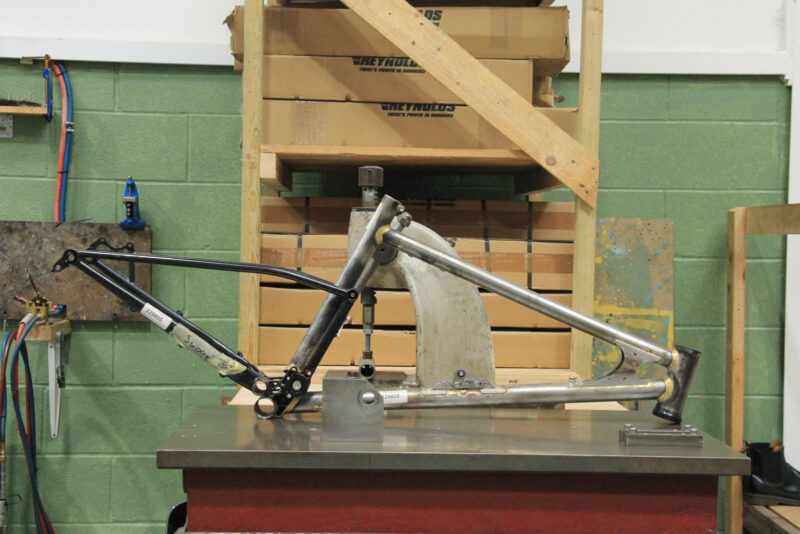

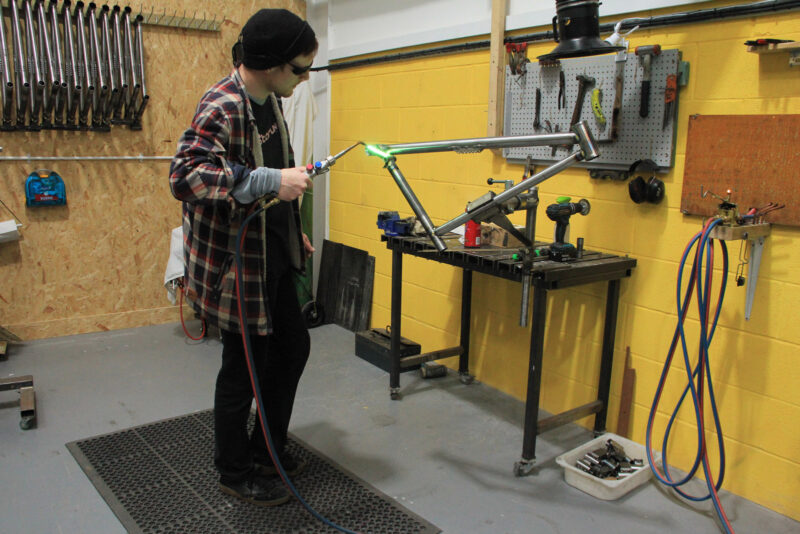

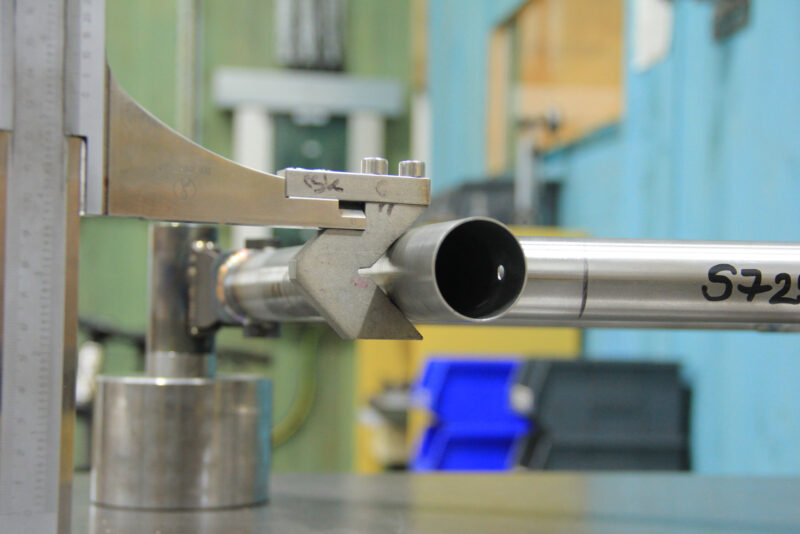

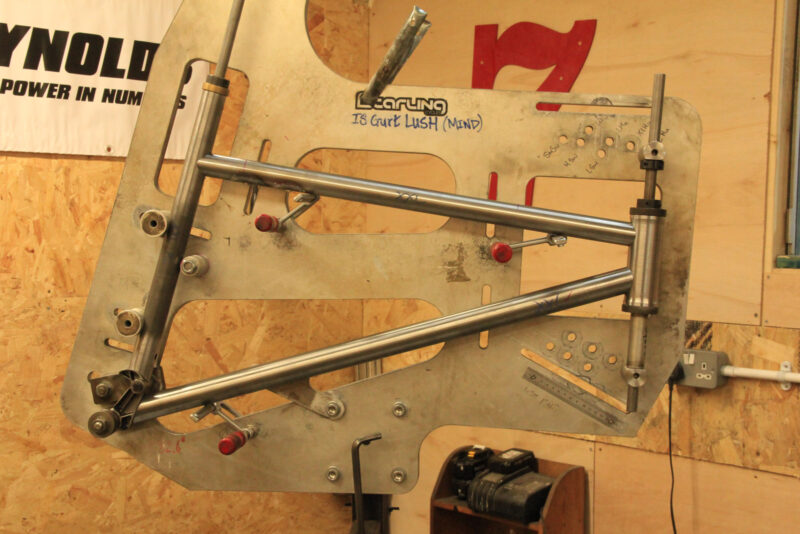

Starling Cycles is a UK manufacturer of steel mountain bikes, most well known for their aesthetically-pleasing executions of the humble single-pivot suspension platform. The brand has come a fair way since its fledgling garden shed setup in 2015. At the moment, Joe has seven current production frames to his name. The front triangles of most of these frames are fabricated in-house, at their Bristol workshop. Meanwhile, the majority of the swingarms are manufactured in Taiwan.

The Swoop 27.5″, the Twist Mixed-Wheel, the Murmur 29″, and the recent MegaMurmur trail and enduro bikes form Starling’s “core” lineup. But, they also manufacture some rather more “rare” models. These include the wildly fun Roost Hardtail, the Beady Little Eye (a 90mm travel mixed-wheel single-speed), and the Murmur Stainless. They also offer a custom frame building service for anyone after something special.

But, Joe is something of a tinkerer, and is seemingly always working away on special projects. Some of them he labels “exercises in R&D”. Others are simply so niche that a limited production run is the only viable option. Superb examples of the latter include the Spur – a high-pivot 170mm travel gearbox-equipped enduro bike – and the Sturn – a single-speed high-pivot downhill bike with a Jack Shaft drivetrain arrangement.

Earlier this year, we stopped by the Starling Cycles HQ in Bristol, to find out what founder Joe McEwan has brewing for the company’s future.

All photos from Bikerumor, unless otherwise stated

Interview | Joe McEwan on What’s to Come for Starling Cycles

