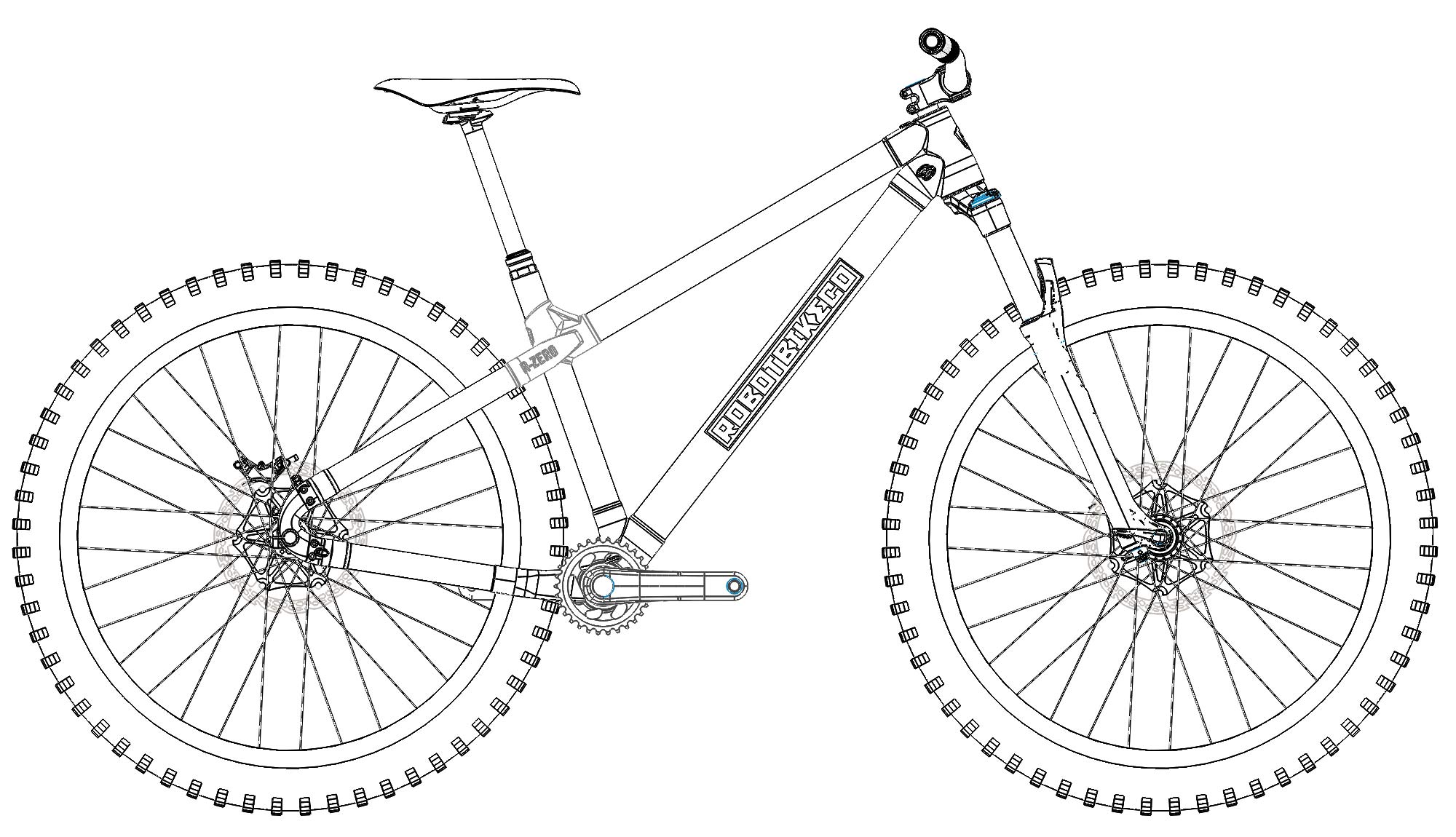

Robot Bike is taking their unique 3D printed titanium lugs & carbon tubes, and developing a new aggressive trail bike platform. Offering more customization than ever before, the R-Zero Platform is about erasing design limitations. Using the same tech refined on their custom enduro and trail mountain bikes, they’ll build a trail hardtail where you pick whatever wheel size, hub standards, and geometry that you want.

R-Zero Platform – custom 3D printed ti & carbon trail bike

Robot are in the final stages, developing & testing their newest R-Zero Platform. Called a ‘Platform’, the basic principle is that with their “parametric CAD model and construction method” they can fabricate a hardtail that is truly one-off custom for every single buyer.

You pick the wheel size that you want (even 26″ they say. How about 24″?) You pick the hub & axle you want. You decide the geometry that is right for you – super slack, or super long? Don’t worry, Robot will do whatever custom bike fitting you need too.

Then they enter all the details in their design software, and a unique-to-you lugset is created. Take that over to the titanium sintering/Selective Laser Melting machine (the robot), and it 3D prints your lugs. With their double lap joints, Robot securely slides in your cut to size carbon frame tubes, and the result is a trail ready hardtail mountain bike to tame whatever singletrack you can find.

First Prototype & tech details

Robot sent us these dark teaser photos of the first complete prototype, which belongs to one of their founders. The R-Zero Platform is Andy’s baby, so it makes sense that he gets the first bike. His R-Zero is a 29er with a 130mm fork, a slack 66° head angle, 74° seattube, 435mm frame reach, tight 420mm long chainstays, and 65mm of bottom bracket drop.

As for other details, the bike does feature a standard threaded bottom bracket, and a stealth dropper post. It gets some pretty trick downtube internal cable routing too, that keeps shift wires inside all the way to the possibly interchangeable dropouts, but exits the rear brake out of the top of the BB/chainstay yoke.

The R-Zeros are developed as an aggressive trail bike, so even though geometry is flexible, expect frame weight to come in just under the 2kg/4.4lb level.

Get the compliant ride of a titanium hardtail, with carbon hardtail pedaling efficiency. Pricing is still up in the air, as is the official launch date. (The full-suspension frames are around £3900 with VAT.) If you feel like you can’t wait, send them an email to register interest in a pre-order.

Over on social media, Robot Bike is teasing the R-Zero under the hashtag #bespoke. They are confirmed as an exhibitor at Bespoke Bristol starting April 20, so it will most surely be on show then.