The possibilities that electronic shifting opens up are nearly limitless. As long as a button can be pressed somewhere, a signal can be sent and the derailleurs will move to shift the bike. SRAM has shown this with their BLIPS and newer MultiClics buttons.

Now, it looks like SRAM has combined a detachable wireless BLIP with their drop bar road hydraulic brake levers to create a button-free AXS eTap shifter. And they’re doing it by making the brake lever itself the shift paddle.

To be fair, Shimano’s been using the brake levers as part of their mechanical shifting design forever. It’s called STI, for Shimano Total Integration, and was introduced in 1990, combining indexed shifters with the brake levers for road bikes. They even tried it for a year on mountain bikes, but they weren’t popular.

SRAM’s take on it is a bit different. Instead of using a lateral movement of the brake lever to pull cable, it’s simply creating a lever that pushes a button. With their Double Tap system, it only needs to push one button per side to perfectly control both front and rear derailleurs, so it works. Here’s how…

How SRAM eTap Brake Levers can pivot

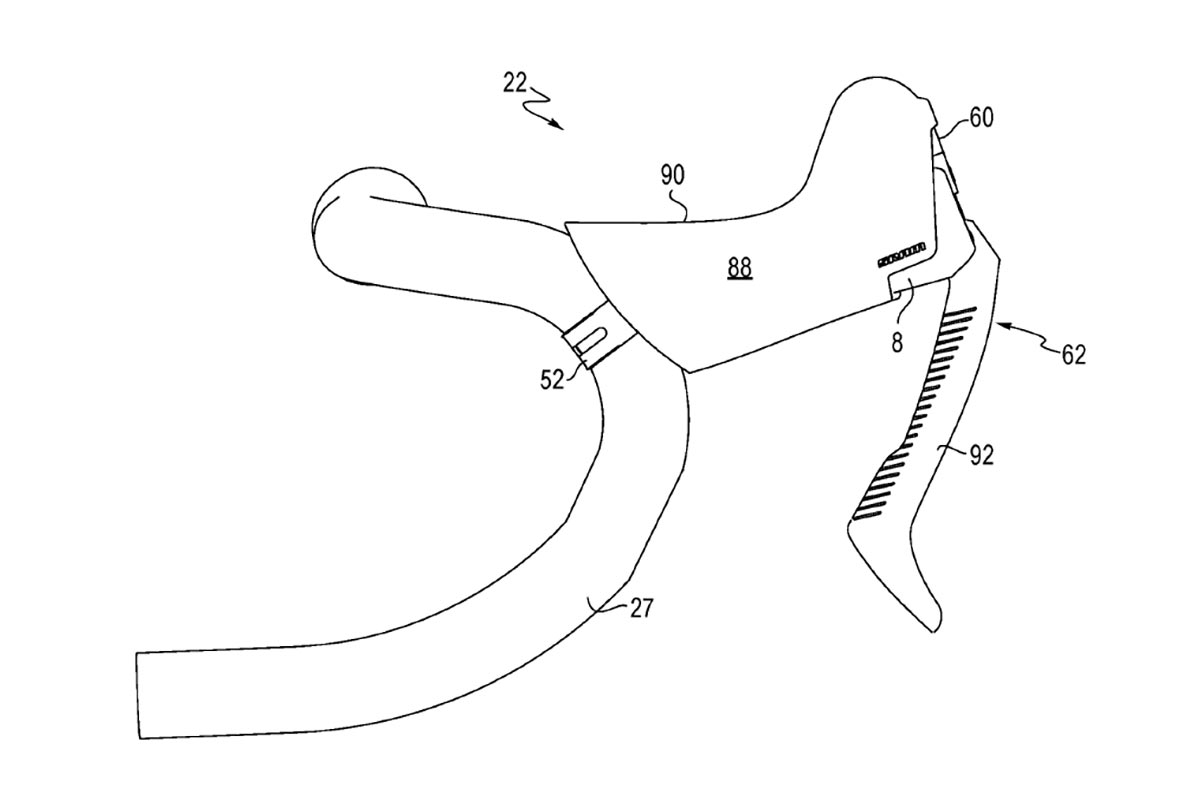

In this patent, SRAM explains that the brake lever is still attached to a main pivot (118, shown further below, with 94 being the axis of braking movement) that lets it pivot rearward as you grab it to activate the brakes. But that pivot point sits on a moveable member that pivots around a second axis (96) that is non-orthogonal (i.e. not perpendicular) to the braking pivot.

The drawings show multiple variations on the angle (96) at which the brake lever would move to create a shift…this lets SRAM angle the shifting movement however they want. It’s likely that getting the angle at which you push the brake lever sideways will be critical to having a crisp-shifting feel without also activating the brakes…and smooth braking feel without accidentally shifting.

In fact, the patent says the angle will likely be as severe as 45º to 60º so that as you pull the lever in the braking direction, “the shift-brake lever will be biased to pivot around the shift axis away from the shifting direction” to help prevent accidental shifts during braking.

If you’ve not ridden Shimano’s mechanical road levers, just know that getting distinct shifting and braking movements out of a brake lever is not only entirely possible, but also quite ergonomically functional.

It sounds simple, but being able to move the brake lever in relation to the master cylinder presents a problem. While they could simply position the entire master cylinder on the rotating portion, SRAM presents a better solution that keeps the braking parts firmly mounted inside the hood. Here’s how it works:

The brake lever (22) pushes a pushrod (152) into the plunger (140), which is what moves the brake fluid into the hose. The pushrod and plunger are connected with a ball joint (154), and that allows the brake lever to have some lateral movement without requiring the master cylinder to move.

OK, so how does it shift?

The shifting activation is really simple. The brake lever is attached is to a part (110) that extends upward, creating a longer lever (102). A small shift actuator nub (11) on that lever will press a button (189, below) on a bolt-on wireless transmitter unit (Figs. 14/15 below).

That unit appears to be powered by a standard coin cell battery and is likely nothing more than a re-shaped, self-powered BLIP.

The patent mentions that the position of the shift actuator is adjustable, letting them (and maybe you?) adjust the distance required to activate a shift. Regardless, the amount of brake lever movement required to initiate a shift should be very small.

The pairing/function button (194) and LED (192) relocate to the inside face of each shifter pod since there’s no longer a paddle for them to rest on.

What’s the benefit?

If you’ve ever grabbed a lot of brake, particularly on a rough gravel descent, and had the shift paddles (eTap or Di2) hit whatever fingers are still deathgripping the handlebar, and that paddle-to-finger contact limited how much braking force you could apply, then you’ll appreciate that there’s a lot more space now. This should allow deeper brake pulls. Or, at least, less encumbered braking on rough descents.

For smaller riders with shorter fingers, this should let them adjust the brake lever reach in further for easier braking, too.

SRAM’s patent also shows multiple heights for the forward bump on the hood, meaning riders could choose between different shifting module sizes if they wanted a smaller or larger protrusion on the front of the lever’s hood. Without wires, they’re simply bolted into place and easily swappable or replaceable.

Patent research assistance provided by Wheelbased.com. Check them out for deeper dives on some of these patents and more.