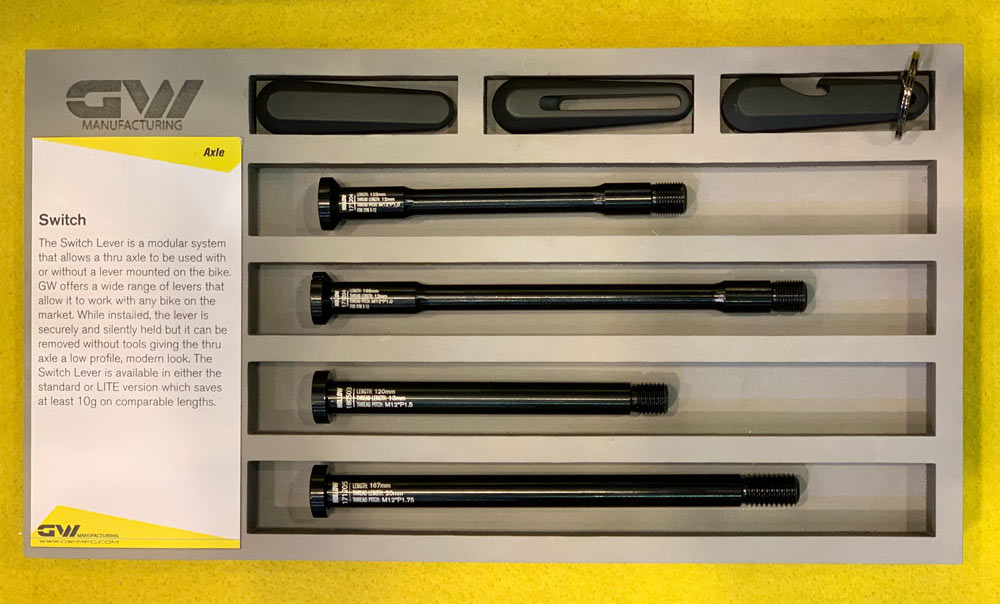

The SwitchLever is a fairly standard thru axle option with one nifty trick up its sleeve: A disappearing lever. The result is that your bike can have that clean look of tooled thru axles, but without having to use a floppy mini-tool to change a flat on the side of the road. The included lever detaches, leaving a smooth dropout area, then snaps in when it’s time to install or remove your wheel.

Thanks to a variety of thread pitches and lengths, they’re available to replace virtually axles you may have. Options include:

Front/Rear 12mm Thru Axles

- Lengths from 100mm to 230mm

- Thread pitches: M12*1.0/1.5/1.75

- For axle standards of 100, 142, 148, 157 and 197 mm

- X-12 option

Front 15mm Thru Axles

- Lengths from 110mm to 199mm

- Thread pitches: M15*1.5 or M14*1.5

- For axle standards of 100 and 110 mm

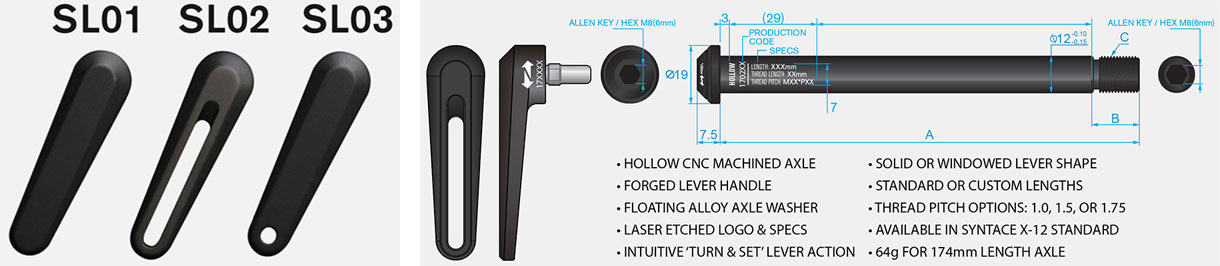

The lever handles come in solid and hollow (a bottle opener version is in development, shown below), with the hollow one weighing just 24g. They say the average axle weight is 41g, obviously more for longer axle widths. These levers can be used on most any tooled thru axle, but their axle is designed to capture it so it won’t fall out if you decide to leave it in. Once tightened, you can pull it out and reposition it to the desired angle.

The SwitchLever is spec’d on the Mason Revolution 2 road bike that launched earlier this year, and OEM spec seems to be where their interest lies. They’re a manufacturing company based in Taiwan, with no specific product pages on their website, but they’ll make the axle in any custom length and thread pitch. Contact them directly if you’re interested, and we’ll update if they add a consumer-facing site.