Bikerumor: This year, you launched the V3 Murmur, Twist and Swoop frames. During their development, did you ever consider moving away from the single-pivot suspension platform and if so, for what reasons?

Starling Cycles: I love single pivot! With modern coil shocks it rides as good as multi-links, if not better in many cases! I would like to have a vertical shock sitting close to the seat tube: for aesthetics, commonality in manufacture between sizes and more frame space. But I can’t see how to achieve this elegantly without a linkage, so it’s a compromise too far!

Bikerumor: You have dabbled in the use of gearboxes, specifically with an Effigear unit on the Spur – a bike you say is the best descender you’ve ever made. Do you think the gearbox mountain bike will ever make it into the mainstream, and do intend to bring a gearbox-dedicated frame to production?

Starling Cycles: The Spur gearbox bike we made was amazing. The suspension performance and silence made it the most amazing descending bike I’ve ever ridden. But, there is a little bit of drag which means it is best suited to a more gravity orientated bike. I don’t think meshing gears at low revs will ever be as efficient as a chain, someone more knowledgeable on drivetrain systems can agree or disagree, no doubt.

We had some production issue with Effigear, mostly due to Covid supply chains, but it seems they are on top of it now, so we may be offering the Spur again sometime soon!

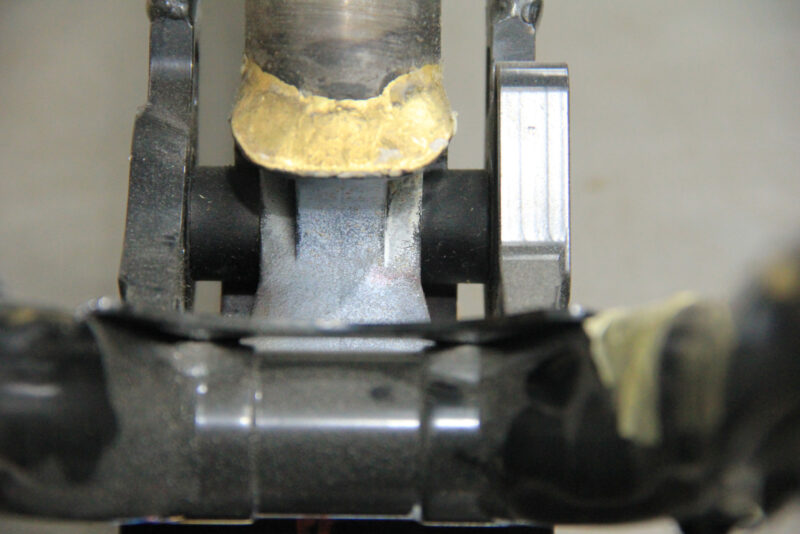

In terms of the gearbox, in house we now have a design and are manufacturing a prototype 2 speed box, primarily intended to trial the technology. Subsequent versions will have four gears.

