Venn manufactures a variety of different carbon rims, and they’re making a bold claim about their latest rim brake carbon clinchers: “Venn rim brake rims do not suffer from heat damage.” If that wasn’t enough, they say that their Var 77 is the first rim ever designed by autonomous artificial intelligence. Paging Elon Musk…

Venn Var rim brake carbon clincher wheels

This isn’t the first we’ve seen from Venn, who tout an interesting filament wound, single strand carbon construction. However, this time it’s all about heat-resistant rim brake carbon clincher wheels – the Var TCC series. Using a high temperature resin matrix and complex 14 hour post-cure process, they say that it “almost guarantees that your rims will remain safe and functional in any real world situation when using suitable pads, well adjusted brakes, and appropriate braking technique.”

Oh, did we mention that they say that the Var 77 is the “first rim ever designed by autonomous artificial intelligence“?

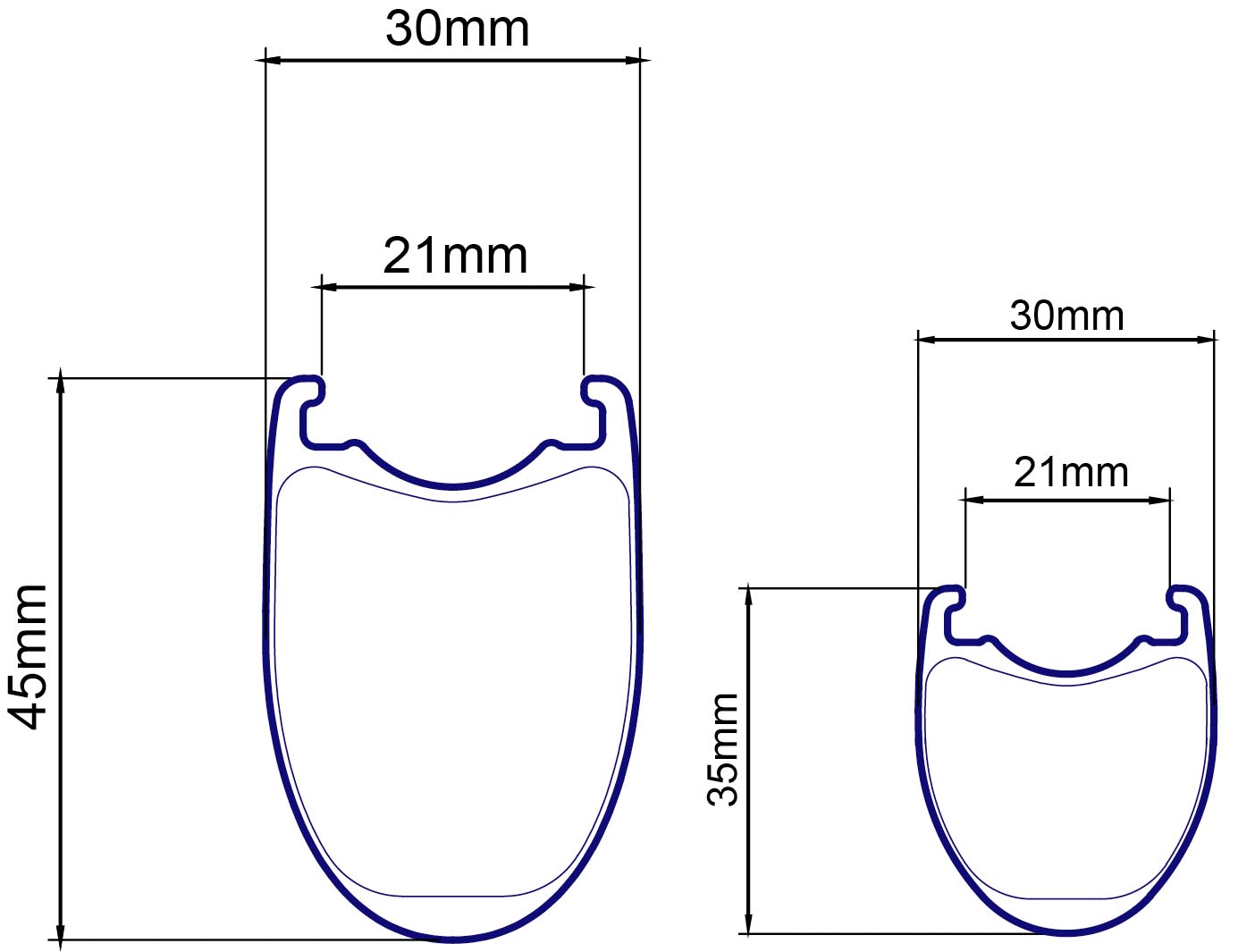

There are three depths available in the Var series – 35, 45, and 77mm. All use the same 21mm internal width, putting them on the wide end of the spectrum for rim brake wheels.

