Spied throughout last year’s World Cup XC race season, the new SRAM Eagle AXS mountain bike group is officially here. It’s the first purpose built electronic mountain bike group with wireless shifting, borrowing the batteries from their road-going eTap groups, but that’s about all.

“We didn’t just take the road group and slap it on a mountain bike,” says product manager Chris Hilton. “Nor did we just slap a motor on the mechanical version. It’s bigger and tougher, and it’s not likely to be destroyed if you wreck. Physically, the pivots for the parallelograms are reinforced, and they had to grow to make room for the motor system. And that motor and gear box are both different than what’s in the road eTap derailleurs.”

What does carry over are all of the non-electric parts. Meaning, if you already have an Eagle group on your bike, you can add the AXS shifter and derailleur to it and it’ll work perfectly. The chain, cassette, cranks and chainrings are all the same. There are new XO1 and XX1 parts to go with the new groups, but they are only cosmetic changes (black/polar for XO1, and ti-nitride “rainbow” for XX1). Between the two groups, the only real difference is materials, which we’ve outlined in this post.

OK, so what makes them different?

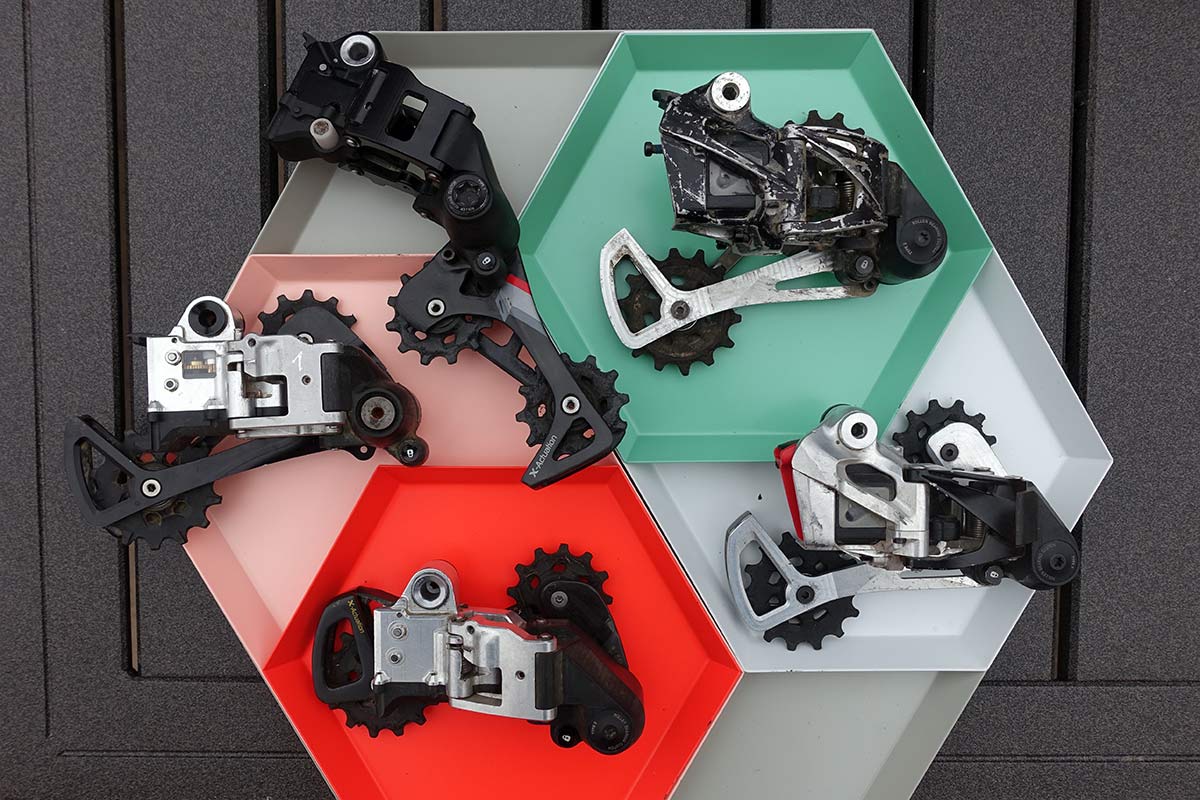

SRAM Eagle AXS development & prototypes

First off, it’s not Eagle eTap. “eTap” is for the road group, basically a play on the Double Tap shifting mechanism converted to electronic single taps. Along with the rest of their entire wireless-actuated product family, these simply get the AXS (read as “access”) moniker to differentiate them from the mechanical groups. You’ll still find a heirarchy in AXS, starting with the XX1 and X01 levels shown here.

