More so than any year I remember, Sacramento 2016 was an exceptional show for new talent. There was not a single dud in the bunch. Everyone came with something to set themselves apart from the pack through caliber of finish, concept, process, or all of the above. Plus, the bikes were so diverse in category and fabrication method that it would have been impossible for me to pick a single favorite. Fortunately, NAHBS has personalities on hand who are happy to do just that. When the dust had cleared, Kevin Fickling of Cryptic Cycles was named Best New Builder out of the talented field, with some suggesting that he should have been in the running for best carbon bike, overall.

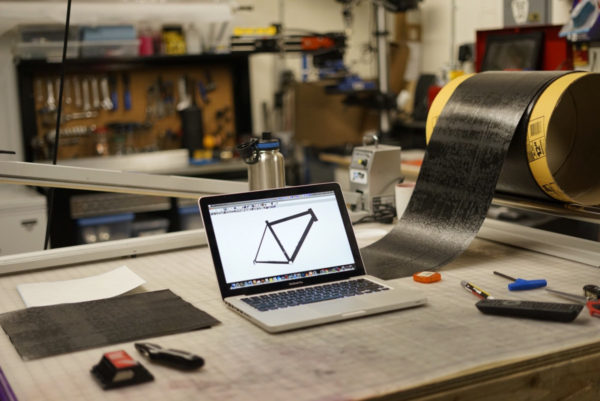

His full carbon road bike was exceptionally finished. Tubing was made in-house and dropouts as well as cable stops and guides were constructed and machined by Kevin. For me, however, the fun was in the materials. Kevin also utilized Boron fibers as well as glass microbeads to keep the weight of the frame below 700g. Given that this impressive performance came from a builder only in his first year, we’re looking forward to what Kevin will be bringing to Salt Lake City a year on.

BIKERUMOR: You had your NAHBS debut last year to great acclaim. It was even suggested that you deserved Best Carbon Bike, overall… but you had to settle for best new builder instead. What effect has winning had on your general direction? On your style?

KEVIN: I was so grateful to receive the best new builder award last year! So many other new builders brought out amazing bikes made for every different riding style. Winning the award has made me work hard to bring something new to the show this year. I really want to show bikes with a noticeable improvement in craftsmanship as well as improved manufacturing techniques. Attending the show last year and getting to see some of the frames in person from builders I look up to was a great experience that really motivated me.

BIKERUMOR: Your frame last year, you had several interesting tricks up your sleeve. You used glass microbeads to bulk up parts of the frame without adding weight. You added boron fibres to aspects of your matrix. Have you continued to up your material game?

KEVIN: Materials are always something that I’m looking into. Building in the US offers an advantage because some of the material is not available to overseas manufacturing facilities. This year I have been experimenting with a wide range of new materials. I’m most excited about an epoxy adhesive layer introduced to the frames. Before carbon is over wrapped to reinforce the junctions, a layer of structural adhesive is added. This helps to increase the shear strength, toughness of the cured laminate and fatigue resistance.

BIKERUMOR: How have you evolved over the past year?

KEVIN: My bikes have evolved a lot over the last year. I have introduced new techniques throughout the frame working with Dave Bohm at Bohemian bikes. We bounce ideas off each other weekly and it really helps to have someone with the design ability, real world experience and downright craftsmanship like he has. The top tube, down tube, brake bridge and chain stays are now molded to create a perfect finish inside and out as well as giving the ability to change layup on the fly. I have also introduced an option where the bike is completely painted by hand using a brush and custom mixed colors. All the original art is done by Katie Hopkins and can take upwards of 30 hours per frame.

BIKERUMOR: How has your emphasis changed?

KEVIN: My emphasis has been on improving the small details of the frames. The proportions of the tubing and the way everything flows together is something thats really important to me.

BIKERUMOR: If you could only listen to a playlist of five songs while you build, what would those five songs be?

KEVIN: The Police- “Spirits in the material world”

Pete Philly & Perquisite- “Lazy”

Tribal seeds- “Dawn of Time”

Led Zeppelin- “All My Love”

Pink Floyd- “Wish You Were Here”

BIKERUMOR: What framebuilder (that you do not know personally) do you admire and why do you admire them?

KEVIN: I really admire Tom at Demon. I read the interview you did with him and man I want one of those bikes. What a cool attitude and story he has. When he first started out and people were being negative on him he just kept pushing and did his thing. It seems to be really paying off for him now.

BIKERUMOR: Which builder would you most like to collaborate with on a project? What would that project be?

KEVIN: I would love to collaborate with Dave @ Bohemian to create a carbon/steel lugged frame. Something with those beautiful hand carved lugs and crazy attention to detail. Taking another class with him to learn steel techniques is something I want to do within the next year. I think its important to learn as much as you can and not limit your knowledge to one material.

BIKERUMOR: What is your main bike at the moment? What is that your main ride?

KEVIN: My main bike is my take on a classic road race bike. Aggressive geometry, lightweight and simple looks. I typically spend most my time on the road and for me a bike with classic lines and modern technology is what I’m drawn to.

BIKERUMOR: What do you put on your hotdog?

KEVIN: I’m pretty boring when it comes to hot dogs… just Ketchup for me.

Looking for more information about NAHBS? Check out HandmadeBicycleShow.com