Every year at the North American Handmade Bike Show we highlight the framebuilders bringing the deep custom heat to the show floor. What we don’t often talk about are the many other brands that add the fire. A bicycle is more than its frame, after all; NAHBS is a bicycle show.

This very topic came up on a recent call with Paul Component Engineering Liaison to the Stars, “California” Travis (who, for full disclosure, I have been scheming with for the past six months on parts for my Peacock Groove Prince Tribute bike). A month or so before each NAHBS, PAUL puts out a call to builders to understand what their needs might be for the show, fishing for cool collaborative opportunities to take deep custom, even deeper.

This year, the company has collaborated with four builders to bring custom bike projects to the next level via custom colors, finishes, and machining. I hit up the builders of each of these bikes for comments on their builds, as well as a few sneak peek photos…

Before diving into this custom madness, it’s worth saying that it isn’t every day that PAUL does custom product. Currently, product is available in silver or black, with some parts in high-polish and purple. As Travis told us, “There is the part of us that wants to sell a lot of bike parts so we can make money so we can eat, and then there is the part of us, like me and Paul and you and everybody else, that does stuff for the bike industry just out of passion. Like, Sklar wants some dope-ass brakes? Let’s get him some dope-ass brakes. He makes sick bikes. He’s a nice guy.”

W. H. Bradford, Yeti Ultimate Homage

From the mouth of builder Brad Hodges:

“What’s the best way to put this – it’s a modern version of an original Yeti Ultimate. It’s an homage to the original bike that John Parker and Frank the Welder built. It’s one of, if not the most bad ass steel frames ever made in my personal opinion, built in an era before suspension and rocket science tech. This was the pinnacle of hardtail frames at that time. Last year, I built a modern Klunker that was pretty well received and well what was I going to bring this year but a bike from the 80’s.

“I’ll be honest, I thought it was going to be a lot easier to build than it was. But I didn’t start framebuilding because it was easy. Building “throwback” bikes like this, while incorporating modern geometry and standards can be tough, while still retaining the original design influences. On this bike, that’s the bent down tube and the correct angle for the love tube,’ which is the tube that runs between the down tube and seat tube that give the visual look of one single flat tube with an extension off the bottom.

“I also had to re-create the iconic Yeti Ovalized top tube. Which required the help of Jeff from Monkey Likes Shiny to machined a one off die to form the top tube. I came with the numbers, and Jeff made the die while we were hanging out at his place one afternoon. I guess I’m lucky to have friends in my life who are willing and capable of taking my bat-shit crazy ideas and helping me make them a reality.

“The loop stays were another one where I had to call in some help. Cameron Falconer is quite the skilled tube bender and when it came time to make a loop tail, I knew he was the guy to call. He got the loops bent to my drawings and it was up me after that to make the rest work.

“I’ve been a huge Paul Component nut since I was a kid – like, I was a PAUL GROM back in the late 90’s. I have a Bontrager Racelite with a full PAUL vintage group. Last year at NAHBS I was talking to Paul [Price] saying I wanted to build a new bike using his parts. He said, “Let’s make it happen.” After some thought I gravitated toward this project. A lot of that influence was from the look of his new Set It and Forget It Quick Release Thru Axles and how they reminded me of the ONZA quick releases used on the old Yeti’s. That’s what led to me thinking about doing a Modern Ultimate with his parts.”

According to Travis, parts had to be sent to a special anodizer to get just the right turquoise to fit with a properly Yeti-themed build. Also, the rear axle length is custom to this single bike, so the CNC machine had to be reprogrammed to accomplish this single build.

Sklar Handmade Bikes

From Adam Sklar:

“I like going all out on color schemes, and I always love polished parts. When this customer requested PAUL Brakes, I called up Travis at PAUL who was happy to make it happen.”

“It’s cool to have connections with the people making your stuff. They’re not just people I buy parts from, but they’re folks I get to see around the country at bike races and events, and that’s pretty cool.”

Retrotec

From Curtis Inglis:

“I am building myself a 29+ bike around the Chris King 40th anniversary kit. I thought it would be nice to tie in a few other company’s stuff to the build. Paul Comp and White industries were game, so we had a few small parts done in the olive green as accents to the King bits.”

Peacock Groove

This is why I was on the phone with PAUL to begin with. While there will be a lot of custom polished and anodized PAUL Component parts on my personal Peacock Groove Prince Tribute bike, there is one significant last piece left to go.

