Having your own signature product is a good indication that you’ve made it as a professional rider. But it also means that product that has your name on it has to live up to expectations. When Deity approached Tyler McCaul to build his signature pedal, the two along with other Deity team members like Cam Zink put a lot of thought into what would appear to be a simple platform pedal to many.

Wanting the biggest, most supportive pedal you could build, Deity’s TMAC pedal is ready to make slipped pedals a thing of the past…

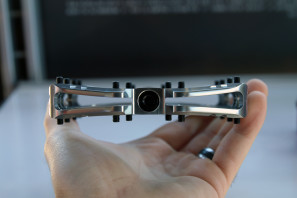

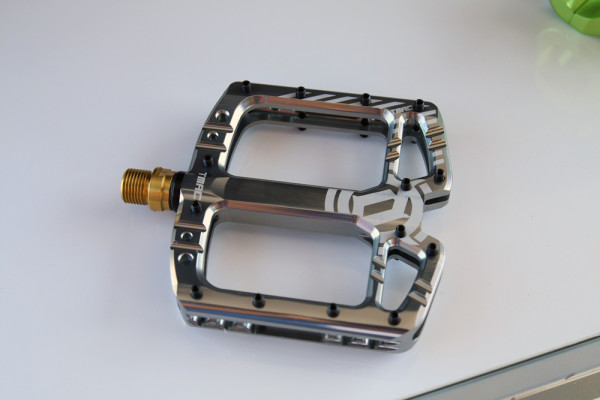

Earlier this year we got a sneak peek at the TMAC when one of the first samples was on display at Sea Otter. Holding the pedal in your hand, you get a sense of the massive 110×105 mm platform as well as the super deep concave shape which dips 2.5mm in the center. Riders wanting something flatter should check out Deity’s Bladerunner.

“We were initially worried about the effect a symmetrical pedal at a 90 degree right angle would have when the foot tried to stomp down and engage back on the platform. Would the foot shift forward or backward more? Would there be a delay on the engagement? To test this we made a weight driven machine that would apply downward force on the pedal when placed on a 90 degree plain. We could then measure the time it took for the foot to land flat and securely on the pedal and also, where the foot ended up being in relation to the axle when it rotated horizontally. We could then move the foot location forward or backwards to then test stability when the foot is not in the ideal position. The results were as we thought they would be. The added surface area behind the spindle allowed the concave profile to really shine. The foot confidently had space to connect to the pedal without worry of lack of foot support or needing to be in the perfect location.” Eric Davies (Deity, Owner).

If you look at most platform pedals, they are shaped like a slanted parallelogram with the actual pedal platform shifted forwards from the axle. What Eric is referring to is the fact that the TMAC platform is centered on the axle with a symmetrical design. This is said to give better support when landing big jumps or tricks, especially when your feet aren’t quite on the pedals.

Made from extruded and machined 6061 T6 aluminum, each pedal includes 14 pins per side. Typically, grub screws are frowned upon for traction pins since one rock strike can damage the allen screw, making them very difficult to remove. For the TMAC though, each screw is double sided and can be removed when damaged by removing the pin on the opposite side and using the preserved allen screw underneath. All pins are pre-applied with LocTite so they should stay put, but if they happen to eject the pedals include a full replacement set.

Other details include a heat treated chromoly spindle that runs on multiple micro sealed bearings and a DU bushing that are arranged to distribute pedal load to prevent blowout.

Available in 5 anodized colors and white powder coat, TMAC pedals have a claimed weight of 409g, and will sell for $168.99. Available now.