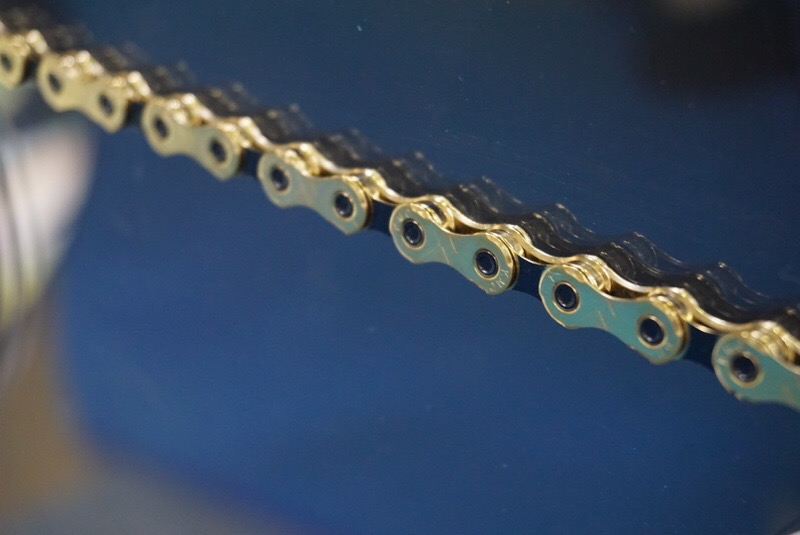

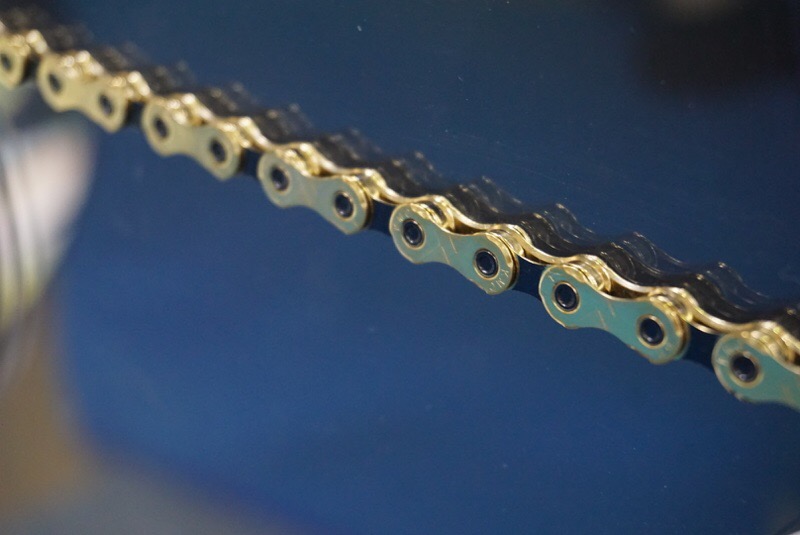

Much as they did with the X11 to optimize for 11-speed systems, the new KMC X12-1 chains get fine tuned for 12-speed drive trains. The X-Shift pattern involves much shaping, with chamfers, cuts, and slants all designed to make it run silent and shift fast across the entire cassette range. And up front, presumably important if road bikes start going to 12 speeds, too.

On top of that, they’re not offering it with this gold-hued titanium nitride coating to make it shift even better by helping it stay clean…

Hit that link up above for closeup detail of their plate shaping and an explanation of why it helps.

The X12-1 chain will be available in full gold, gold/black and silver, but the most benefit comes from the full gold model. They say the Ti-nitride coating creates an ultra smooth surface that sheds mud and grit more easily, and a cleaner chain means smoother pedaling, faster and more precise shifts and less of that grating noise that constantly reminds you you’re wearing out that very expensive 12-speed cassette.