The new Industry Nine 1/1 hubs had the unfortunate situation of being launched on the same day as their shiny new Hydra hubs. The Hydra feature set captivated us, and the 1/1 sort of ended up overshadowed. Then I9 launched the 1/1 wheelsets, giving them (and you) a complete wheelset with options for just $750. It’s a bargain, and you can choose from Trail or Enduro rims, plenty of axle configurations, and black. Or black.

Here’s our test of the 1/1 Trail Wheels, showing how a premium brand can “down spec” their offerings to lower price points yet still deliver features well above average…

Quick note: The hubs and wheels were originally called 101, but a trademark issue made them change the name to simply “1/1”. OK, here’s the review…

How do they compare? Why are they less expensive?

With a $225 spread between the new “entry” level I9 1/1 hubs and the much higher end Hydra hubs, one may wonder: Where do the 1/1 hubs skimp?

Fortunately, in very few places. And to explain why, we need to explain how the 1/1 hubs are actually an upgrade from the outgoing Torch hubs. The difference between Torch and their new entry level 1/1 hubs has to do with improved durability and performance. The 1/1 has six pawls, phased such that only three are engaged at any given time. As a general rule, pawl-and-ratchet hubs have the potential to end up in a situation where there’s just a single pawl engaged under high torque loads. These loads flex the hub, as do impact forces, leaning forces from the bike, etc. And, I9’s VP Jacob McGahey says, these situations happen fairly frequently, and it will continue for as long as you’re pedaling and applying pressure to the system.

To counter that, I9 increased the bearing size to increase the load capacity and better handle torque loads. You can see the difference in the photo above – new bearings on the left, Torch on the right.

Not visible in that photo, they also increased the diameter of the pawl pocket, from 4mm up to 5mm (Side note: The “pawl pocket” is the round space where the round end of the pawl is captured inside the freehub body. Torch was 4mm, as is Hydra, but the 1/1 hubs get larger pawl pockets). So the pawl sits more securely with a larger base inside the inner part of the freehub body. All of which means less deformation, which means when you do have single-pawl engagement instances, they’re less likely to wear things down internally.

To further resist torsional flex, they went to a larger diameter drive ring, which reduces the cantilevered forces and peak loads in the system. In other words, less load on each tooth, and even less likelihood of single-pawl engagement scenarios.

As for Hydra vs. 1/1, the biggest difference is in the points of engagement. Hydra has 690 for 0.54º rotation. 1/1 has 90 POE for 4º rotation. So, technically, there are only 45 teeth on the drive ring, but the phased sets of pawls effectively double that to 90.

But wait, there’s more…

Industry Nine is machining the hubshell out of blank material in house, same as Torch and Hydra, but with a simplified profile to make them a little quicker to get in and out of the mills. The drive ring is broached in a multipart process, some of it done at a third party (but still in the USA), some done in house.

The pawls start as an extruded profile that is machined, tumbled and de-burred, heat treated and then media blasted in house to take on their final form. The drive ring is cut on a lathe, broached, heat treated, then media blasted.

That’s in contrast to the EDM wire cutting used to create the Hydra/Torch drive ring and pawls. The EDM takes longer and is more expensive, but it can deliver extremely high tolerances and cut a harder material…which is important when you need a harder, already-heat-treated steel and are cutting 115 minuscule teeth. That’s more than double the 45 teeth on the 1/1 drive ring.

Another cost savings comes from the freehub bodies. The 1/1 parts from a forged stock, then is finished with machining in house. The Hydra/Road Torch starts as raw stock cut into blanks then machined into shape. The 1/1 freehub is just slightly heavier, mainly due to a difference in materials between the two…the Hydra requires smaller parts, which mean higher load-bearing capacity, so they use a harder material.

The other difference is in finishing. The 1/1 hubs come out of the machine shop, get cleaned, then go straight to anodization (check that video to see the difference). And you can only get them in black. The Hydra hubs get additional polishing before ano, and you can get them in a rainbow of colors, all of which (including black) will be shinier than the non-polished 1/1 hubs. Lastly, the 1/1 hubs are only available with standard flanges for J-bend spokes.

So, are they “cheap”? No. At least in terms of quality. Industry Nine looked at competing hubs in that price category and wanted something that would be durable for the long haul.

Tech specs & actual weights

The 1/1 wheels are available with either Trail (tested) or Enduro rims. The “S” on the rim refers to “Steel” spokes, as opposed to their house-made alloy straight pull spokes for the Hydra wheels.

The front only offers 110×15 Boost hub spacing, but you have your choice of 12×148 Boost or 12×157 Superboost. Wheels are built using 28 Sapim steel J-bend spokes, laced 3-cross.

All of them are available with 6-bolt brake rotor mounts, and the standard Boost versions are also available in Centerlock (sorry, no Centerlock option for Superboost).

You also have your choice of HG (standard Shimano 10-11 speed), XD (SRAM) or Microspline (Shimano 12-speed) freehub bodies.

Inside are the six pawls, offset so three are engaged at a time.

The new seal design means that if you pop the freehub body out for service or swapping, you’ll need to then pop that rubber seal out before reinstalling the FH. Once you replace the FH, then slide that seal over it and pop it back into place. Otherwise, the lip gets trapped inside and creates drag.

