After acquiring the brand from founders Jake and Sam last fall, Project 321’s new owners are about to drop their first new product from the new Toronto-area manufacturing plant. The G3 hub builds on the rock solid design and nearly drag-free magnetic pawl system of the G2, but adds a more robust axle design and clever disc brake rotor mount that works with Centerlock and 6-bolt rotors.

The hub shell is machined from lightweight aluminum, like most hubs, and accepts a Centerlock rotor directly. But if you wanted to run 6-bolt rotors, you simply clip the stainless steel collet around the groove found behind the Centerlock section, then slide the adapter plate over that, like so:

They say all Centerlock hubs have a groove behind the toothed rotor interface (though it may not be in a standardized position, so these adapters may not work on other hub shells) that’s just part of the manufacturing design specificifactions…it allows for material clearing during machining.

The stainless steel collet has a split in it, allowing you to spread it slightly to slide it over the teeth and clip it into place. The adapter then slides over it and locks it into place.

They call it 6 Lock, and the benefit over standard 6-bolt hubs is that if you ever strip a thread or bolt, you can just replace the clip ring, leaving your expensive hub and already-built wheel perfectly intact. But because it’s stainless steel, and not aluminum, it’s unlikely you’ll strip the threads and it provides a stronger interface for the rotor bolts.

The result is a seamless appearance that’s also color-matched to your hub. Sure, other Centerlock-to-6 bolt adapters work fine, but they pretty much only come in black. But with Project 321’s new design…

…you could mix and match colors for the brake adapter and their end caps, letting you customize the look however you want. Hubs will ship with color-matched parts, others will be available separately.

But that’s not all that’s changed on the new G3 hubs.

The G2 used six pawls, which you could arrange in pairs of two or three depending on how strong of an engagement (think tandems and e-bikes) or how loud you wanted your hub to be.

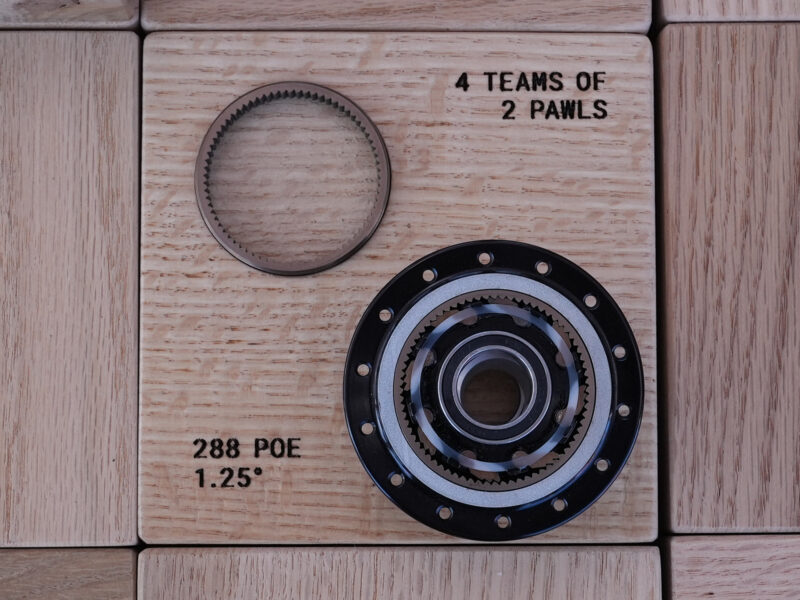

The G3 increases that to eight pawls, arranged in four sets of two to provide 288 points of engagement for a 1.25º rotation between clicks.

If we’ve learned anything about hubs over the years, it’s that really hard efforts can bend the axle slightly, and that it doesn’t take very much bend to start kinking things up and cause some pawls to lose a bit of engagement, which can lead to premature wear. So, with only two pawls engaging at a time, Project 321 needed to have a very robust system.

So they partnered with Stan’s to design a stronger axle that gets dual double-row bearings inside. One sides on the hubshell side, the other under the freehub body, both directly next to each other directly underneath the pawls and drive ring.

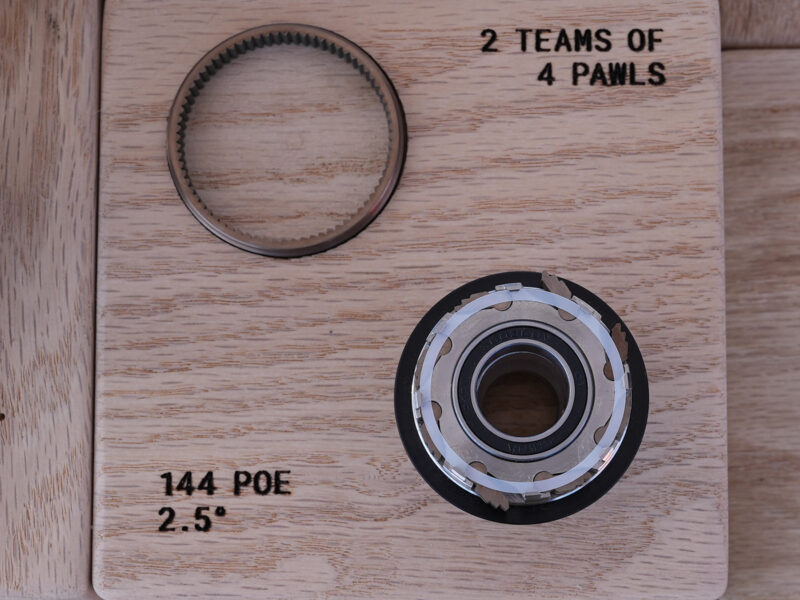

For e-bikes (and, presumably, tandems), they’re working on a prototype titanium freehub body that flips the numbers to two teams of four pawls engaging at any point. This reduces engagement slightly to 2.5º with 144 POE. It also adds an extra single-row bearing on the outboard drive side.

Target price is $650/set, likely available in late May or June in Boost and Superboost. Claimed weights are 155g (front) and 292g (rear) without the adapters, and 175g (front) and 312g (rear) with the 6 Lock parts onboard.

They’re looking at a complete clean sheet design for road and gravel hubs to make them a lot lighter, with distinct designs for each, but no word on when those might come out.