We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. Hit the link at the bottom of the post to submit your own question.

Merry Christmas, folks! Welcome back to the Bikerumor Ask A Stupid Question series. This week we have a really interesting question from a reader about custom shock tuning. We often see mountain bike brands make a big deal of their custom shock tune in their press releases, but what does that actually mean, and how do they decide on which specific damper tune is best for their bikes? We went to mountain bike brands and suspension manufacturers in a bid to find out a bit more about the shock tune development process from both sides of the equation. Your expert contributors this week are as follows:

- Ken Perras, Rocky Mountain Product Manager

- Adam Miller, Owner and Frame Designer at Revel Bikes

- Jochen Forstmann, Founder and Co-Owner of LAST, General Manager and Head of R&D

- Matt Hornland, PR & Marketing Content at FOX

- Sofia Porfirio, Head of Marketing at Formula

Custom Shock Tuning from the Frame Designer’s Perspective

Rocky Mountain: We start the process by sharing suspension rate information with our suspension suppliers. This allows them to develop damper tunes that they feel would be best suited to our kinematic, and serves as the starting point in the shock tuning process. The next step can vary depending on the type of frame development.

In the event that the suspension or shock platform is all new, and previous tunes and ride experiences do not carry over, we typically set up a comprehensive tuning session, that can span days if not weeks. This allows us to test a wide range of tunes and setups to determine an optimal tune that we feel best suits the intended use of the suspension design. This process also encompasses the different tunes we offer on some frame sizes, or helps validate the use of the same tune on the different kinematics we offer on our smaller sizes.

After that initial test session, more riding is performed on the new frames and shocks to validate the settings we achieved. Sometimes we need to make adjustments with the suspension supplier. This can be due to factors such as testing in new terrain or in different weather; hot/cold temps and extreme conditions such as dry, hard pack or muddy terrain can make it difficult to achieve our initial goals. In other cases the supplier has made internal hardware updates that could affect the shock tune, so we need to revisit the settings to ensure they are still applicable.

Finally, after the testing period, we need to settle on tunes and have part numbers created for orders. This doesn’t necessarily mean that shock tuning is over as we can gain new insight with more ride time, and apply that knowledge to the following product year. We are constantly evaluating our tunes and collecting feedback from our staff, customers, race team, etc., to ensure that we have the most optimal tune we can get. The work is never done!

Revel Bikes: This is actually a fantastic question! This part of the bike development process is often overlooked or not talked about much, but it is one of the most important. If you get a perfectly designed full suspension bike but with a shock that is not tuned properly, you might as well have saved all your money and stuck with a hardtail in the first place.

Generally, when we design a bike, we start with the geometry, desired suspension travel, and different frame features. Then we work with Chris Canfield to lay out the suspension kinematics, and that’s where a lot of the magic happens. Once we’ve got those dialed, we send a leverage curve to our suspension suppliers, and they take their best guess at the proper tune for the bike.

By the time we get rideable prototypes, we get to do the most fun part of new bike development and test ride them like crazy. I could talk for hours about our ride testing processes and how we do blind testing with different carbon layups and shock tunes and secret ride test feedback forms with a curated group of riders from within our company and out of it, but we can save that for another discussion… the bottom line is we make sure that the shock manufacturer’s best guess is correct.

We’ll generally try some tunes outside the ones that they recommend, too, so we can be extra confident that the shock we’re bolting on our bike makes the suspension perform to the best of its abilities for the widest range of riders and terrain. Since we’re lucky enough to have crazy technical Sedona-style trails a couple hundred yards from our office at Red Hill here in Carbondale, we can do a whole lot of good ride testing really easily.

The only downside of our location is we get a whole lot of snow in the winter, so if the development timeline and shock tune testing falls during the winter months, we usually make a trip to Grand Junction or Moab and try to ride several different types of terrain on those shocks. The supply chain challenges and parts shortages have affected even this aspect of bike development- in the past, it was easy to order 10 or more shocks with different tunes from different manufacturers and try them all out at once.

