Carl Strong is legend in the custom frame building industry, known mostly for working with titanium of late. But about two years ago, he teamed up with started tinkering with carbon fiber to see what could be done with that material in a small batch, made-in-the-USA environment. The first model was the 2018 Mark I disc brake road bike. For 2019, it’s replaced with The Lead Out, which incorporates everything they’ve learned during that first year to offer a smoother, lighter bike.

“The primary improvements are in the layup, and it’s about 180-200g lighter depending on frame size,” says Strong. “We took about 20% of the material off of the main layups.”

Incremental process improvements also came about with the hiring of Eric Rolf from Alliance Bicycles. Strong originally mentored Rolf before Rolf went out and created his own brand, and now he’s come back to work directly with Strong and the team at Pursuit.

The molds are the same as the original Mark 1 model, so it really is just layup and material changes. Handling should be similar, and stiffness will be similar, too. So, was the original one overbuilt?

Claimed frame weight for The Lead Out is between 900-950g for a 56.5 size, fully painted. The Mark 1 originally had a similar claimed weight, but actual production frames came in closer to 1100g once painted and ready to ship. Strong says, for this model, they may add a little more material here and there depending on the customer. He says that weight is only the third priority, behind ride quality and durability. He says it’s not necessarily a challenge to make a 700g frame anymore, but it is a challenge to make one that rides well and won’t disintegrate on impact. He says complete bikes are coming in between 15 and 16 pounds.

As with the Mark 1, they’re only making 35 bikes for 2019. They’ll make them in four sizes (54.5, 55.5, 56.5 and 57.5), but if they end up selling all of them out extremely early this year, they might do a second run later in 2019. Why so few? Because each one takes about 60 hours to make, and they want to keep their team small and build them at a comfortable pace that keeps them focused on quality.

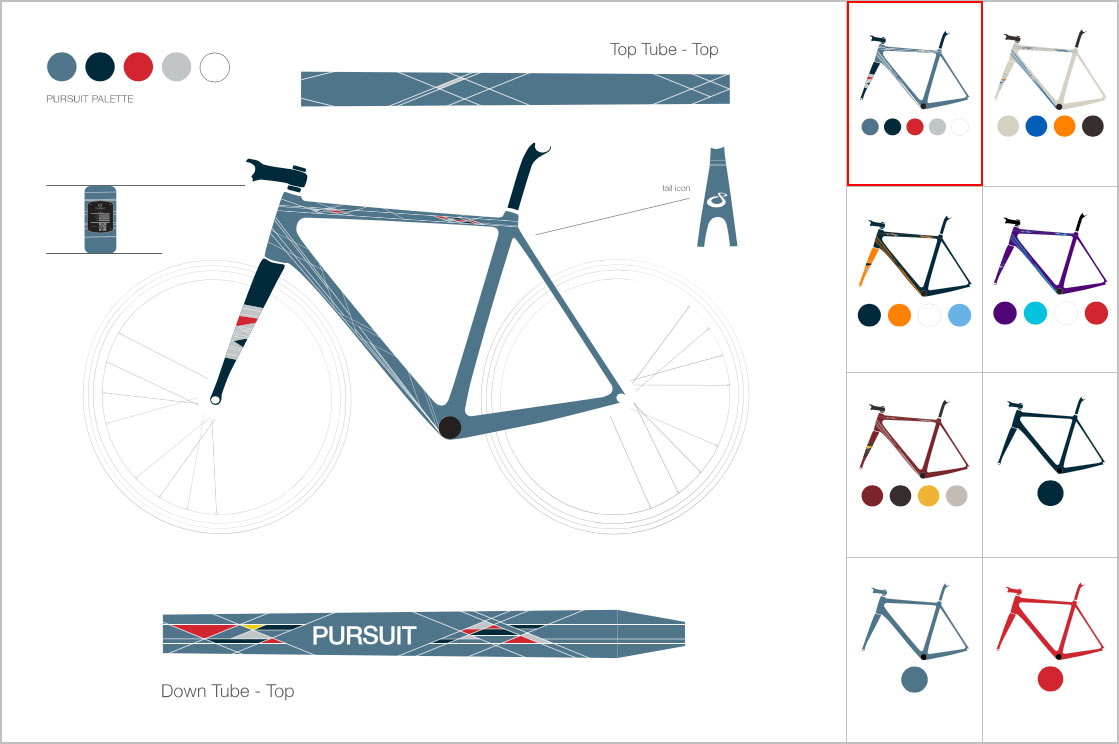

A few are already sold, price ranges from $10,000 to $13,870 depending on build options. They’re only sold as complete bikes, and really only with top-level groups and wheels from SRAM, Shimano, Campagnolo, and Chris King/HED or ENVE wheels. There are five design color options and three solid colors. The graphics are actually outlined rectangles, but as they overlapped and some were filled in, the design reminded them of a top-down helicopter view of a peloton sprinting toward the finish. The yellow triangle would be the leader’s jersey, drafting their lead out crew…and that’s how they came up with the name for this year’s bike.