In economics, there are two theories that define the tradeoffs made in any business decision – Opportunity Cost and Sunk Cost. No one knows this better than Ted Ciamillo.

Over the past couple years since we visited him for a factory tour, Ciamillo has poured countless hours and dollars into his Gravitas crank project. With that project now on hold, those irreclaimable resources would be a sunk cost – they’re gone.

With so much focus on it, his bread and butter brake caliper business suffered. Delays. Rejected parts. Too long delays in responding to customers. You name it, and there’ve been online comments to support it. That was the opportunity cost – the business and good will he’s lost while chasing the dream of building the lightest, stiffest crankset known to man.

Since our visit, I’ve spoken with Ted many times and at length about his business. See, I’ve had several businesses before starting Bikerumor and been through my own share of lost opportunities and hard lessons. I can sympathize. I’ve been there. It’s not fun. And in many of our conversations, the stress came through in Ted’s voice. There are few things more painful than watching something you built from the ground up stumble and fall, yet we entrepreneurs are a tough bunch. Sometimes we don’t know when to quit. And sometimes, that perseverance can pay off…

THE REBOOT

Time spent on the cranks aside, one of the other issues plaguing the business was production capacity. Not only were the CNC machines limited to just a couple caliper bodies at a time, but Ted says his employees simply didn’t have enough attention to detail, which led to too many of those already sparse parts being rejected. As in, almost 80% rejected at times. A tight supply became even tighter, and payroll was being spent without generating enough return.

The solution? Put the cranks on indefinite hold and fire everyone, even his dealers. As of June 2014, Ted Ciamillo is now making 100% of his brakes 100% himself. And once current dealer orders are fulfilled, he’ll only be selling direct to consumer in North America. His two international distributors, one in Europe and one in Asia, will remain.

That solves the quality control issue, but one person can only do so much. To bump production, he had to reprogram all of his machines to cut more parts at a time. When they were making just two caliper bodies per cycle, his main CNC router needed blanks reloaded about every four minutes. That constant attention left little time to do important things like, you know, sales and customer service. Yes, that’s why your phone calls and emails weren’t being returned, and many times ours weren’t either. To be fair, it’s not uncommon among small, artisan builders. We rarely hear from or hear back from 99% of the handmade frame builders. Even many of the mid-sized brands are so overwhelmed and running on a skeleton crew that communication is tough. Unfortunately, it’s just the nature of business these days. Ted knows it’s a pain point, he’s sorry, and it might yet be some time before it gets much better.

With these changes, the machines can now handle larger blanks and cut 30 to 36 parts per cycle. Cycle times are now up to three hours at a stretch, leaving time to assemble, anodize, package and ship. Another cycle is set to run after lights out, leaving freshly made parts ready in the morning. Maybe even return a phone call or email or two. (yes, that’s sarcasm) The brakes are made in batches of 50 in 10-day blocks. Not mass production, but way better than it’s been.

So what’s the benefit to you, the cyclist? Why should you care?

Well, if you’ve had a pair of brakes on order or a customer service inquiry in the queue, it means things should be on their way soon. Ted said his backorder log is rapidly getting caught up, and anyone that’s been waiting for too long will get a pretty fair discount.

The other benefit of improved efficiency is a change in pricing. The GSL brake set will drop to $259 from $369. The new Micro drops from $429 to $279. International orders add $20 to $30.

The last reason to care? Because the brakes are amazing…

FIRST IMPRESSIONS – CIAMILLO MICRO ROAD BRAKE CALIPERS

Let’s start this story many years ago. When I reviewed the Feather Brakes, I swung by a local shop to get a few opinions of them. They liked them, saying they were much more powerful than the equally-light-at-the-time Ciamillo Zero Gravity calipers. It wasn’t the first time I’d heard some version of “Oh, yeah, Ciamillo brakes are super light but they have no power.”

My gut feel, though, was that there had to be something to his brakes or he’d have been out of business long, long ago. After all, many of the custom bike builders I know run them despite similarly lightweight options available. And Ted says he has many, many repeat customers. He says the trick, if you can call it that, is setting them up properly.

A few months ago I finally had a chance to test them for myself, and here’s what I think. Yes, they are amazing, and yes, you absolutely need to set them up correctly.

Ted knew set up was plaguing some folks, and without the cable properly installed, power could indeed be limited. The issue was using the barrel adjuster to take up cable slack and bring the pads in proper position next to the rim. By pulling the cable via barrel adjustment, you effectively bring the leverage arm that the cable clamps to closer to the barrel’s support arm. When that happens, you’re not getting the full amount of arm movement, potentially bottoming the cable lever into the bottom of the barrel and preventing the brakes from closing further. That limitation on closure is what made them feel less powerful. The reality was the incorrect install had simply prevented the brakes from working as intended.

