Norwegian tire company ReTyre has been on our radar for several years, with their unique approach to tire construction. First, it was zip-on tires. Now it is a completely new continuous injection-molded construction from pre- and post-consumer materials that create tthe world’s first ‘Carbon Neutral’ bicycle tires.

ReTyre World’s First Carbon-Neutral bicycle tires

Oslo, Norway is home to reTyre, a company that has recently shifted to mass-producing sustainable tires in 2022. At this year’s Eurobike, they’ve announced the “world’s first carbon-neutral tire”, made of a mix of recycled and reclaimed materials combined with a by-product of restoring aquatic ecosystems – all in an effort to use cutting-edge manufacturing technology to reduce emissions from bicycle tire production.

ReTyre claims that the tire is crafted from groundbreaking materials, and the innovative concept marks a monumental step in sustainable tire production.

A Revolution In Tire Manufacturing

The first step is the raw materials that make up the new tire – but it’s a unique construction that makes it all work. Instead of a conventional fabric casing wrapped around a mold and then overwrapped with one natural rubber tread at a time, ReTyre continuously molds a giant spool of flat tire.

The casing feeds through a mold, where a thermoplastic mixture with a consistency and durometer somewhere between rubber and TPU is injection molded directly onto the casing. Then the casing rolls a bit further, and the next set of tread is co-molded on. The result is up to 1-1.5m of tread molded at a time, with relatively smooth seams or transitions from one to the next, right out of the mold.

The tire is then rolled onto a giant spool.

Only later is it cut to length for the desired tire diameter, and the casing and tread are bonded into a loop to form a single tire. This method is said to further reduce emissions from the shipping and distribution process. So while the spool of tire is manufactured in Norway, ReTyre can finish tire manufacturing with more simple tooling in the local market.