How do they go about making rims that can’t be damaged by braking heat? Here’s the download straight from Venn:

“We test our rims to failure before we release them to the market, and follow up after the rims and wheels are in use to identify any possible failure mode, and make improvements as necessary.

We are now happy to share that it is physically impossible to cause heat damage to our rims when riding your bike.

Our own efforts to melt our rims failed since in repeated attempts to do so all we managed to do is melt the inner tube and cause a tire blowout which ended the attempts.

Thus, while the rim cannot be damaged it is still important that you allow the rims to cool down sufficiently to avoid tire failure – this also applies to alloy rims.”

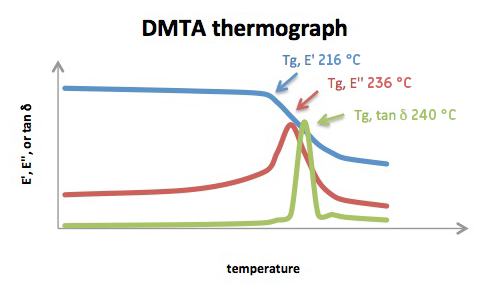

The key, according to Venn, is a high glass transition temperature, or Tg:

“Tg is the temperature at which otherwise stable epoxy resin matrix holding the carbon fibers in place effectively irreversibly degrades causing permanent damage to the carbon fiber composite material – a bicycle rim in this case. The only significant source of heat in bicycle rims is the heat generated by rim brakes.

Venn Var rim brake rims feature custom developed high glass transition (Tg) resin that resists softening and loss of mechanical properties at average temperatures of 240° C

Tg is not a single number, but a range determined via differential scanning calorimetry (DSC) and dynamic mechanical thermal analysis (DMTA)). Such a high Tg almost guarantees that your rims will remain safe and functional in any real world situation when using suitable pads, well adjusted brakes, and appropriate braking technique.”

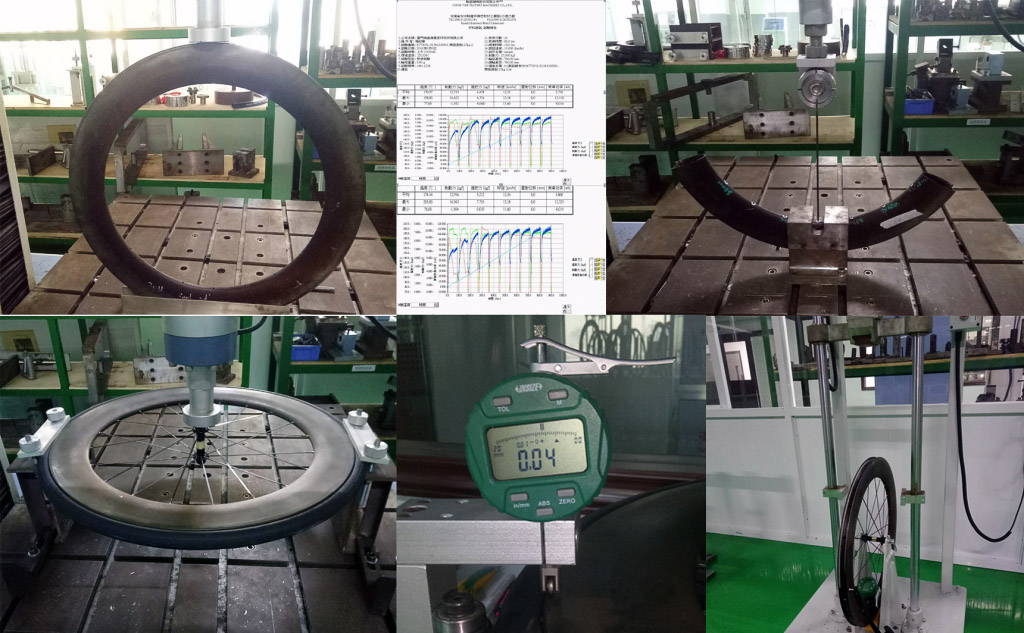

Venn says that every Var rim has to pass a rigorous quality control test that includes inflation to 150psi, spoke tension to 130kgf, a 300kg radial compression test, and more. They also report doing batch testing using X-Ray imaging to identify any potential lamination issues before the rims are released into the wild.

The Var line is available in complete wheels or as a rim-only, starting at $374.