Make no mistake, set up is still critical. But the new Micros introduced an adjustable cam that make fine tuning the position much, much easier.

There’s now a small bolt in the cam, visible from the top (silver, just to the right of his logo), that’s easily accessed. Get the brake pads within 1.5mm of the rim’s braking surface, then fine tune their position with that screw. Adjustments there don’t affect cable pull at all, leaving full lever travel available.

The other benefit to the design is the front facing cam lever. It allows for quick wheel swaps between narrow and wide without having to loosen the cable bolt and mess with cable position. On the left, it’s shown closed, on the right, open. It’s a substantial 6mm difference.

Here’s what it looks like from behind. Note the cam’s pivot position has changed, which opens and closes the brakes.

The cam’s adjustment bolt pushes against the lever arm that’s pulled by the cable. The cam has a roller between it and the brake arm to keep things rolling smooth. The design is good enough for SRAM to license it for their top level mechanical road brake calipers.

Any extraneous alloy is machined away to save grams. You won’t find this level of attention and drillium on mass produced parts.

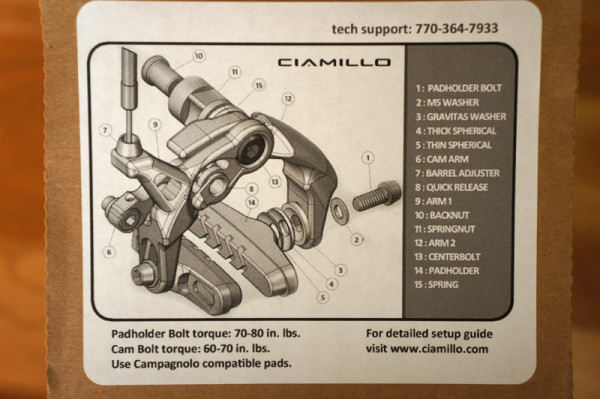

Even the pad carriers are machined away. Ciamillo used to provide pad carriers in multiple thicknesses. Now, just a single version is offered and multiple thickness washers are included:

Before adjusting the cam and finalizing cable position, these are the first step in setting the proper brake pad distance from the rim. Use none, the thin, the thick, or both washers to get things close, then the cam adjustment fine tunes it.

Set is still a bit finicky in that it really, really helps to have a friend help hold the lever down while clamping the cable tight. If the arm pulls up a bit, you end up with a little slack in the line that can become unnerving. The only other complaint is that the cable groove points straight into the arm, so you’ll have to bend it a bit once it exits the bolt’s washer.

OK, actually two more small complaints: The brake pads, which need to be Campagnolo, are a royal pain in the arse to cram into the carriers.

Second (or, third, I guess) is Ciamillo’s instructions leave a little to be desired. They could definitely use more detail. And that’s on Ted’s list, too. Using the steps here should get you on the road safely and enjoying the power they have to offer. Which is substantial.

And then there’s the weight. Calipers came in at 70g (rear) and 72g (front). If you had to use all of the hardware, you’d add 43g, but you won’t because he includes a short bolt and a long bolt to hold the carriers. Pick the appropriate one based on how many conical washer/spacers you need. (hint: narrower rims need more spacers). So, take away a few grams and you end up with a brake set that can be as light as ~155g.

Once installed and out on the road, my first impression was “Whoa! These things are powerful!” Their initial impact really sticks in my head. In fact, they’re probably the most powerful brakes I can remember using. It’s still early in the testing, so I can’t comment on durability, but I can honestly say they grab the rim firmly and with a linear feel that lets you modulate the force well.

Housing makes a difference, and I’ve been using standard shop-supply Shimano cable housing. Nothing special.

While the brakes make adjustment concessions for wider rims, they’re still built with racier tires in mind. Shown here, the clearance is getting into the danger zone with 25c tires on wide rims that push the rubber to 27mm wide. I haven’t had any issues, but 25c tires are probably the biggest I’d run with these.

Would I recommend them? Absolutely, especially at the new lower price. Yeah, they’re kind of tricky to set up, but I enjoy that sort of work. Take the hour or so and enjoy it. Bond with them. And your bike. Then ride like hell. Personally, I like seeing the little guy come up with something cool, and I’ve enjoyed hearing Ted’s story develop. It’s exciting to see him coming out the other end more resolved to make the brakes better and grow the business. And the cranks aren’t dead, but that’s a story for another time. And it’s a good story!

NOTE ABOUT COMMENTS:

Seriously, we know Ciamillo excites some opinions. This is not a customer service forum. Please feel free to discuss the brake’s performance, the company news or ask questions…Ted’s reading. Just know that we won’t tolerate meanness or any customer service issues will be deleted. If in doubt, check out Comments Policy.