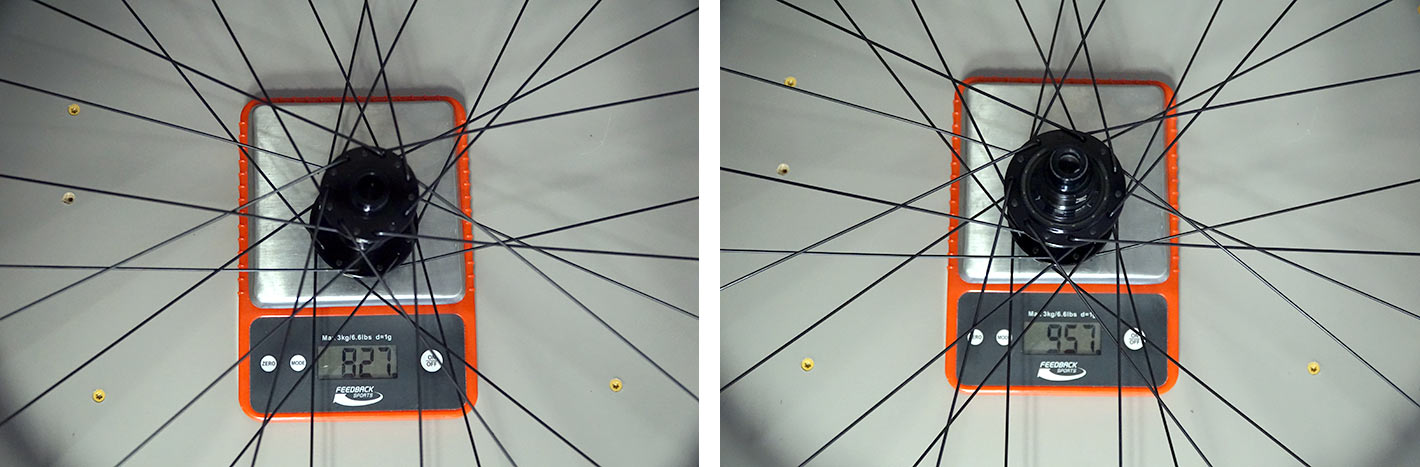

The Industry Nine 1/1 Trail S 29er wheels’ actual weight is 827g (front) and 957g (rear), or 1,784g for the pair, with tape and valve stems pre-installed.

Claimed weights are 820g/950g, so we’re pretty close. Claimed rim weight is 455g. (They also come in 27.5 sizes, with claimed weights of 760g/890g/430g)

Industry Nine recommends tire widths between 2.2″ and 2.5″ and a max rider weight of 230lb (104kg).

The internal rim bed is shaped with a tire bead perch and catch to hold them tight once seated. There’s a small hook at the top of the wall.

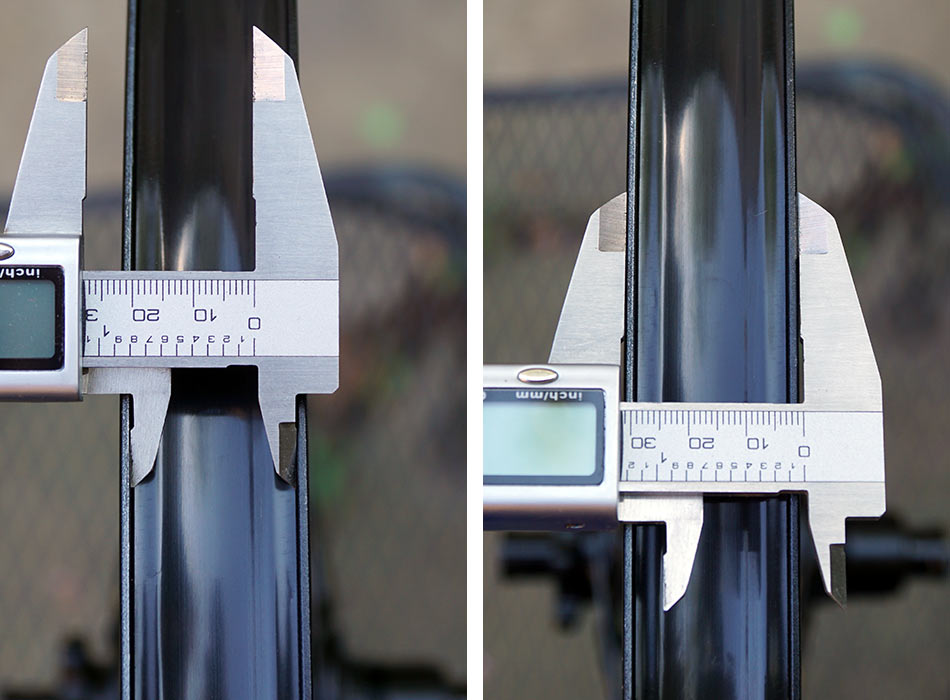

Internal width measured right at the claimed 27mm, and external a hair over the claimed 30mm (about 30.4mm on our calipers). They come with a 2-year warranty.

How do the I9 1/1 Trail Wheels ride?

Pretty darn good. If you’re familiar with I9’s performance, these will feel basically the same or better than what you had with Torch…save for a slightly slower engagement rate. They have all of the same bearing and axle upgrades as Hydra, so they’re stiffer and more durable. I could flick them around without incident, and they spool up quickly out off the line.

Most importantly for I9 fans, they sound the same. That loud, borderline obnoxious Industry Nine coasting scream is still there. Now you can sound like you’ve spent hundreds more!

At $425, the 1/1 hubset isn’t exactly cheap. But at $750, the 1/1 Trail Wheelset is. Basically, you’re getting a complete wheelset for just $100 more than the cost of a set of Hydra hubs. And the 1/1 Trail wheelset performed flawlessly on our local trails. Given our past experience with I9’s alloy rims, we suspect these will hold up for the long haul, too. While we haven’t dinged these, we have dented some of their other alloy rims in the past, but without incident – no loss of pressure, no early fatigue, no problems, even after lots more abuse.