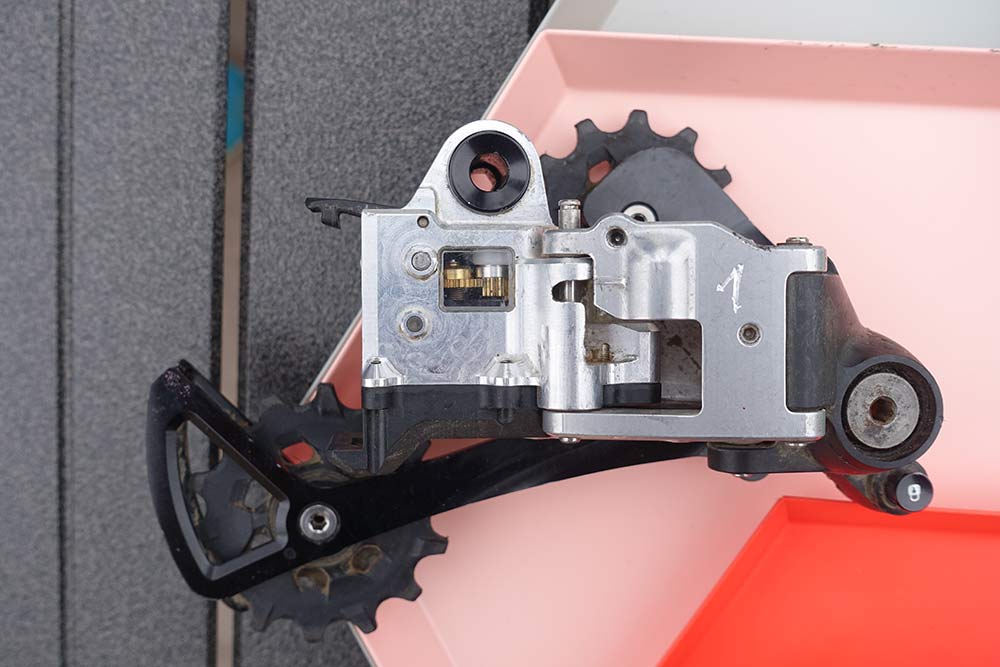

Now, about that derailleur. It’s entirely different, with some changes made for the obvious electronic/wireless features, but others made to improve overall shifting and drivetrain performance, too. Starting with the electronics, the main body of it had to grow to house the brain and gear box, and the battery sticks off the back. While it’s not meant to ever be disassembled, the entire electro-mechanical system is an enclosed unit protected by the metal exoskeleton.

Inside is a motor that turns at something like 80,000 rpm. So the gearbox steps that down to convert it from speed into torque. And there are a lot of gears in there, which is necessary to handle the changing loads as you shift. The torque requirements grow as you move to a bigger cog because it’s fighting against more spring tension from the pulley cage. So, while the gear box isn’t actually shifting those gears, it is designed to change its mechanical advantage ratio as you move up and down the cassette.

Between the gear cluster and the actuating arm is a clutch, which allows the parallelograms to safely breakaway in the event of impact. The clutch disconnects the gears from the arm for a second, then the derailleur automatically returns to its original position so you can keep riding. We’ll have video up in a separate post to show it in action, stay tuned.

Inside the “brain” are complete shift tables, so it knows where it is in space and how much it needs to move to create a shift. It’s adjusted via a small trim button on the shifter, and once you trim it into place for one gear, it’s perfectly aligned for all of the gears because trimming moves the entire shift table.

So, technically, the derailleur limit screws aren’t necessary. The derailleur itself knows where it is, but they’re there anyway as a safety precaution in case you damage it so it won’t throw the cage into the spokes.

The cage’s clutch has a slightly different configuration than the mechanical derailleurs of yore, but they’ll end up putting the new configuration on the mechanical units, too. It would be called Type 3.1 because it’s a slight reconfiguration of the Type 3, except that they don’t really call out changes to the clutches anymore, they just quietly roll them into production as they find ways to improve it. They’re not borrowing the new fluid clutch from the road group because this version is stronger, which works better for mountain biking…for now.

The geometry of the derailleur changed, moving the upper pulley forward and up. The actual cage length is the same, but this positional change had the effect of raising the lower pulley, too. The point was to gain ground clearance (it’s about 10mm better at its lowest point), but also to increase chain wrap on the cassette. It also positions the whole derailleur mechanism forward and under the chainstay more. It’s a bit more protected here, and can actually allow for a slightly shorter chain in some instances.

From a performance standpoint, the increased chain wrap means more precise shifting and engagement even when you have a lot of contamination (mud, grass, etc.). It’s also more precise because the upper pulley’s better able to guide the chain between cogs on the bottom without giving up engagement on the top of the cassette.

More wrap also means less wear, because more teeth on the cassette at any given time spreads the load across more teeth. So, each tooth is bearing a little less of the load, wearing slightly less. Same for the chain, so you should see overall improved component life.

