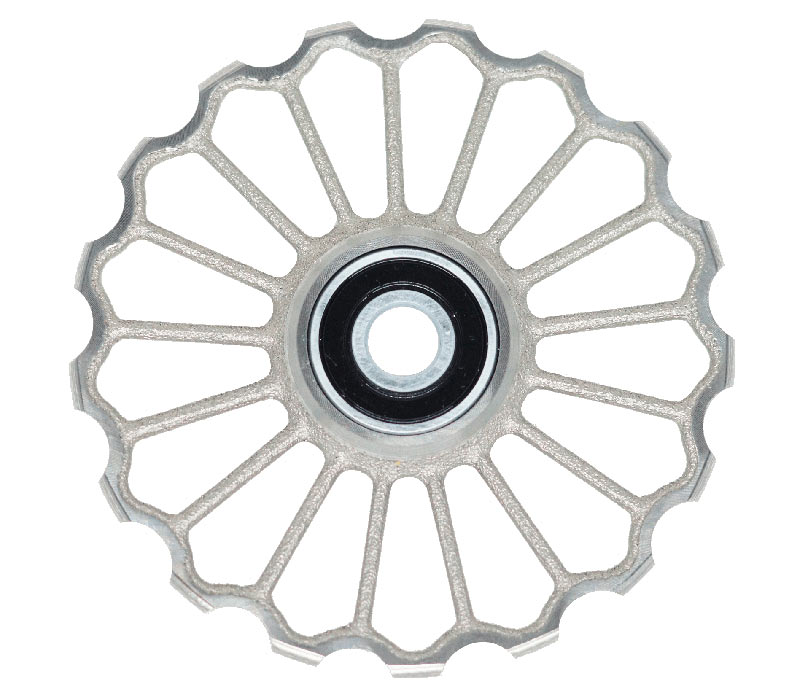

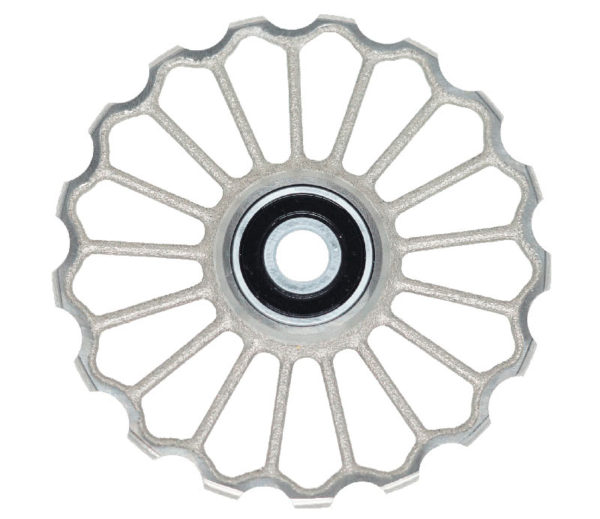

Shown aboard this custom titanium Mosaic Cycles road bike featuring ENVE fork, wheels and cockpit were the new CeramicSpeed OSPW titanium derailleur pulley wheel upgrade and Outboard Headset.

This isn’t their first effort to 3D print titanium pulley wheels, but it’s definitely their most expensive. Two years ago they showed the first iteration, which were sized like traditional jockey wheels but hollow. Then they launched the first OSPW system with oversized alloy wheels later in 2015 that had several bearing options.

Now, it’s been upgraded to be lighter and using a shape inspired by nature…

Resembling the Danish national flower, the Marguerite Daisy, the design holds the 18-tooth ring on hollow spindles leading to a core with their ceramic bearings. They say it’s 10% lighter than alloy wheel, but twice as durable. Priced at $1,700 (€1,500) it’s meant to be a showcase of the no-holds-barred technology they’re capable of.

The wheels are compatible with the existing OSPW cage, which replaces the stock derailleur cage. It’s shown here with a fresh new UFO coated chain.

They’ve also introduced a new outboard variant to fit bicycle frames with a 44mm headtube, which is what many handmade/custom bike builders are using these days because of the versatility it offers in fork and headset selection. As shown, it made for 1-1/4″ to 1-1/8″ tapered forks, which are used more for road (so, no, you probably wouldn’t wanna put this on your mountain bike). Additional sizes will follow.

It gets the same CeramicSpeed bearings and alloy cups as their other headsets, just in a new size. Retail is $389 (€299).