Now, since fewer shocks are available, we have to be a lot more confident up front and only order a few different shocks. Luckily, after a few years and several CBF bike models and Chris Canfield’s suspension expertise, we’ve gotten pretty good at nailing shock tunes on the first or second try. Also, if bike manufacturers recommend a certain tune for a shock, I definitely recommend following that advice and not trying something different – the bike will usually ride much better! Overall, shock tune testing is super fun and it makes for a good excuse to get a few extra lunchtime product test rides in.

LAST: Deciding which shock tune is the best for a certain bike is a hard one, especially when starting from scratch. Fortunately that’s almost never necessary because everyone is evolving their portfolio of shocks and we are evolving our frames incrementally as well. Even if frame designs might look totally different, they carry over a lot of the kinematic principles.

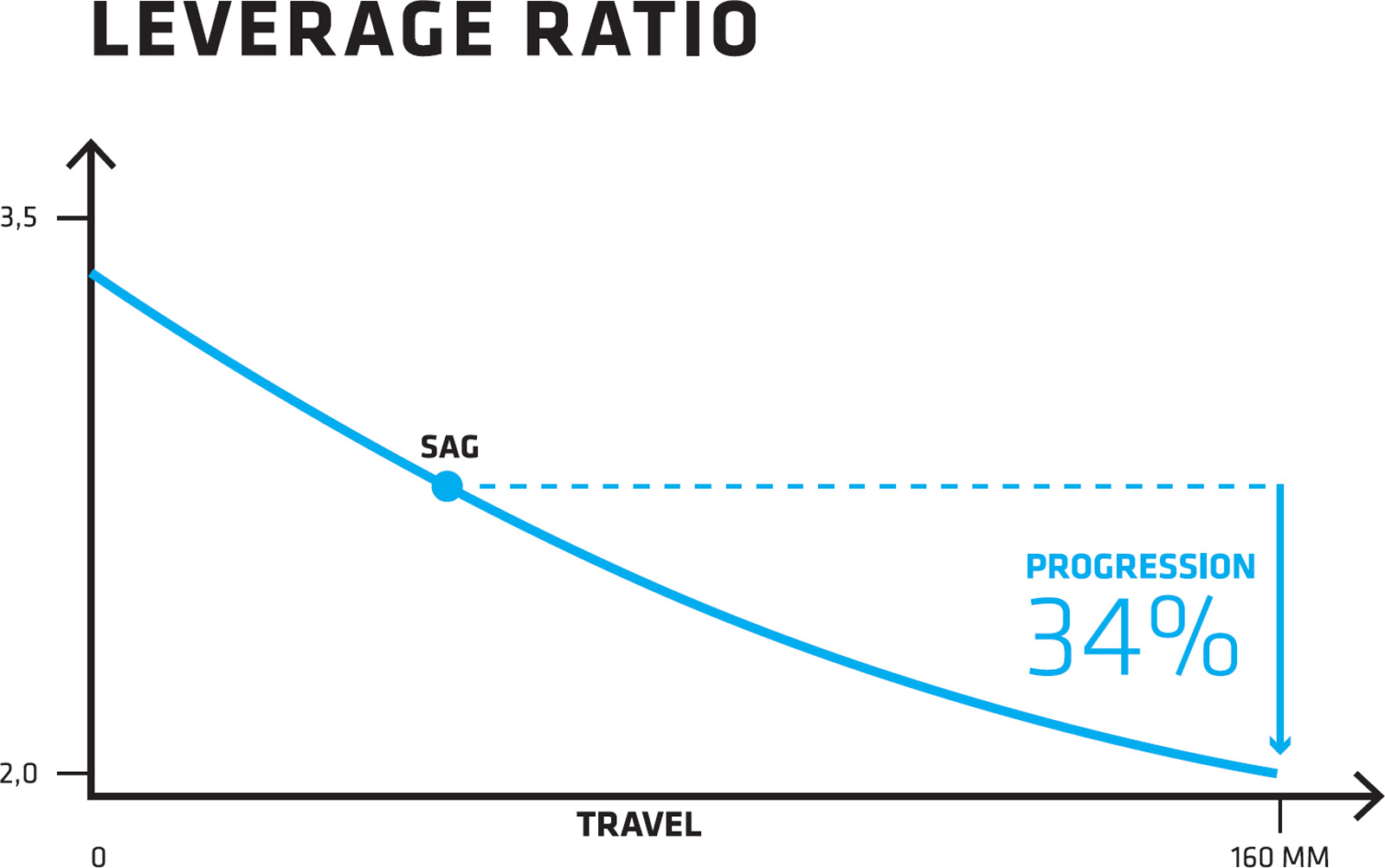

At LAST we like very progressive kinematics. Each of our frames is really progressive, with small alternations for the intended purpose. This shows in the leverage ratio curves. Note that we measure progression from the sag point and not from the start of travel. The leverage ratio curve is the starting point and most valuable asset available before testing. You can rebuild shocks while testing with the shock OEM, but prior to testing potential tunes are identified and prepared. And not all testing is done in presence of the shock OEM.

From the leverage ratio curve you can learn if your kinematics leverage ratio is kind of normal or not. If you have a fairly high leverage ratio more damping may be necessary. Damping forces depend on the displacement speed of the shock shaft. High leverage ratio numbers result in slow shaft speeds, and thus firmer damping tunes.

The leverage ratio curve also helps you to decide between air volume options. Positive and negative air volumes and their ratios affect the behavior of air springs and need to be specified. This means in most cases we can select a configuration of tokens that is installed in the shock. We believe that excessive use of tokens is not the way to go. Coil shocks and air shocks feel different, but their springs should have similar characteristics if used in the same frame. Making an air shock further progressive with many tokens is not necessary if the frame kinematics are progressive enough.

Testing includes a mix of riders that we know very well, including myself, riding the different options. We like to test on our home trails, at least in addition to more testing convenient bike park tracks, because we know our home tracks well. It helps a little with the difficult task of comparing stuff that might not be available at the same time. The testing can lead to a loop of modifying and continued testing until we are happy with the result.

