The new Industry Nine Torch Road Alloy (TRA) wheels debuted just before Dirty Kanza 2018, and we had our hands on a set of the ULCX235 wheelset for a couple days of testing prior to the announcement. We rode them all over town, on dirt paths, and our usual rooty, gravelly cyclocross test track to see if they lived up to the hype. But first, we threw them on the scale and measured them, then checked in with I9’s VP Jacob McGahey to get the real development story behind the new wheels. Here’s the deal…

Torch Road Alloy development story

BIKERUMOR: What was the challenge in adding your direct pull threaded design to the Road Torch hubs?

JACOB: We actually made an alloy spoked road product way back in 2008-2009, however at the time, we were trying to address the aero needs of road riders and were using a bladed spoke with a nipple at the hub. It was a cumbersome system and hard to adjust, so we switched to more traditional bladed steel spokes in late 2009 and carried that forward with the Torch series road line-up. Now, with the gravel market taking off, aero isn’t as much of a concern as ride quality, so the timing was right. That’s where our alloy spokes shine – offering the precision and ride quality that our mtb. wheels are know for, which makes a lot of sense for gravel, and cyclocross, too.

This let us take advantage of the hub/spoke interface used in our mountain bike hubs. Threading the spokes into the hubs makes them easy to true because the spokes wind up much less than their steel counterparts. Other big advantages are steering precision…the wheels are much stiffer laterally, and torsionally, so you get a very direct power transfer. They’re also more durable. The spoke diameter is thicker than a steel spoke. Also, with steel spokes, the root diameter of the spoke threads is smaller than the base diameter of the spoke, which becomes the weakest point – particularly since the “V” shape at base of the thread forms a natural stress riser. It might take a few years before they fail, but eventually a steel spoke will break at the threads. Compare that with a 4, 5 or even 6 year life of our machined alloy spokes and you have a significant advantage. With our alloy spokes, we machine the threaded head larger than the rest of the spoke, and we roll the threads , so that weak point is gone. (NOTE: steel spokes have rolled threads, too, they’re just much smaller)

Customization is the other huge benefit. We offer eleven different color options for the hubs, spokes, and tubeless valves, so the possibilities for custimizing the wheels is almost limitless. Our Ano Lab lets you create something down to the individual spoke color, that matches your bike perfectly.

BIKERUMOR: What about aerodynamics? How do your thicker alloy spokes fair against thinner or even bladed steel spokes?

JACOB: We haven’t done any wind tunnel testing to show how they compare, but you are certainly going to give up some aerodynamic effieciency over a bladed steel spoke. We would probably include these the next time we do wind tunnel testing just to satisfy our curiosity, but the bottom line is that aerodynamics aren’t a huge factor for gravel or cross and the larger tires you’re likely to be running will shield the spokes from the wind as well.

The other small tradeoff is weight. This design adds about 30g of system weight compared to the steel spoked road Torch wheels. However most of the weight difference comes from the oversized flanges on the hub that are required to accept the oversized aluminum spokes. The effective rotating weight is within 10 grams of the steel spoke chassis.

The big thing I noticed when racing the steel spokes versus the alloy spokes back to back was the ability to just drop into a turn hard at speed, it’s amazing how much harder you can dive into turns when you have the extra stiffness in the wheelset.” (NOTE: Jacob races Cat2 Masters Cyclocross)

BIKERUMOR: What about stiffness? Are the alloy spokes as stiff as steel ones?

JACOB: The overall wheelset is stiffer. Part of this is because the spokes are thicker and have less elongation, but much of the stiffness gain is due to how the spokes are anchored at the hub. Since, the spoke thread directly into the hub there is no pivot at the anchoring point in the hub as there is with a steel spoke (whether straight pull or j-bend). Since the spokes feature a 50% thicker cross section than a steel spoke they are less flexible laterally as well which becomes a factor since they can’t pivot at the hub. It all adds up to improved lateral and torsional stiffness and a more connected ride feel.

BIKERUMOR: Doesn’t that make for a harsher wheel?

JACOB: The steel spoked wheels might have slightly more radial compliance. However radial compliance has more to do with the rim than the spokes. As the rim is deflecting, it’s actually relieving stress on the spokes, which is what’s going to add to compliance. That’s versus lateral or torsional forces that are trying to elongate the spokes. Because we use shallower, lightweight rims on these wheels, they’re going to offer more compliance than deeper aero rims you’d find on traditional road bike wheels.

BIKERUMOR: What about impact strength, like if a stick or rock got thrown in there?