Bikerumor: In your workshop, there is a steel eBike hanging from the demo bike rail. Will we be see a Starling Cycles eMTB in the not-too-distant future? If so, can you give us any info on how it will materialize?

Starling Cycles: The steel ebike never really worked out. It’s pretty tricky to accomodate the complex shapes needed for motors and batteries and suspension in steel. But, I think as motor and battery technology allows for more compact systems, I might be able to do a Starling ebike and still keep the elegant design I value so much!

But, there is also the counter point that Starlings definitely don’t look like ebikes. Whereas, with many fat tubed carbon bikes it’s tricky to tell. So, if you are at the top of a hill on a Starling, everyone knows you pedaled it up to the top!

But, I’m also working on a parallel project under a new brand to develop a pretty special ebike, so keep your eyes open for that one….

Bikerumor: Last year, you teased a carbon eMTB with braided, thermoplastic tubes, developed in collaboration with the National Composites Center. Can you give us an update on that project?

Starling Cycles: This project is moving ahead, but slowly. That’s all I can say!

Bikerumor: Mountain Bike geometry has come a long way in the last 5 years; do you think we have reached the pinnacle of the long, low and slack geometry trend, or do you feel there is more to be gained from pushing this further?

Starling Cycles: Mountain bike geometry has changed, and we have a better understanding of what is required for different types of riding. The long, low, slack suits rough high speed terrain, but maybe at the expense of some pop and maneuverability. Personally, the more I think about it, the more I think we need to think about how we ride and what geometry suits our needs, rather than just thinking making it as long as possible is best. There’s an ergonomic aspect too.

So to try and condense my thinking: Longer stays add maneuverability, shorter stays add pop and maneuverability. You need to pick the compromise to suit your riding style.

Taller riders need bigger bikes, bigger bikes need longer stays to balance out the bike. And, the reverse for shorter riders. Longer travel bikes add grip and bump eating at the expense of pedalling and pop. Shorter travel bikes provide a firmer platform for better pedalling and pop, at the expense of grip and bump eating. You need to pick the compromise to suit your riding style.

Wheels/tyres have a massive impact on how bikes ride. Heavy wheels and tough tyres for grip and control, the weight actually keeps them stable in the rough, but they are harder to pedal. Light wheels and fast rolling tyres for pedalling speed on smooth terrain and fast climbing, but they are terrible in rough terrain. You need to pick the compromise to suit your riding style.

My main thought is that nothing is the golden ticket, you always need to pick where you want your compromise to sit. Although, marketing tries to tell you otherwise, it’s just not true! I try to provide a range of bikes that allows you to pick the compromise you want with minimum hassle!

Bikerumor: Do you have any predictions for where mountain bike technology is headed in the next 10 years, and how will Starling Cycles be a part of that?

Starling Cycles: I have a bit of a conflict on this. I’m an engineer and I love technology and improving performance. But, we’re biking for fun, even with racing we’re mostly doing it for fun, and we had as much fun on bikes from 20 years ago as we do now.

I think the incremental gains we see now are driven more by marketing and the need for change than any actual greater enjoyment for the sport. I suppose the fact they don’t break as much anymore is a positive. But other than that, we’d have as much fun on a Klunker. I think the emergence of gravel is partly driven by this.

So, I think the trend for the future is less technology and more engaging riding on stock Klunkers with ‘standards’ that are real standards!

Bikerumor: What are the major challenges faced by the small to medium size bicycle manufacturers in Britain today?

Starling Cycles: Being a British Manufacturer is not easy. Without getting too political, manufacturing is just not valued in the UK. The people making money, with minimum risk, are estate agents (don’t get me started), lawyers, solicitors, finance, marketing people. They add nothing, but take everything. Whereas in the EU and many other places it is understood that manufacturing is key to a strong economy and it is respected. Engineers are respected, not just seen as weird geeks.

British manufacturing is also devalued, particularly with bikes, by companies claiming their products are UK manufactured, but in fact they are only assembled here from parts made elsewhere. We get our swingarms made in Taiwan, but are very transparent about it, other companies are much less transparent…

We need to be proud of what we can do here and shout about it. There’s lots of great UK brands doing exciting things with manufacturing in the UK; Starling, Atherton Bikes, Stanton, Moulton, Brompton and many more. The rest of the world take pride in supporting their local brands. UK manufacturing was killed in the 80s with crap cars, so nobody buys British anymore! So, we will struggle on. Sorry, that did get a bit political.

If you were to order a frame today, you’d wait somewhere between 8-16 weeks for delivery. Starling are working hard to increase their UK production capacity through training a third frame builder to join the team, hoping to bring lead time down to around 4 weeks.