Unique recycled and reclaimed ingredients

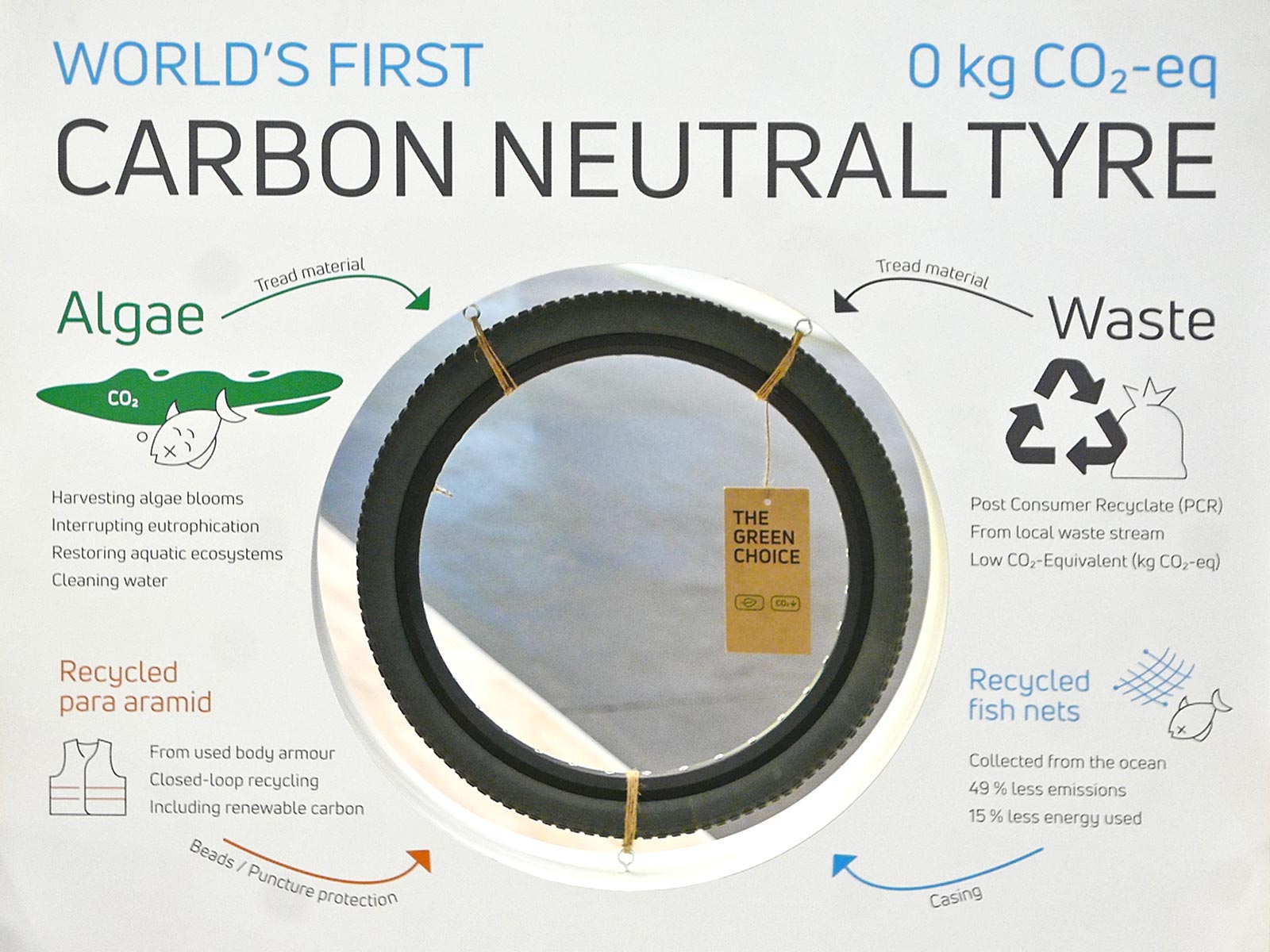

ReTyre’s Carbon-neutral tire incorporates several unique materials in its construction, each chosen for its ability to minimize environmental impact:

The ReTyre tread includes algae harvested from out-of-control blooms that were damaging the local ecosystem. By removing the problematic algae, it halts the eutrophication process that chokes out native fish, disrupts natural ecosystems, and emits methane into the atmosphere.

That algae is mixed with post-consumer recycled plastics to create the tread. Interestingly, it seems the algae binder + plastics recipe is more flexible on what materials can be added.

Recycled casing & protection, too

Utilized from used body armor in a closed-loop recycling process, ReTyre incorporates renewable carbon in recycled para-aramid fibers back into the tire beads and its puncture protection layers. And then the fibers of the casing itself are said to be woven from used fishing nets at the end of their life. Recycling the nets is said to reduce emissions by 49% and energy use by 15% vs. using virgin nylon materials.

The Path to Carbon Neutrality

The person who is leading the Carbon Neutral Tire Project at ReTyre is Froiedemann Ohse. He elaborates on the meticulous process that goes into achieving carbon neutrality. “The product carbon footprint of this tire is based on our third-party verified LCA, including the end-of-life, which is how we measure all our products. Our production and transportation processes are optimized to be close to zero emissions“.

Ohse continues, “End-of-life is reduced to almost zero due to the recycling of the tires. The algae used in the tire has a negative CO2 equivalent, balancing any remaining emissions to achieve a net-zero impact. In this way, we have a carbon-neutral product without using any of the well-known shortcuts, such as carbon quotas, subsidies, or other non-product related contributions.”

A Global Effort in ReTyre Carbon-Neutral tires

ReTyre collaborates with global suppliers to responsibly source their materials. For instance, the algae used in the process is harvested from lakes and oceans worldwide and is supported by the UN Ecosystem Restoration Program.

Unique Materials + Manufacturing Possibilities

Using its 100% sustainable product portfolio, ReTyre can offer brands a wide range of sustainable tires without compromising quality. By using bio-based and 100% renewable materials that have never been used before, ReTyre significantly reduces emissions and produces fully reusable tires. They can even make the rubber or main casing structure in a wide range of colors.

This approach reduces GHG emissions by up to 82% compared to conventional tires. Friedmann Ohse also said, “This carbon-neutral tire is at a concept stage and it is a result of continuous innovation that shows what our unique manufacturing is capable of“.

Eurobike’s ReTyre Carbon-Neutral tire lineup debut

Within the concept of their groundbreaking carbon-neutral tire concept, ReTyre showed the wide range of sustainable products possible with this new construction at Eurobike. That includes a new City Range tires designed for the urban cyclist and Children’s Range of tires meant for low-cost OEM kids’ bikes.