JACOB: That’s hard to measure, but our failure rate on our alloy spokes is extremely low. I haven’t broken a single one in more than 10 years of racing and riding on them. Our alloy spokes are going to be stronger in terms of both impact and fatigue versus a steel spoke. The one area where a steel spoke might have a small advantage is with abrasion, so if you dropped your chain into your wheel, it might “saw” into the alloy spoke a bit easier, but that can happen to steel spokes, too.

BIKERUMOR: Are they stiff enough with straight pull, half spoke counts on non-drive/non-disc sides?

JACOB: The 2:1 lacing pattern has several benefits. You can build a laterally stiffer wheel, because you can locate the hub’s flange at a wider point on the non-drive side (rear) or non-rotor side (front). With two spokes on the side with less dish, and one on the wider side, we can actually use almost equal spoke tension. That lets us use lighter rims because they don’t have to be reinforced to handle uneven spoke tensions, and it reduces overall fatigue to the wheelset.

BIKERUMOR: Is the carbon rim made by Reynolds?

JACOB: Yes, most of our carbon rims are made by Reynolds, but are I9’s designs. However, we also use HED rims for some of our fat bike wheels.

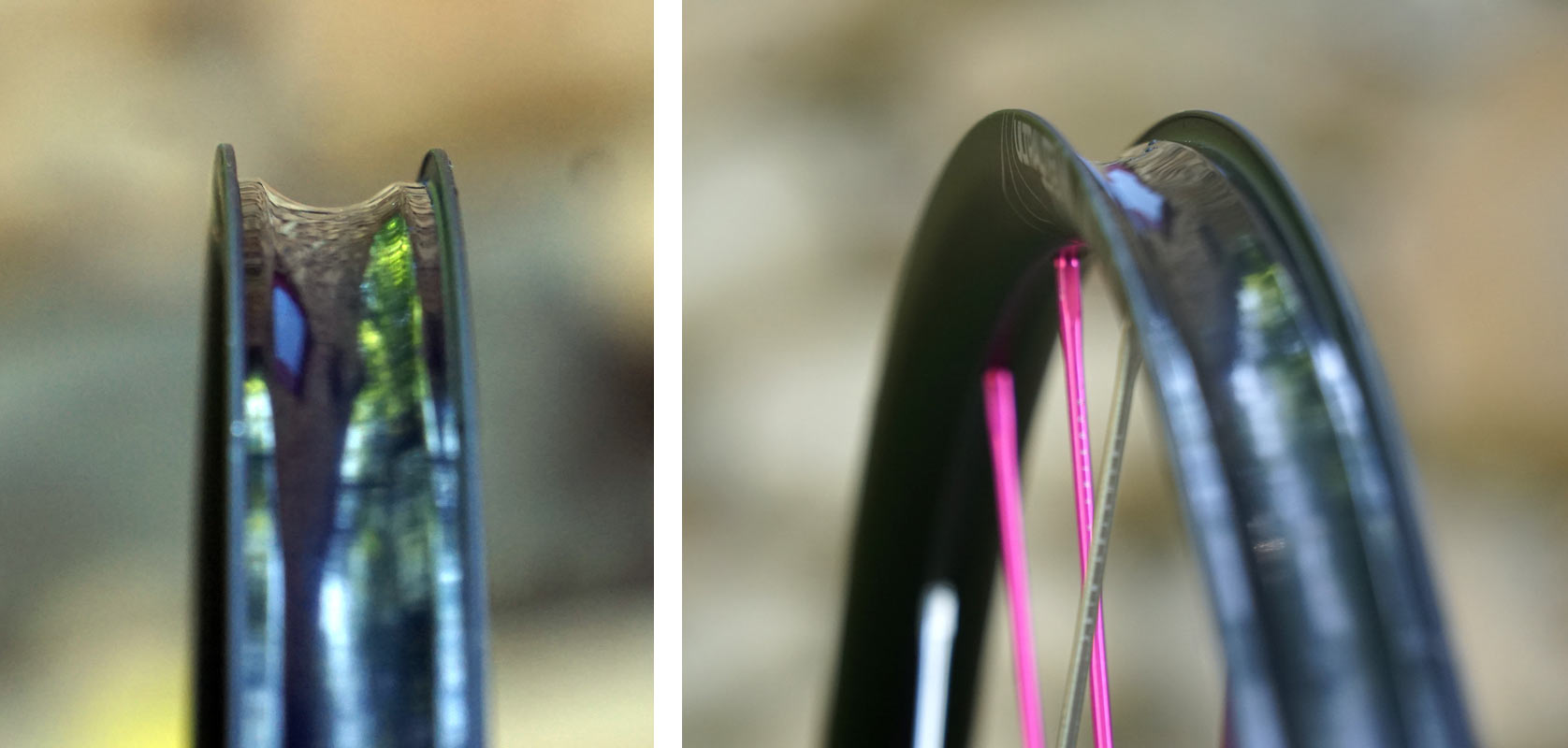

BIKERUMOR: Hooked or hookless? Why?

