagnolo’s lead, Silca ran a contest at the show for best use of their equipment. As such, there were numerous paint-matched floor pumps, but a couple brands took things to the next level. Fifty One matched both floor pump and frame pump, using a paint scheme inspired by sunset in Toronto and the way the light hits a certain well known building there.

Wanna see more? Check our pre-show interview here, then give ’em a visit at FiftyOneBikes.com.

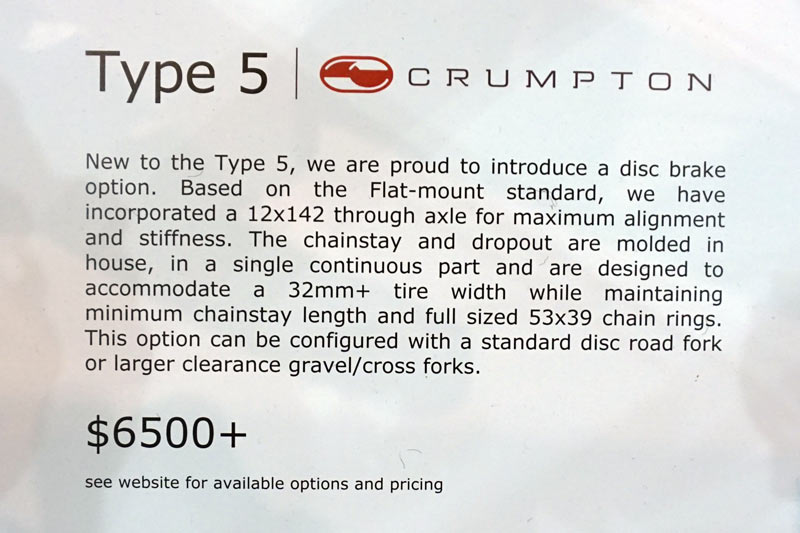

CRUMPTON CYCLES TYPE 5 DISC

Type 5 Disc is the result of the plastic prototype we saw two years ago. These are the first disc brake bikes he’s done, which took much longer than anticipated thanks to Nick’s ambitious aesthetic goals with little regard for manufacturability. He wanted minimalist dropouts that looked ultra clean.

Working our way back to those dropouts shows off the cosmetic outer layer that keeps scrap carbon from going in the landfill, but also provides a boundary layer for protection that Crumpton says has some functional manufacturing benefits he’s reluctant to publicize, too. He rolls his own tubes -each bike starts as rolled up prepreg sitting in a freezer- and makes everything but the fork.

Tire clearance is a healthy 35+ mm in the back, which means you’d have to consider a gravel road fork if you want something bigger than a 32mm tire in the front with the standard ENVE Road Disc fork.

The non-drive side’s flat mount brake section is virtually flush and hollow, yet designed to handle all the loads of disc braking.

Raw frame weight is 744g before paint, about 850g after clear coat and detail paint…for a size 55.

Retail starts at $7,000 (for the disc brake model) with a seven month lead time as of this post going live. Get on the list at CrumptonCycles.com.