Formula may be a small company when it comes to mountain bike suspension, but they’re not afraid to go big with new ideas. Introduced in April (but in development since 2011!), the Formula NEOPOS dynamic air volume spacers offered a radically new way of thinking about air volume adjustments. By using a soft, squishy material that compressed along with the air inside your fork, they could provide the benefits of an air spring and adjustable volume, but in a way that (they say) more closely mimics the feel of a coil spring fork. Here’s everything you need to know about NEOPOS and how it works:

The NEOPOS spacers are a closed cell foam with air bubble trapped inside. That air compresses as the same rate as the air that you’ve put into the positive chamber. So, they change their size almost in direct proportion to how much your air compresses…to a point. The spacer material itself won’t compress, so it won’t be an exact correlation, but close.

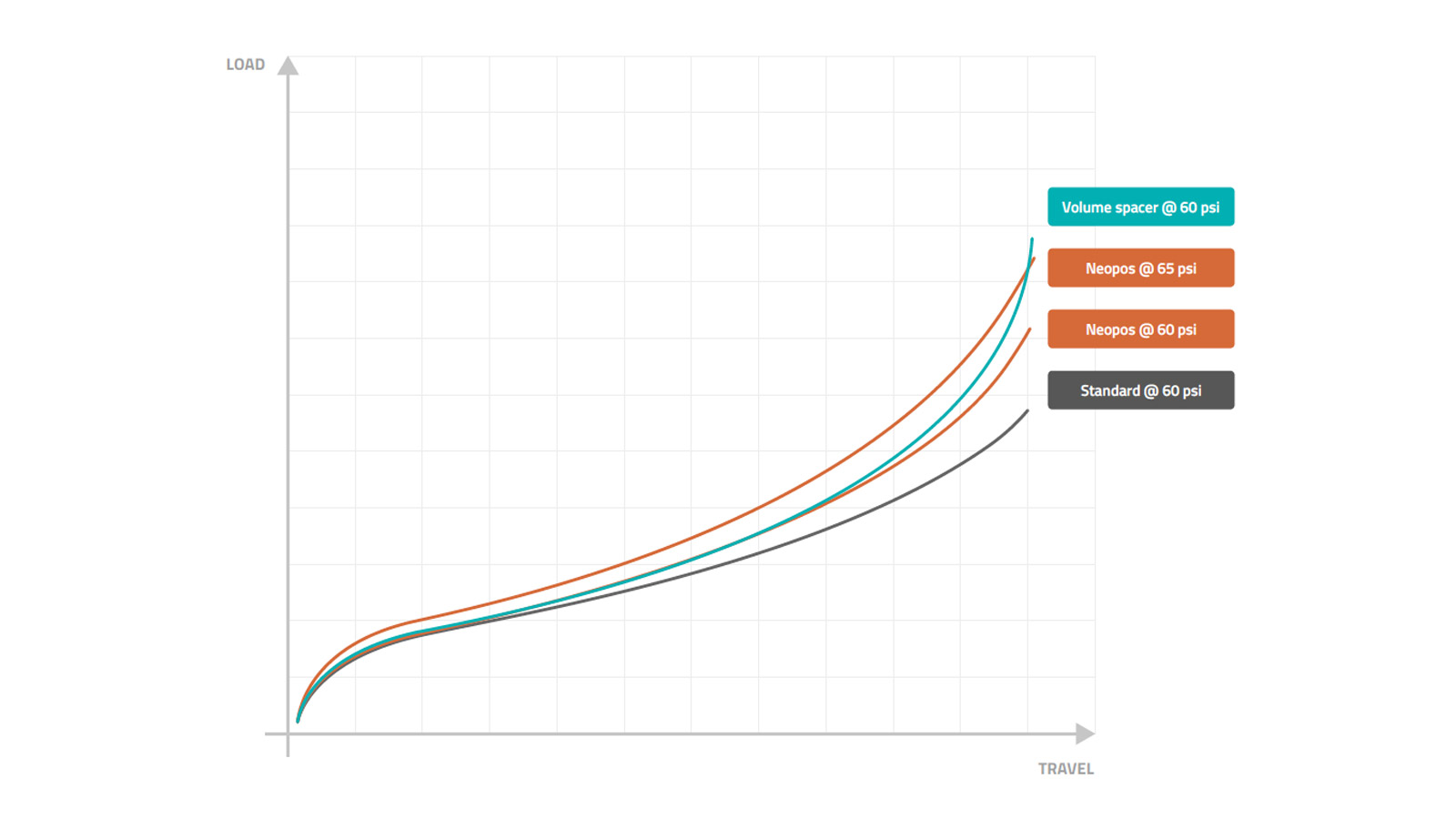

Because they change shape, they closely mimic a standard spacer through the first part of travel, but end up having less impact at the end of the stroke. Still enough impact to prevent a bottom out, but leaving you with a less harsh ramp, so there’s a more plush feeling overall. The chart below shows how it can deliver a similar end-of-stroke support by adding more air pressure, which is just one way of tuning it. Click image to enlarge:

Want a softer fork on initial travel with a bit more ramp at the end? Use two or three NEOPOS spacers instead and keep the air pressure lower. It’s all about tuning for your type of riding, weight and trail conditions.