JACOB: We use hookless for our carbon mtb rims (and our ultralite CX rim) but all our carbon road wheels are hooked. We use hooked rims for anything that’s rated to run at 80psi or more to ensure tire retention at those higher pressures. For our hookless rims and our “dirt” specific profiles such as the Ultralite 235 we have reccomended max pressures depending on tire width. While we test to higher pressures than this, we feel customers will get the best riding experience if they follow the below guidlines for max pressure:

- 700 x 30-33 – 70 PSI

- 700 x 35-38 – 55 PSI

- 700 x 40-44 – 50 PSI

- 700 x 45-49 – 45 PSI

- 700 x 50-55 – 35 PSI

BIKERUMOR: How much more lateral stiffness does it provide over the UL alloy one?

JACOB: The carbon rim is laterally stiffer – Not hugely so, but it is certainly noticeable. We worked with Reynolds to build radial compliance into the rim as part of the layup schedule and rim profile, so it’ll be comparable to the alloy Ultralite rim in terms of comfort.

BIKERUMOR: The price difference between carbon and alloy models is about $1,000…We hear about some bike brands saying it’s actually less expensive or comparable to develop a carbon frame versus alloy any more, so is it really that much more expensive to produce carbon rims?

JACOB: It is. Our cost is at around 7-8x or more for a carbon rim versus an alloy rim. There are also additional setup charges, development time and other factors, too, beyond just the unit costs. Alloy rims, in contrast, do require a well-engineered profile, but the basic process of extruding material, rolling the rims, and then joining is less time intensive. With carbon, the raw material is much more expensive, but it is also much more labor intensive since each individual ply of carbon is laid into the mold by hand, and the rims require additional finish work vs alloy rims as well.

BIKERUMOR: The AR25 seems like it’s made for heavier riders or rougher conditions, yet it’s a narrower rim. Why?

JACOB: It’s more of an “all road” product that’s aimed at both pavement and dirt roads. It’s a product that works well for both road and gravel applications, whereas the Ultralight line of rims basically come from our mountain bike family, so it’s optimized for wider tires. The AR25 works just as well on a 23mm road tire as it will for a 45mm gravel tire, and it’s more suitable to bikepacking or touring thanks to thicker walls, deeper profile and overall more robust construction.

ULCX235 Actual Weights & Widths

Actual weights for the Industry Nine ULCX235 Torch Road Alloy wheels on our scale with QR endcaps was 667g front and 787g rear, for a total of 1,454g with rim tape and valve stems installed. Claimed weight is 1,395g (1,325g for carbon rims) with 12mm thru axles and no tape or valve stem. Jacob says a Shimano 11-speed FH body adds about 10g, rim tape 20g forth both wheels, and about 10g more for valve stems, so the balance is probably coming from the slightly heavier QR end caps.

We measured the rims at 27.5mm external and 24mm internal, which is 0.5mm wider than claimed for both measurements…which is OK by us.

First Ride Impressions

My usual gravel/cyclocross test loop recently received a fresh coating of mulch on a few sections, but mostly remained a solid mix of hard dirt, pea-sized gravel up to small rocks, a bit of slippery mud, and plenty of roots. I typically strike a balance in tire pressure that gives me good traction without feeling squirmy, which is never quite enough to avoid smashing the rim on high speed root impacts. I have managed to dent one of their Enduro alloy rims in the past (on far rockier, more aggressive bike park terrain), but so far, the Ultralight rims have held up to multiple cringe-worthy hits.

The wheels are impressively light, which is especially noticeable on the front end. Lifting the nose over obstacles is effortless, like it wants to float over them. Yet they’re as stiff as Jacob suggested during our Q&A. Tracking is spot on, even when the ground was trying to thwart my efforts to hold a line. Combine that with a good frame, and they kinda take away a lot of excuses. They also mean you really need to trust your tires, because they’ll encourage you to push them to their limits.

The light weight also benefits quick accelerations. Not so much an issue for gravel riding, but in cyclocross, it’s the name of the game. Popping up and over root sections like in the photo above became quicker and easier, with the sprint to the next hard turn or obstacle feeling just a little lighter, too.

It’s early in the test, and well before ‘cross season, but I’m confident these will end up being my go-to race wheels this fall. The combination of lightweight and performance-enhancing stiffness make these particular models a great price-per-gram-saved-and-benefit-gained upgrade. Step up to the carbon ones and you’ll get Industry Nine’s recently announced a lifetime warranty, too. Check out the complete new TRA collection here.