3D printing has had a place in the bike industry for many years now. Lately though, it seems to have really exploded. Part of that is how much more accessible additive manufacturing is now, with Ender 3s going for $99 at Microcenter (with a coupon). On the other side of things, 3D printing technology is rapidly improving making it easier than ever to create rapid prototypes of complex shapes.

Taking advantage of the newer super-fast Bambu X1C printer, OutsideBrendan was at the Marin Cycles booth printing on-site. Those attending the show could snag one of his BananAdapters while checking out some of his creative chainring designs or a Lego saddle?

Selle Italia

Speaking of saddles, 3D printing is becoming a lot more common to create performance-oriented models. The use of 3D printing allows companies like Selle Italia to build up the padding using lattice construction that can be progressively tuned – meaning the back of the saddle can be made more firm than the front when you need more cushion.

Above is the new Novus Evo saddle which is 3D printed using a Carbon L1 3D printer – the same printer which is being used for other products like the Specialized Mirror saddles and Adidas 4D midsoles. The covers are printed two at a time and take a few hours to complete, and are then glued to the base. The Novus Evo uses its own pattern for the cover, and isn’t available for sale just yet. When it is, it will be offered in one size with carbon or ti rails and is fully made in Italy.

Abbey Bike Tools

Known for their incredibly precise machining, Abbey Bike Tools was also showing off some 3D-printed parts. If you own a Crombie tool, chain whip, HAG, or Decade chain tool and you’d like a 3D-printed tool hanger for pegboard, you’re in luck (click link for each tool for the corresponding holder). Abbey will be offering these files for free, so you can download them and print them at home on your own printer. They’re also taking feedback on the designs if you think there is a way to improve them.

Abbey is also selling their new PreHag tool which is also 3D-Printed. What’s a PreHag? Think of it as a precursor tool to use of the HAG (Hanger Alignment Guage). The PreHag fits onto the largest cassette cog, and acts as a visual gauge to see if the derailleur cage is roughly in parallel with the cassette. Essentially it’s a visual aid that will let you know if you need to bust out the HAG for some hanger alignment (assuming you’re still running a traditional derailleur hanger).

Elevation Wheel Company

Chris Murray of Elevation Wheel Company has been producing tools for a while now, including a number of 3D printed items like their nipple shuffle box. The time-saving box allows you to dump nipples in for a wheel build, give it a shake, and they all end up pointing down so you can load them up on a nipple lacing tool and build your wheel. They even had miniature versions made into keychains at the show.

Other 3D printed items include a hub press adapter for the wheel spoke stressor, wrenches for their spoke tension calibration tool, and replacement jaw pads for repair stands.

Chris also put the printer to work printing out display items for Twisted Spoke CBD who was sharing the booth.

Mend It Kits

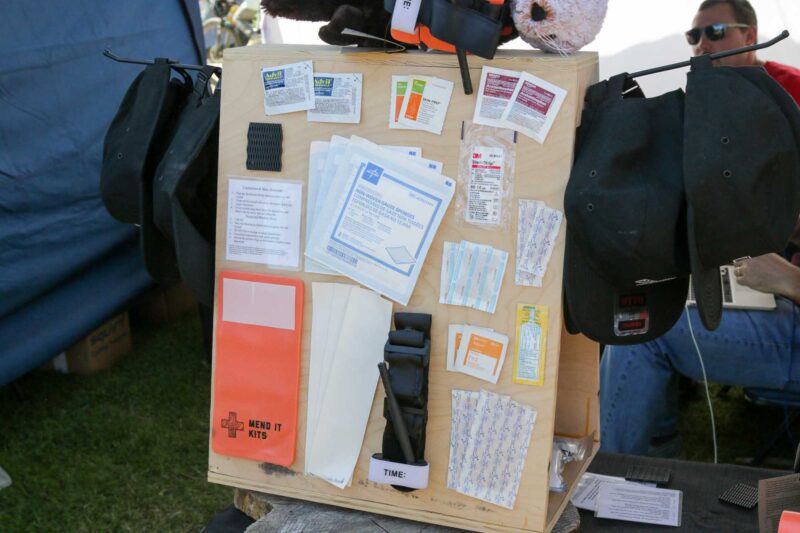

Moving from tools for your bike to tools for your body, Mend It Kits are an interesting take on the first aid kit that you strap to your bike. Everything shown on the board is included with the kit, including…

…these 3D-printed finger splints. The printed design makes them flexible in one direction, but not the other. Place it around your finger, trim to size if needed, and tape it up.

