Neko Mulally’s Frameworks Racing project has a new steel, carbon & alloy DH bike to race featuring a Reynolds 853 steel Cotic front triangle, developed to outperform the aluminum front end of last season’s race bikes. After racing on big-name factory teams including Intense, Trek & YT, last year 3x US national DH champ Neko Mulally set out to race on his own designed downhill bike. What started as an all-aluminum affair has been upgraded for the 2023 race season in carbon, alloy, and UK-made Cotic steel…

Frameworks Racing x Cotic 853 steel DH bike project

Long story short, last season Neko Mulally created his Frameworks Racing DH project to custom-develop his dream downhill racing bike.

With the Horst-link suspension design and adjustability just how he wanted it, the Frameworks Racing team raced aluminum prototypes across the World Cup & World Championships in 2022.

But the alloy just wasn’t delivering at the top level, and Mulally’s team was plagued by stress cracks up front and not as much stiffness & reactivity in the rear like they wanted. So it was time to go back to the drawing board a bit. A move to develop carbon chainstays & seatstays was already in motion mid-season, yielding a ridable rear end earlier this year.

But it was also time to switch up materials in the front triangle too.

This time, Neko caught up with Cy Turner, founder & director of Cotic Bikes to create a front end in steel.

Why Steel?

While aluminum seemed like the best option last season, the high stress of DH racing resulted in stress & fatigue cracks that would have taken much more development to iron out. It seems like Frameworks Racing has their eye on carbon down the road, but the upfront costs and development time rules out carbon production, at least until they finalize everything.

But Cy Turner dug into the details, ran the numbers, and realized he could build a stiffer Reynolds 853 front triangle than what Frameworks was racing in alloy, and it could be a much more robust bike.

Development & Tech Details

Starting with a lot of 853 steel tubing that Cy had already used in the development of Cotic’s steel RocketMAX enduro bike, he recreated the same geometry and suspension layout that Mulally & Frameworks had developed in more durable steel – 63° head angle mullet bike with 203mm of rear wheel travel. While Cy did the design work, Dan Roberts from RAAW bikes backed up all the calculations with design engineering reviews. Dan also was the one who engineered the new carbon stays that get bolted to the Cotic front end.

Cy combined a gen 4 RocketMAX downtube & seattube with a 2-wall-thickness thicker round toptube and the same ZS56 straight headtube that Cy used with an angle-adjust headset to dial in the latest, longest RocketMAX’s geo. On top of that are a bunch of gussets to reinforce the high stress joints. Most obvious are the big plates on the side of the headtube & the trimmed-down braces around the seat cluster, but there are also gussets at the top& bottom of the headtube – all with open corner designs that Cotic has refined since their first full-sus mountain bike back in 2006.

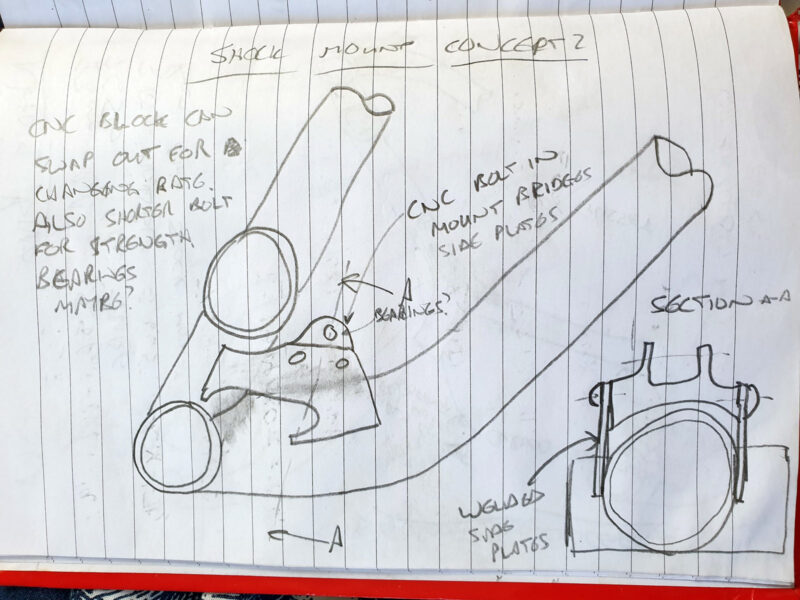

Finishing out the details, the bike gets tough enduro bearings pressed into a cup in the bottom of the seattube, some ISCG tabs around the threaded bottom brackets, and a reinforced lower shock mount assembly that allows Frameworks Racing to tweak the suspension. The “shuttle-type” design allows the team to flip the lower alloy shock mount insert to “reduce or increase the rising rate of the frame” or even bolt in another ‘shuttle’ for more shock rate tuning.

Complete carbon, steel & alloy World Cup DH bike in Stormtrooper White

The final front triangle was fabricated by Cotic’s big bike framebuilder Five Land Bikes up in Scotland, then finished in nearly indestructible Stormtrooper White Cerakote. It’s very much still a prototype DH bike for Frameworks Racing, so you can’t go out and buy your own just yet – and it might even change materials again before you can.

But built up with the Frameworks Racing Team kit, including new carbon stays, Fox Factory suspension, Reserve carbon wheels, Spank cockpits, Maxxis tires & the latest OChain R spider… the team is ready to hit the World Cup DH scene now. They’ve already started testing it against the alloy bikes to see how they compare. Stay tuned…