We have some electronic measurement devices that help to evaluate certain aspects. They can be used to set sag exactly and and in a repeatable manner, notice how much travel is used etc. But we are far from letting these tools make the decisions. We are focused on providing a responsive feeling bike that let’s you enjoy each ride.

Summing up, before the first ride, both the shock maker and we have chats where we discuss ideas and learn about the new offers. The start for real life testing is an educated guess that both sides agree on, with us taking final responsibility for the testing and selection.

Custom Shock Tuning from the Suspension Manufacturer’s Perspective

FOX: Our FOX Factory OE Suspension Tuning Group works directly with frame engineers, designers, and product managers to realize the optimum suspension setups for our OE partner builds. The work of creating these setups can mean developing new bike specific damping forces, finding the sweet spot for existing product, and sometimes developing new product to meet the needs of desired end-user group. For those familiar with the Dialed YouTube series, OE tuning camps can resemble trackside at WC race events: meticulous lap testing, rider feedback, adjustments, tear-downs, rebuilds and doing it again.

FOX suspension is incredibly tunable, and the magic comes in finding the blend of meeting the frame dynamics, the intended riding category, and the expected user riding style. As suspension is an integral component in the design of the bicycle, we want the end-user experience to be smooth off the showroom floor. We also build our shocks and forks to have room for personal customization in the form of adjustable compression and rebound settings, volume spacers, and even additional valving and tune options down the line if a rider would benefit from changes.

Formula: So for the rear shock, this is how we do it:

Before the pandemic, and as we were starting with our very first MTB rear shock, we asked our customers (the frame manufacturers) to provide us with the leverage ratio and all the specifications, but also to give us some time with the frame in house at the Formula Factory to allow us to conduct internal testing before sending the shock back to the Bicycle Brand for a test session.

During the pandemic, as it was impossible to move, we asked to the brands to send Leverage Ratio information and a complete test bike. Our engineers do the setup and testing before it is sent back to the brand for them to do tests of their own. Sometimes it works directly and sometimes they needed to play with the CTS on their own to adapt the setup as they want.

Nowadays, we have developed our base tune to be able the use the CTS technology as much as possible. The idea is (if the pandemic situation is under control in the EU) is to organize the test setup in the terrain always based on the leverage ratio of the frames for the basic setup and to play with the CTS to find the perfect match.

We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. Hit the link at the bottom of the post to submit your own question.