The new Velocite Venn Var carbon rim claims to be the first-ever bicycle rim designed completely by A.I. The design was iterated through computational fluid dynamics software, and the project was led by CFD/AI expert and mechanical engineering professor Matthew Smith at the NCKU in Tainan.

Using AI allowed their team to iterate designs much faster than they could have by manually reviewing the results of each and every design change. Smith’s AI optimization routine was first programmed to find the lowest drag cross section possible that would work with a 25mm tire. They constrained the depth to a maximum of 77mm and let it fly.

The initial result was a rim that measured 42mm at its widest point, so they added a width constraint of 30mm so it would fit in traditional bicycle frames and forks. There were no other constraints to shape or size because Velocite founder Victor Major wanted to give the AI full autonomy to design the best possible shape it could.

The program went through 675 2D profiles before it found the best ones, then the design was put into 3D simulations to narrow down those candidates. Once the best performing rim shape was found, they machined the mold and got ready for production. But not just any production…

A new type of carbon filament winding

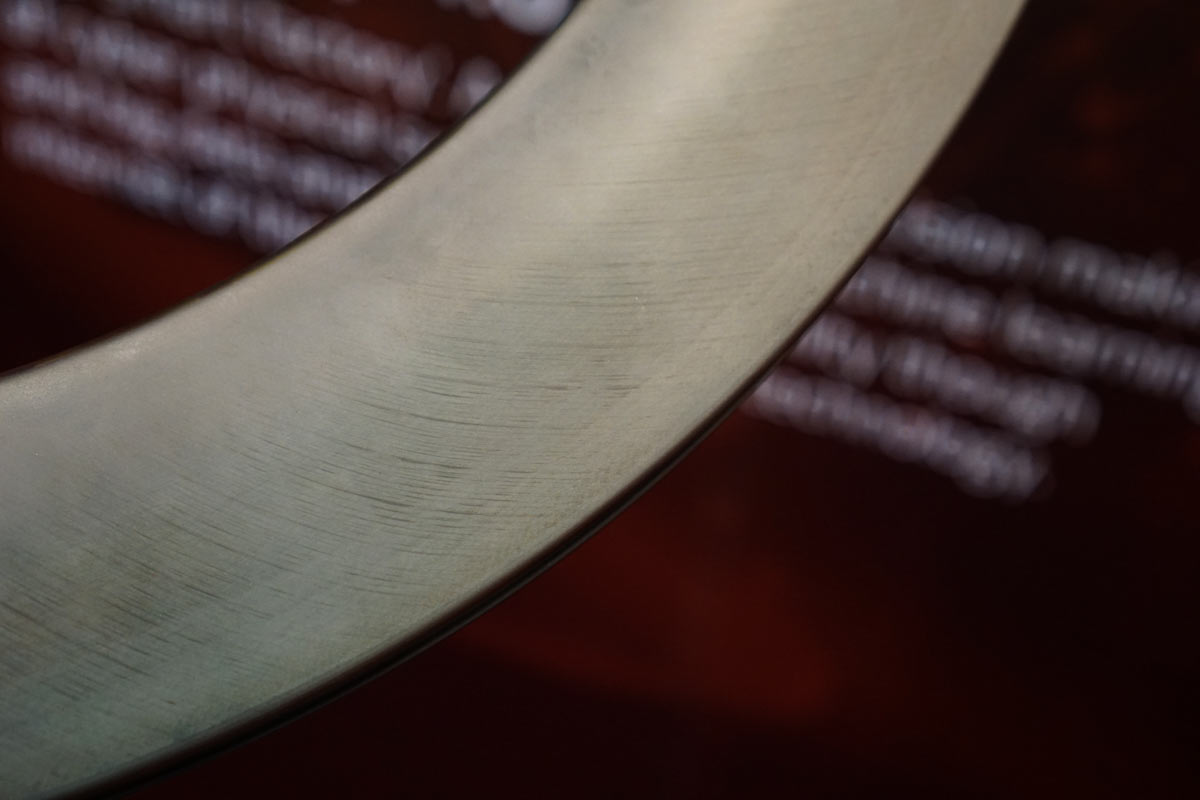

The prior Venn Rev rims used a very unique construction process called filament winding. We’ve covered it in great detail before, but the nutshell version is this: Carbon strands are pulled through resin then wound around the mold. The process allows extremely precise control of fiber placement and minimal excess overlap.

For the Venn Var rims, they took it one step further. The Var process uses thinly slit carbon fiber prepreg tape rather than individual strands, which they say is less susceptible to environmental changes. Meaning, they can make the rims in a wider range of temperatures and humidity conditions, which should lead to higher production outputs and more reliable supply. They’ll continue to use both Rev and Var methods as the former allows for more shapely designs for rims where aerodynamics are not the top consideration.

Specs for the new rims and wheels are:

- Width at brake track: 29mm

- Maximum width: 30mm

- Depth: 77mm

- Weight: 625mm per rim

- Clincher wheelset: Venn Var 77 TCC weight: 1894g

- Disc brake wheelset: Venn Var 77 TCD weight: 1915g

They’re available now, complete wheels are $/€1,499. Rims are available separately for $/€469 each.