KAV Helmets

When it comes to 3D-printed helmets, we’ve been following along with the KAV development for a few years now. Every time we see them, the helmets feature impressive improvements, with quick design changes one of the main benefits of 3D-printing. Not only is KAV preparing to launch different color helmets later this year, but the helmet itself has seen updates including a new brow-liner sweat-management pad. You’ll also find larger front vents for better airflow and improved spring-loaded pads with more comfortable surface materials.

KAV will begin to offer solid color helmets in Q3 of 2023, followed by their custom Color Exploration Program which will allow riders to select different color panels.

SRAM Blackbox

We don’t have much info on this, but these appear to be prototype SRAM brakes with 3D-printed Blackbox shields. Are the shields there to hide something from view? Are they to protect the brake, or the rider from the brake? Perhaps some sort of cooling device?

Whatever the case, they were on Kyle Strait’s Vitus Dominer DH bike which also had some prototype tires from Kenda.

Neuhaus Metal Works

From components to frame components, the relatively new custom bike brand Neuhaus Metal Works is using 3D printing to create ‘lugs’ and other frame parts for their steel and titanium builds.

The Neuhaus frames use four different 3D-printed pieces on the complete build. The seat post cluster is printed so it wraps around the seat tube allowing for better and stronger welds and better frame alignment. The chainstay yoke is printed to provide the most tire clearance and weld surface to the bottom bracket. There’s also a water bottle bracket that allows you to use a full-size water bottle bolt without interfering with the dropper post insertion. Finally, the dropper port plug is printed with an insert that holds the cable in place and prevents it from rattling.

Each bike is handmade by Nick Neuhaus in Marin, California, and is available as the Hummingbird downcountry model or the Solstice 29 aggressive trail bike.

Rise Bikes

Also using 3D printed titanium is the Grizzly fat bike from Rise Bikes. This beauty uses a 3D-printed head tube, dropouts, and chainstay yoke made from 6Al/4V Titanium by Selective Laser Melting. The 3d printed chainstay yoke allows for 26 x 4.8″ or 27.5 x 4.3″ tires on 85mm rims while keeping chainstay length to an impressive 434mm.

Sage Cycles

Sage Cycles is also using 3D printing to develop a new dropout that is shaped to look like the Tron Lightcycles’ wheels, where the axle looks like the hub from the original movie, but the shape is from the sequel. The dropouts are designed specifically for the Robert Axle Project thru axle.

Revel Bikes

I lost most of my images for the Revel Rodeo, so I had Adam Miller send me a snap from his booth. This roundup wouldn’t be complete without the prototype Revel Rodeo – a 3D-printed thermoplastic downhill mountain bike. Rather than just printing a few components of the frame, the Rodeo frame is printed with the main triangle split into two halves, and then bonded together. Simply a design exercise for now, the Rodeo could point toward the future of 3D-printed manufacturing in the bike industry.

Silca

We’ve seen a lot of 3D-printed products from Silca, and this chainstay above is simply a proof of concept. Are many (any?) brand 3D printing an entire chainstay assembly? No, but you could…

Hunt Wheels

A lot of these products are actual production items that have been 3D printed, but additive manufacturing is just as, if not more useful for rapid prototyping. Here, Hunt shows us some rim sections from an upcoming wheel along with a jig they designed to help test spoke pull-through strength of the rims.

Outbound Lighting

Along those same lines, Outbound Lighting has been using its new Forum Labs Fuse SLS printer to develop its next headlight. Most of the hobbyist printers including the Bambu X1C above use FDM (Fused Deposition Modeling) printers, but some like the one Outbound is using rely on SLS (Selective Laser Sintering). These printers can create incredibly precise and intricate models with very little post-processing.

The light above is a new MTB light coming this fall, and all the printed pieces could be snapped together to create the final form.