Just like it says on the Appalachian Bicycle Institute (ABI) webpage, Jenny Kallista’s bicycle mechanic’s school is “located in beautiful Western North Carolina”. The location is just outside the city limits of Asheville, NC, and smack dab in the middle of a virtual bicycle innovation think tank. Links on the ABI site lead you down the road to the innovators at Endless Bikes, By:Stickel, Industry Nine, Cane Creek, Suspension Experts, and local race production companies Blue Ridge Adventures and Pisgah Productions.

Thus, it’s not surprising that the Appalachian Bicycle Institute is putting a new spin on honing bike technician skills. There is an informal collaborative environment in the Ashville area that links mountain bikers, roadies, and racers to people heavily involved in maintenance issues and new design. This creates great feedback to the school providing ABI with a strong sense of its students needs. Jenny takes a hands-on approach to teaching her classes that keeps the class size small with a high degree of personal attention. The environment at the school is an interesting mix that ties an extremely neat and detailed work area to a homespun casual social setting. When a student is working on the bench, he or she is expected to observe highly organized and clean working techniques but during social periods such as lunch, the group kicks back together to enjoy whatever great meal Jenny has provided.

For the FOX Master Suspension class, ABI collaborates with FOX Racing Shox, who provides a highly qualified technician/instructor to cover the basic fork overhaul and advanced damper cartridge service. The class takes students through a detailed (and I do mean DETAILED) explanation of front and rear suspension components and overhaul of FOX’s more popular forks. While it would be impossible to cover every model of fork FOX produces in a two-day class, the knowledge gained crosses over to other forks in the lineup. For the class I attended, Nick DeLauder from FOX came to instruct.

After talking to Nick, I do not believe he initially set out in life to become a technical instructor, but the role fits him to a tee. Nick is easily one of the most detailed individuals I have met. He also displays a high level of efficiency and spatial awareness.

So… what’s all that mean to the student? While some instructors teach their students how to do a task through rote memorization, Nick spends a lot of time explaining the “why’s” to his techniques. As he explains, and I’m paraphrasing here, if you understand “why” things do what they do, then you’ll be able to figure out “how” it should go together. This type of thinking and instructional technique takes the student down the engineering side of the suspension puzzle where they gain insight into the function of the parts and how they interact with the system as a whole. All suspension questions were fair game during class because the orientation was towards the student’s point of reference instead of being lockstep with a predefined curriculum.

This is not to say that the instruction was haphazard; it was not. However, the instruction was very flexible to the attending group’s base knowledge. As I stated above, Nick pays close attention to efficiency and spatial awareness. Not only were we learning how to work on a part, but we were also learning how to approach tools, how to stand, best practices when using tools, and most effective methods to reduce or eliminate damage to the parts being worked on. By spending many hours working on these forks, Nick and his colleagues at FOX have developed techniques that will help the student in their approach to all bike maintenance. The techniques will also limit the number of small parts you lose during routine maintenance. But I did see at least one small spring shoot across the room during class. Yes, we found it.

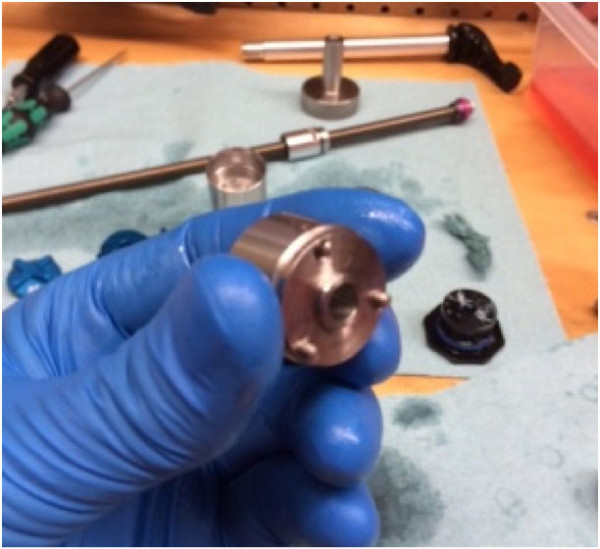

During the class, we took our forks apart piece by piece with detailed instructions from Nick on the function of each part as it came apart. We would then go to the diagrams and parts lists published by FOX to discuss how to best use the tools and information available on the FOX website. This included determining whether a fork could be upgraded, changed in model type (such as converting a Float to a TALAS), shortening or lengthening the travel, and who to call when stuck on one of these questions. Because Nick was the tech writer for much of the documentation we were looking at, there was constant dialog on how to best use the products. Once everything came apart, we flipped to reassembling the forks.

Reassembly included the same level of explanation on technique and efficiency seen during breakdown. Nick’s systematic process ensured every student saw each internal procedure two or three times and did hands-on disassembly/assembly of all components within the fork and damper at least once. The teaching gave every student a very thorough run through of the mechanics involved in fork and damper service.

FOX or ABI supplied all specialty tools required to accomplish our tasks properly and usage of these tools was gone over in detail. I am quite sure that all students were building their tool order wish list in their heads during their drive home. Jenny’s classroom included everything needed to accomplish all tasks and then some. Her classroom is fully stocked and organized to establish good shop practice. All essential tools fall quickly to hand and when moving from workstation to workstation the bench setups remain consistent. The classroom was a very efficient and logical layout.

This was a great class. The overall classroom environment is excellent and I look forward to another trip up to Asheville to take one of ABI’s other classes. I was highly impressed with Nick Delauder as an instructor. He made me rethink all my maintenance techniques throughout the whole class; not just suspension specific ones. Nick is also a genuinely nice guy. At the end of the first day, one of the local riders dropped in with a 2008 long travel FOX Talas fork. Nick took the opportunity to help the young man out and provide those that were able to stay late a foray into the older designs that shop mechanics might see back at their home shops. We spent about four hours looking at older damper design and comparing them to new design improvements. As an added bonus, Steve Stickel of By:Stickel Handcrafted Custom Bicycles, dropped in that evening and gave me a thorough rundown on 29’er frame design, proper chainstay length, fixing chain centerlines and why good bike design has an element of instability designed in. He touches on some of this on his website, but talking through it while standing over a bike cleared up some standard misconceptions. It was a very enlightening discussion that made great sense.

At the end of two days, I was maxed out on retention of new information and was excited to get back home and start improving service on my own bikes. I would highly recommend this course to anyone involved in bike maintenance. I would also recommend any of ABI’s other courses to help round out your understanding of bicycle mechanics. Even the most experienced bike tech will learn something new in this type of environment. FOX’s Nick DeLauder was saying that he continually learns during the clinics.

When anyone gathers a group of diverse techies together, he or she can expect to hear from the field about issues he or she may not have encountered previously. This process provides valuable insight into possible ways to solve customer issues. There is a lot to gain by everyone involved. Great class, great instructors, great town, great local trails, and great food makes for a great weekend. Very highly recommended.