Japanese brand Gokiso has added to their remarkably smooth micro suspension hubs, creating their own carbon fiber clincher road rims built into complete wheels.

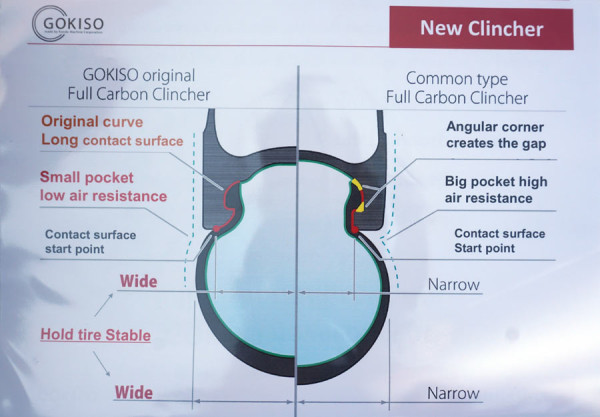

The combination results in something they claim has extremely low inertia, requiring just 0.5g of force to start them rolling. That means they’ll spool up faster for quick acceleration and less effort to keep them rolling fast. Part of their ongoing energy savings comes from a unique inner bead shape that brings the tire much closer to the edge of the rim and creates a wide, stable tire shape.

Check it out, along with some new hubs and an absolutely gorgeous titanium bicycle from a partner brand…

Notice the minuscule gap between the edge of the rim and the tire? That’s by design, helping smooth air flow. But that’s just one of the benefits:

The rims’ unique bead socket shape is CNC’d in their own factory in Japan. On the inside, it’s shaped to completely trap the tire bead with no gaps. On the top, it’s curved to provide a smoother transition off the rim, which they say gives the tire a wider, more naturally round shape to improve stability. If true, we’d say it should also improve handling by making cornering more predictable.

They also say it creates a shorter (but slightly wider) contact patch with the ground, which results in lower rolling resistance.

A closer look on two different rim depths.

The rims will come in 29mm (480g), 38mm (500g), and 50mm (530g) depths, sold as complete wheels. The braking surface has a basalt layer to improve friction.

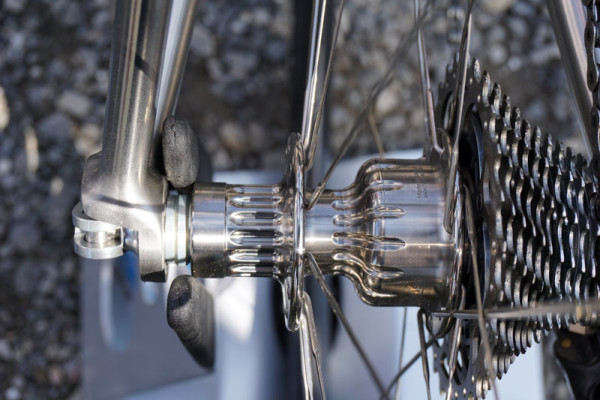

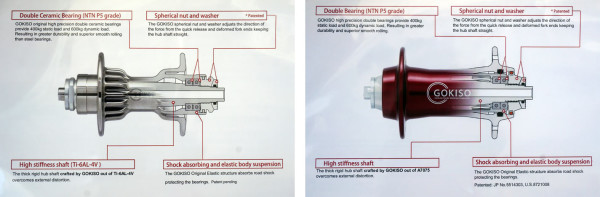

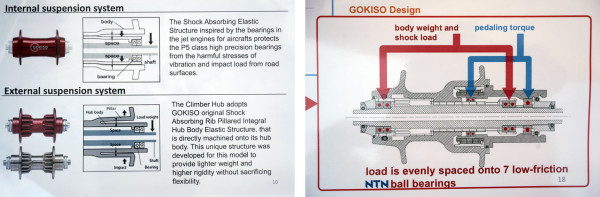

For the hubs, we covered their technology a couple years ago in great detail and with videos, but the short of it is that the ribs suspend the spoke flanges and allow for micro movements. Internally, a slotted sleeve acts like a leaf spring to add a tiny bit more movement, all while keeping the hub adequately stiff. Hit that link above to see it in action, it’s worth it.

At the top of the line are these titanium-shelled Super Climber hubs. They’re not the lightest ones they make, but they use more and finer ridges on the front and, well, they’re titanium. Weights are approximately 240g front and 450g rear.

Notice how the spoke flange floats above the rest of the hub shell. Each of the supporting ridges acts like an external leaf spring, and that’s just phase one of the suspension.

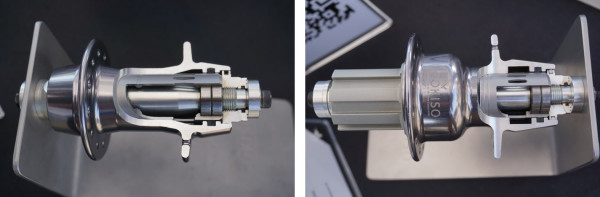

The aluminum shelled Climber hubs come in at about 190g front and 400g rear. Not light by modern standards, but there’s a lot going on inside them:

Click to enlarge and you’ll see the cylinder inside with slots. The outer hub shell only contacts this cylinder in the middle, letting the material left between the slots act as small leaf springs to provide a bit more suspension. The design separates any suspension movement from the bearings, so it doesn’t affect how smooth they roll. And thanks to very high grade ceramic bearings, they do indeed roll very, very smoothly.

The design splits the freehub body’s bearings, putting a hub axle support bearing between them, which spreads the load as wide as possible to reduce flex.

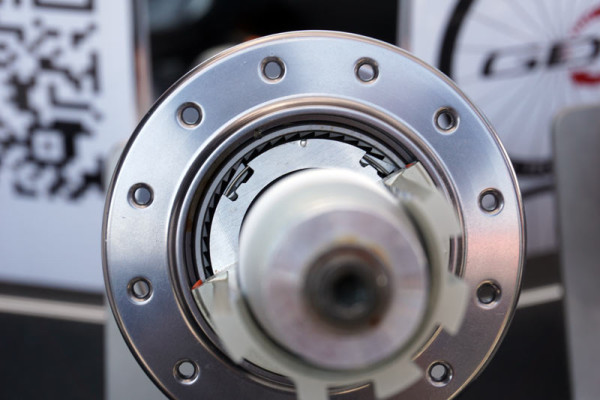

Top all that off with 92 teeth and alternating engagement (see how that pawl on the left sits between teeth? Two pawls are engaged at any given time, the other two just half a step off. That makes for very quick engagement, and since the pawls are twice as wide as normal ones, there’s plenty of contact to carry the load.

They also make internally suspended hubs. While they don’t look like the external ones above, the outer sections of the hub shell are also suspended over the axle, sitting on the inner cylinder only in the thinner center section. All of their hubs use a reinforced inner axle to support all of the micro movement without flexing.

Gokiso formed a relationship with Passoni bicycles and used their frames to demo the wheels. This one in particular stood out for its amazing craftsmanship.

Fluidly smooth welds drew us in, then details like the brake cable ports kept us hunting.

A small guide integrated into the derailleur hanger catches and hides an EPS/Di2 wire, keeping it from jutting out sideways or getting in the way of the quick release during wheel changes.

A little further reading on the hubs, click to enlarge. And check out their website for videos and more.