Fun fact: The inner pulley cage plate is compatible with the plate from their mechanical rear derailleurs, so in a pinch you could pilfer parts off your old bike or derailleur…or just order a cheap replacement plate from SRAM (through your local bike shop, of course).

Eagle AXS wireless shifters

In comparison, the shifters are relatively simple. The wireless transmission protocol was figured out with the original eTap launch, and along with the addition of ANT+ and Bluetooth, it uses the same communication standard as the new AXS road eTap parts. Which is important to note because it means that all AXS-labeled parts are interchangeable. Want to add drop bar shifters and brakes to a monster-crosser with mountain cassette and rear derailleur? No problem. Want a speedy flat bar bike with a road group? You can do that, too. Heck, you can even replace these MTB shifters with a Blip Box and Blips buttons and just use those to shift your bike. And you can customize how all of it works together with the AXS app (check that post to see how it all comes together).

The body houses a CR2032 coin cell battery, transmitter and two switches. The paddle, or lever, is bolted to that, and the bolt doubles as the pivot point for the paddle rock up or down. All the paddle needs to do is make contact with the switches in order to initiate a switch, which means, technically, it can take on any shape they (or you, or a bike brand) wants. More on that in a minute. First, the development.

SRAM tested all manner of button, lever and paddle layouts to see what worked best, but they all shared essentially the same mechanism: two switch buttons, one for upshifts, and one for downshifts.

They even tried wireless GripShift style twist shifters, which only really had to twist a small amount. For now, these won’t be offered, but there’s no telling what could come in the future.

What they landed on was a sleek rocker panel that extends towards the front…

…which means you can position the shifter pod to favor pushing and pulling with the front nub, or using your thumb on the rocker panel in the back. Further down in this story we’ll discuss a few other options.

The bottom of the shifter has the pairing/trim button. Use that to set up the group and pair it to the rear derailleur, then hold it while pushing the shift paddle in either direction to trim the derailleur to fine tune shifting performance.

The result is an incredibly clean cockpit with only the brake lines visible. So, how’s it ride? Keep reading, we’ll get there, with links to our first ride review and more AXS content at the bottom of this post.

There’s an AXS app for that…

We have a full feature story on the AXS system and this app, and you can see it in action in the video for the new RED AXS road group, but here’s the nutshell version:

