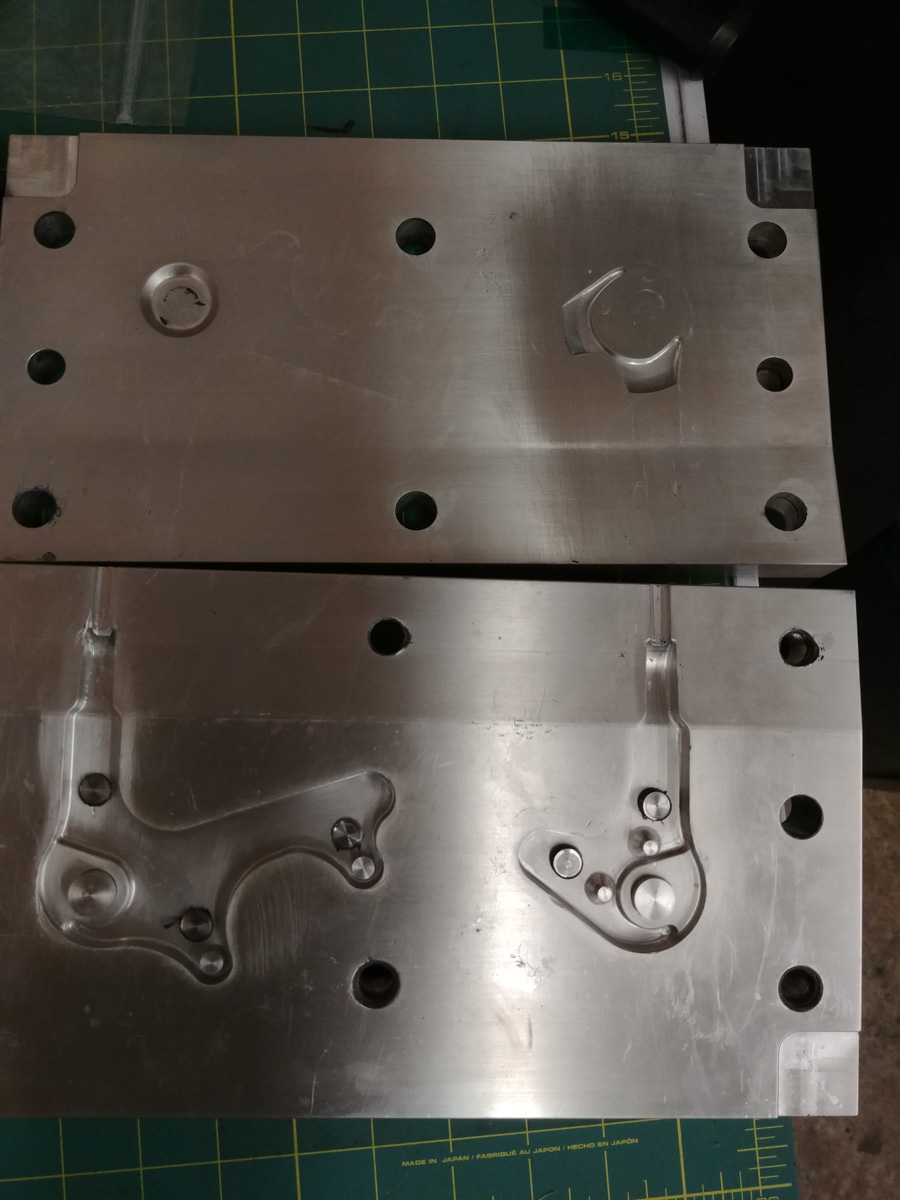

With one foot squarely in the world of top level cyclocross racing (Chris coaches some of the fastest athletes in the world when he’s not building frames, no big deal), Chris McGovern’s personal focus is solidly about performance. Dissatisfied with the level of existing infrastructure for custom carbon frame builders, Chris has been hard at work developing his own bag of tricks. At NAHBS in Salt Lake, Chris rolled up with a bike featuring the fruit of his first major tooling investment: a special high clearance chain stay system. This year, as seen by the nifty dropout system he leaked on social media a few weeks ago, Chris has gone even deeper.

BIKERUMOR: What are you bringing to NAHBS this year that you’re excited about?

CHRIS: I am only bringing one bike to NAHBS this year. I have been essentially working on this bike for over a year. Developing all the bits, tubes and tooling… and it is still coming down to the wire. It’s a dual wheel size gravel bike, we call it “Splice.”

Seems like a lot of folks are getting on this style bike and just copying, for the most part the OPEN bike. I wanted to solve the tire/chain ring problem differently and I think we did. I also have made some “in the wild” observations of this style bike… fit and handling to be specific, that I think I have addressed with the geometry. These, of course are fully custom as well.

BIKERUMOR: What are your current challenges in adopting and implementing new standards?

CHRIS: It seems to me that most of the “new standards” are usually rooted in marketing or the greatest new thing. When a lot of these “new” things are one season and done. I am all about trying new things, but when the hype is out in front of the substance of the “new” it can be challenging. As a carbon builder, anything new requires tooling, development, testing, refinement, 1st article and a working part and process. It is super expensive. So I am often leery of “new” standards. Flat Mount brakes for example, I really don’t see the purpose, but you have to offer it… for now.

BIKERUMOR: What new or upcoming standards are you excited about?

CHRIS: Fuck! No! Stop it. Haha, this isnt new, but I am actually glad 142×12 thru axle exists. From a building point of view more than a performance perspective

BIKERUMOR: What type of bike have your customers requested most in the past 12 months?

CHRIS: Most common bike I get asked for is a cross/gravel bike.

BIKERUMOR: What is the next bike you’re building for yourself?

CHRIS: Most likely a cross bike. I have developed some chain stays, well, two options of chain stays, that will accommodate a 700x45c tire and two chain rings. Which are my design default for this category – it doesn’t exist for Carbon builders. [You] can’t bend or dimple that shit. It’s different than the “Splice” bike chain stay. The “Splice” bike is more of a Rowdy Gravel/Adventure bike.

BIKERUMOR: …and if someone else were building your next bike for you, which builder (of all time) would you choose and why? What would it be?

CHRIS: Ooooh, that is tough. I would normally say something Ti, but I have dreams about a fillet brazed steel cross bike. I would be calling Darrell Williams at Thrive for that one. I just love the looks of his work. Darrell, want to give me a brazing lesson? It’s been awhile! I know he is too busy to build me a bike.

BIKERUMOR: What is your “blank check” bike?

CHRIS: Blank check bike, I would ask Steve Rex to collaborate with me (let me help a little) with a steel “lugged” bike with some carbon tubes. I know Steve has done this type of bike and would not need my help… so that would be the expensive part – letting me help!

BIKERUMOR: If you could exist in another period of framebuilding, what would it be and why?

CHRIS: 1980-1990 American frame builders. In ’85 I was bored with BMX as my main mode of transport and got into road bikes… Nevada City had several frame builders who were just cutting edge in my opinion. Ron Miller (Boogie Bike) was doing a lot of things no one was doing and it was just rad. Every road bike at that time was essentially a lugged road bike. TIG welding and brazing, flaring tubes were not the norm… these things really caught my attention. Mountain Goat Cycles, Otis Guy, Billy Kostrikin – these guys all lived within three hours of me and were building such rad stuff. I wanted an American bike way more than an Italian bike (I had a Geurciotti at the time, and after that a Rolland Della Santa), I am rambling…

As to why? I feel like these builders were the builders who lit the torch for hand built bikes as I see it.

BIKERUMOR: If you had to stop building in your current material, what new material would you choose and why?

CHRIS: Steel. I would build steel bikes. I want every one to have a hand built bike and I feel like steel is the most adaptable and affordable material. Basically I think you could make any type of bike with steel if you are a good enough problem solver and it wouldn’t be as expensive as say, carbon.

BIKERUMOR: If your shop was burning down, what one or two tools would you grab to save? Why would you save them?

CHRIS: In my current state of building I would save my vacuum pump, it’s the most expensive thing I have out there and I doubt I could afford to replace it. Boring I know. It is also probably the most critical piece of equipment in my process.

“Meh-” in fact if my shop was on fire, I would push my down draft table into the middle of the burn… thing is just in my way and doesn’t work very well!

The North American Handmade Bike Show will take place from February 16th to 18th in Hartford, CT. For more information, visit the NAHBS website.