Over the weekend at CX Worlds in Tábor, we spotted a small CeramicSpeed crew meeting with several different teams to talk ceramic bearings and low-friction lubrication AND showing off a next-gen prototype OSPW system. Designed for both road & cyclocross, this new version of their Shimano oversized pulley wheel system upgrade gets solid pulleys and ADR tech inherited from MTB for smoother, longer running…

Prototype updated CeramicSpeed OSPW for Shimano Di2

We’re always psyched to find prototypes in the pro pits. Whether hidden in plain view like the new Campy power meter. Or slightly more incognito like this classic black tape covered derailleur cage. Here, fitted to a Cube Cross Race bike from Team Charles Liégeois, the cyclocross racing offshoot of Intermarché–Wanty. And CeramicSpeed was roaming the pits checking in with mechanics from several top riders. We later caught up with the CeramicSpeed crew. And they said they were checking-in with existing sponsored riders, meeting with potential new partners, and even quietly handing over some product to unsponsored teams who use CeramicSpeed gear without sharing that publicly.

So, what’s new in the OSPW department?

The CeramicSpeed prototype that we spotted is an updated version of their long-running Over-Sized Pulley Wheel (OSPW) upgrade for Shimano rear derailleurs. In fact looking back, it’s been almost a decade since we first spotting the CeramicSpeed OSPW solution for Shimano. And outside of a few changes in pulley teeth numbers, that core curvy carbon cage upgrade hasn’t changed much since.

Now, that appears set to change with a new angular design.

CeramicSpeed suggests that their next-gen OSPW gets more angular aesthetics. That better fits with the shaping of modern road bike groupsets. Even under a strip of black electrical tape, this prototype certainly looks like a better fit with the latest Shimano Dura-Ace Di2 rear derailleur, compared to the existing curvy CeramicSpeed cage.

A closer look reveals that both upper and lower pulleys are solid on this prototype. Just like those Alpha pulleys of the recently introduced OSPW X for SRAM MTB Transmissions. We’re not sure. But it looks like the same composite teeth combined to a smooth alloy disc, like on the new MTB system.

This lower pulley is also marked ADR. It features that mountain bike cage’s same Active Debris Remover shaping at the central cover over the bearing. As it’s been described to us, this tangential groove shaping is a patent-pending design that pulls dust, dirt & grit away from the bearing cover as the pulley spins. A self-cleaning solution that promises even longer bearing life

Unlike the mountain bike’s X system with narrow wide teeth, this road OSPW prototype stick with a 19T lower pulley. And appears to keep 13T for the upper pulley.

How else does it differ from the current road OSPW?

Besides the more angular recent mountain bike OSPW cage with solid pulleys & ADR tech, CeramicSpeed’s latest OSPW innovation had been their fully-enclosed Aero cage. Interestingly, that one also broke cover on an Intermarché-Wanty pro’s Cube race bike.

The new road prototypes are also more angular and feature solid pulleys. We’d have to expect that the new design will be heavier – it surely has more material in the pulleys. But time will tell if that is balanced by decreased aero drag, reduced drivetrain friction, or longer bearing life.

We’ll have to wait and see what CeramicSpeed has to say once they make the new design official.

Were there actually CeramicSpeed OSPW-equipped bikes racing in the mud?

To be honest, not many.

No one actually raced this prototype here in the mud, as far as we saw. The team mounted this one to the bike of a rider who wasn’t even at Worlds, I believe. Perhaps as a backup if one of his teammates had any major bike problems.

It may have been just here to tease all the other pro riders about the new tech coming soon. But to be fair, it was so muddy out there, it’s possible that I simply missed it.

With very muddy conditions on the Tábor World Championship course, I can’t imagine there were too many friction-reducing gains to be had in a set of oversized pulleys. At least, those not offset by more real estate to collect mud on. But you know that incremental gains are always there, relative to the baseline standard. And theoretically ceramic bearings should operate more smoothly relatively – the worse conditions get and the more team mechanics clean the bikes with pressure washers.

Anyway, the U23 development team riders of Intermarché–Wanty’s CX team Charles Liégeois were sporting existing OSPW setups.

We also noticed one or two other riders on CeramicSpeed OSPW X. Like this nice SRAM AXS mullet setup. With an X01 MTB derailleur paired to an otherwise Force 1x for the easier gearing to tackle deep mud.

What else do they have up their CeramicSpeed sleeves?

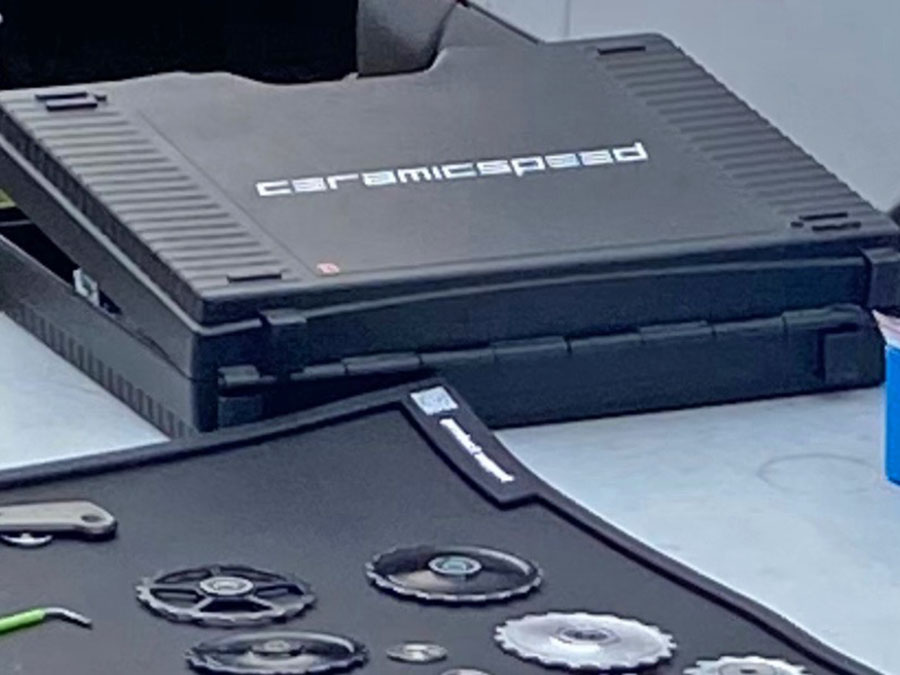

Everywhere they went – ducking in and out of pro team buses – CeramicSpeed was also carrying a small black case full of pulley cages, ceramic bearings, and who knows what else.

Probably some of their UFO Drip wax lube that is quite prevalent in top-tier racing.

We only officially see CeramicSpeed logo stickers on a few pro road and a couple pro XC mountain bike teams. But, we’ve definitely seen OSPW cages on a number of other ‘non-sponsored’ bikes. And against the high cost and focus on aero gains of most pro bikes these days, it seems like a relatively small leap for more pro riders to see if CeramicSpeed can deliver on their promises of incremental gains. Rumor in the peloton – both on- and off-road – suggests that CeramicSpeed supplies a LOT of additional teams. And all the times we saw CeramicSpeed crew pop up all over the CX Worlds pits backs that up.