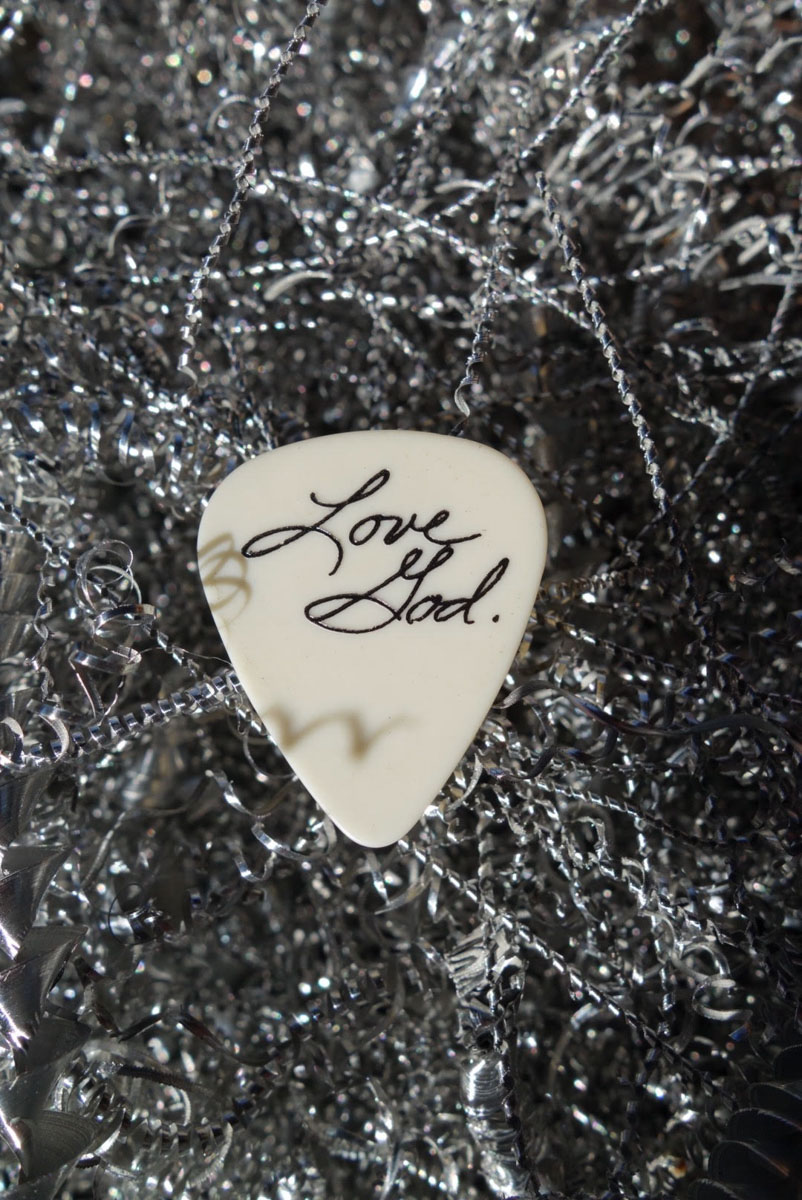

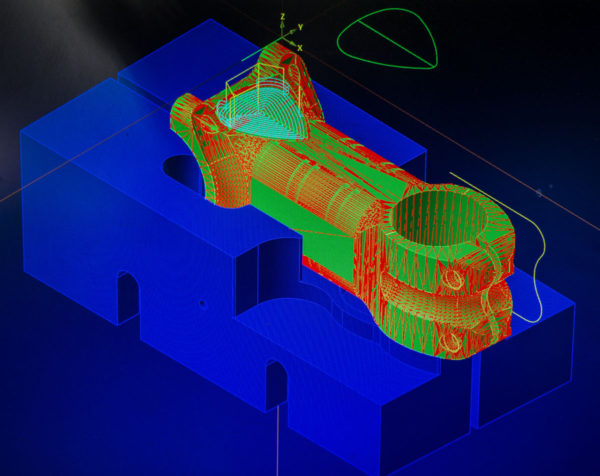

See, when Erik Noren started building this bike, a musician friend sent me one of Prince’s picks to incorporate into it. How? I had no idea. So I asked PAUL to figure it out.

I actually have no idea what the final product will look like, but Travis sent me this photo for this piece. I won’t see it until everyone else does.

Getting stoked and want to learn more about the show? Check out HandmadeBicycleShow.com