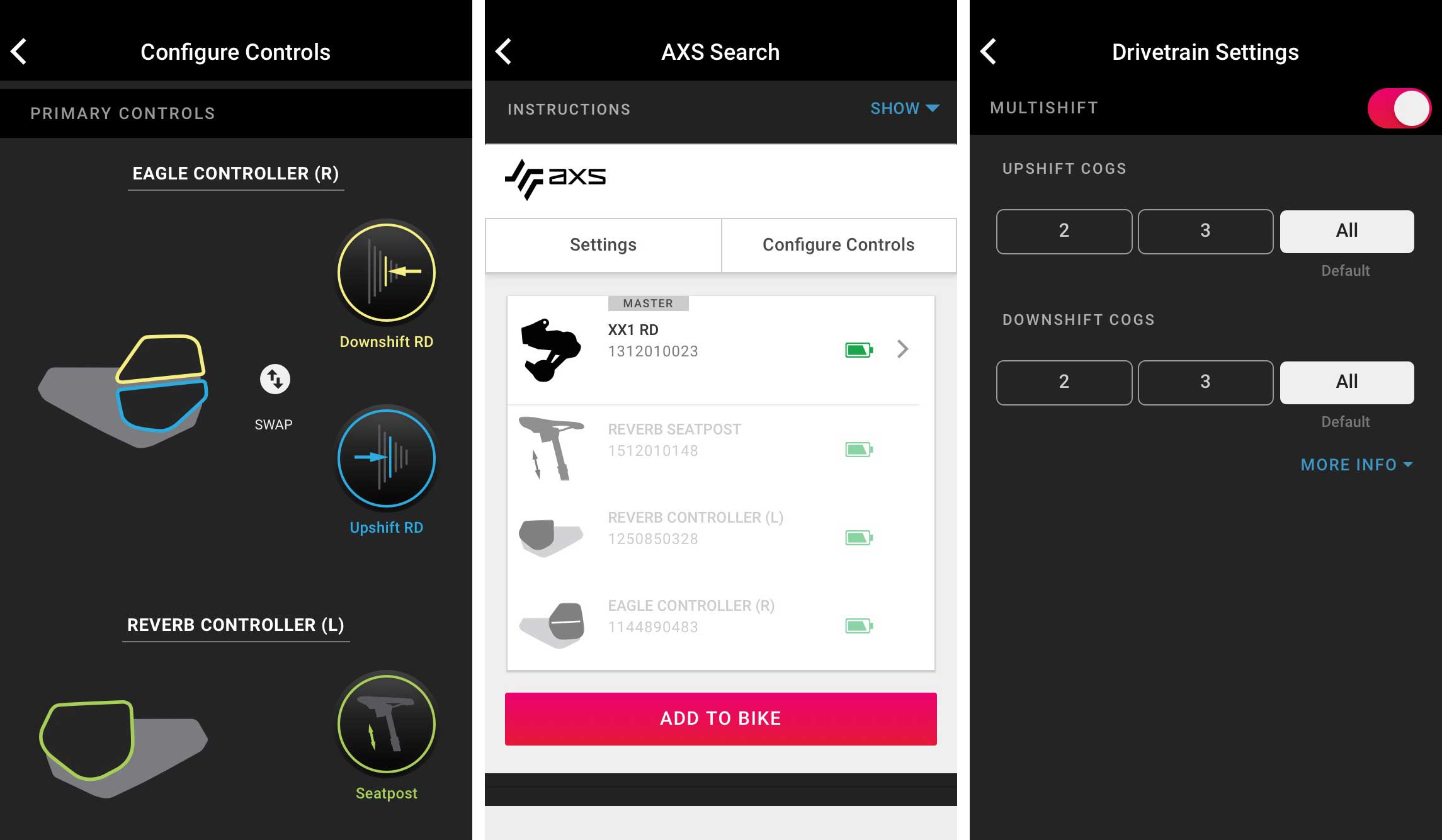

The AXS app is available for iOS and Android and lets you assign shift or other functions to specific AXS buttons. Reverse the shift pattern, or send upshifts over to a Reverb AXS remote and use one of the shifter’s “buttons” to drop your post. You can also turn multi-shift on and off. Or never download the app and just install the group and ride. SRAM didn’t want your enjoyment of the group to depend on an app, but the added functionality it offers lets you customize it to suit your needs.

Another cool feature is the app’s ability to show gear usage. The derailleur knows how much time is spent in each gear and will sync that data with the app. Eventually, it may offer alerts or service reminders based on mileage, but at a minimum you can use the data to see if a smaller or larger chainring might make you more efficient. Other features are likely to come in the future, but rest assured no one can download the app and use it to control your shifting…it can’t shift the system, it can only change button settings. And you need to pair the parts with your app, and they can only be paired to one thing at a time…so unless they have your phone, they can’t mess with your system. Lastly, you don’t have to create an account if you don’t care about saving any settings, so you can remain totally anonymous to SRAM if you want.

Other things you should know

The battery is good for 20 hours of riding, and recharges in just one hour. Because it’s the same as all other AXS components, you could borrow the battery from your Reverb AXS or road AXS group in a pinch. Or just carry a spare, they’re only 25g. You can check battery life by pressing the button on the derailleur. Green means good to go, red means about half a charge, and blinking red means almost dead. The shifter’s battery, however, should be good for up to two years of riding.

The group is waterproof up to the IP69K standard, which means you’re unlikely to hurt it even with the occasional pressure washing (because we all know we do it sometimes, and pro mechanics do it a lot). So, rainy days, stream crossings and the like are no big deal.

The XX1 group now comes in “Rainbow” color, which is actually a similar Ti-Nitride finish as the original gold, just not as obnoxious.

While the chains for this and the new road group are both 12-speed, they are different dimensions and are not cross-compatible.

Aftermarket groups will ship with 32-tooth chainrings for XO1 and 34-tooth chainrings for XX1. All of the usual other sizes are still available, and the cranks are only available with DUB-sized spindles, so you’ll need a compatible bottom bracket.

SRAM Eagle AXS Hacks & Prototypes

Too soon?

Not really, no. And throughout the launch event SRAM’s team was very open about the fact that they had a really hard time deciding on the final button layout for the shifter. Apparently, one of the few things that was harder was actually getting all departments to agree on the AXS name.

They also admit that they full expect third parties, bike companies and even regular riders to come up with alternate button arrangements that’ll bolt to the stock shifter pod. The images above and below were on one employee’s bike that served as a test mule, and he (unofficially, of course) preferred this button layout. Personally, so did I after trying it out.

The rear rocker panel sits much further inboard, and the front nub has a more useable paddle that could be better grabbed with your pointer finger. So, got a 3D printer and some skills? Time to start a side hustle…

We also spotted this battery cover on another bike. They wouldn’t tell us anything about it, but it was very securely held in place and is likely there for additional impact protection. It snapped on using different attachment points than the battery itself, so if it did get knocked off, it didn’t seem like it would take the battery with it.

Want an all AXS pass?

We’re covering the entire SRAM AXS launch in multi parts, here’s the rest: