Mountain bikes have changed. Every improvement to the modern MTB is letting more riders go bigger and faster. Simultaneously, ebikes are experiencing similar evolution, only with more abuse to the drivetrains. All of this puts a tremendous amount of strain on your hubs–the unsung heroes keeping your bike rolling on the trail.

When Industry Nine launched the Hydra platform six years ago, it was a massive improvement over their Torch platform in terms of engagement. Pre-2020, it seemed that brands were still vying for the top engagement spot and the 690 points of engagement for the Hydra made the industry take notice.

If you’ve ever met the Industry Nine team or had the chance to tour their factory in Asheville, North Carolina, you know that they thrive on precision. And the pursuit of perfection. They claim to have over 100,000 Hydra hubs in global use, and they’ve taken all of the feedback from riders across the globe to heart.

“Our goal with Hydra2 was to create a hub that could endure the most extreme conditions and the most demanding riders,” said Jacob McGahey, VP and Head of Product Development at Industry Nine. “By leveraging lab testing, real-world data, and our in-house engineering and manufacturing resources, we’ve achieved a hub that sets a new standard.”

Just what does “a new standard” mean for Industry Nine? It’s a hub that is better in almost every metric while keeping it within a few grams of the original Hydra.

Key improvements:

- Enhanced Axle Strength: A 65% thicker axle engineered for superior stress dissipation.

- Increased Bearing Longevity: Larger 6903 bearings throughout the hub, a new labyrinth channel, and full-contact radial lip seals on the freehub and endcaps for unparalleled protection against contaminants.

- Consistent Bearing Preload: A foolproof design maintains peak bearing performance, regardless of axle tightness.

- Reinforced Pawl Engagement: Larger 5.5mm pawl pockets, providing 26% improved force dissipation to prevent wear and tear.

- Improved Drivetrain Durability: Tougher metal for the drive ring and an additional tooth on each pawl, specifically designed to handle the high torque demands of powerful E-bike motors.

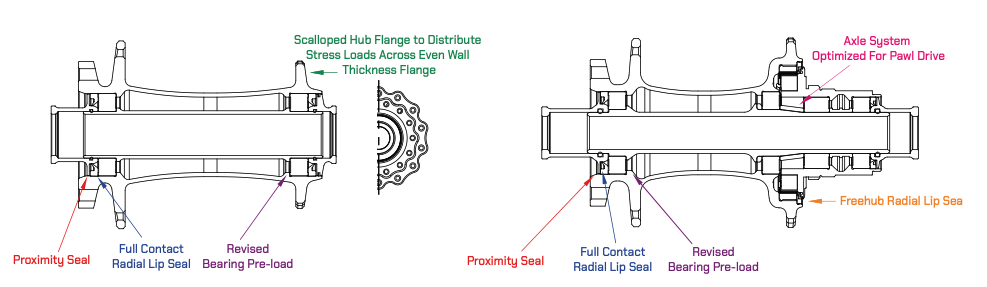

New Scalloped Hubshell

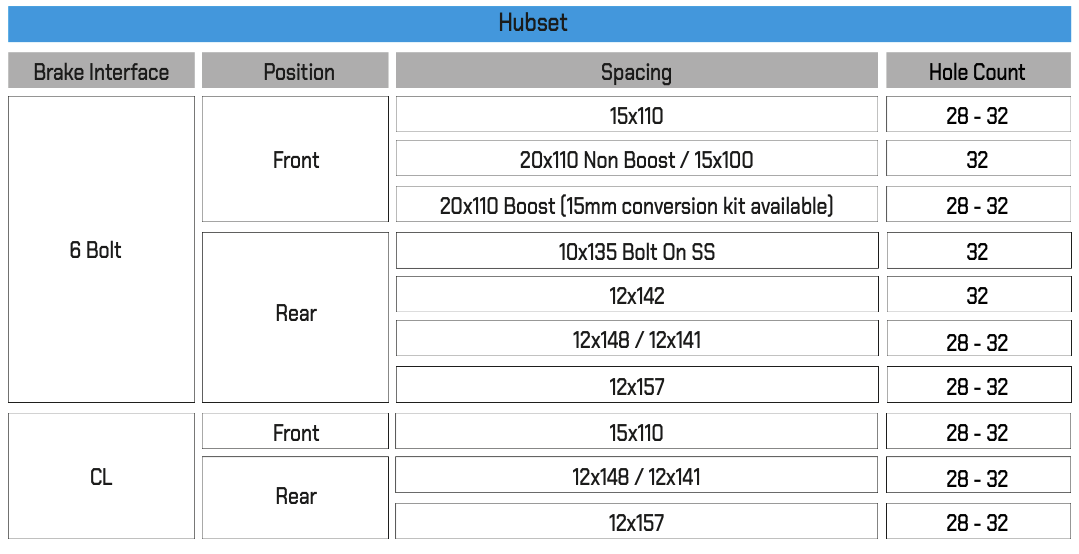

In an effort to minimize weight while increasing the spoke flange strength, the new hub has a scalloped hubshell. Hubs will be offered in Direct Thread System MTN shells with their machined aluminum spokes, or the S-Series MTN for normal steel j-bend spokes. The System hubs are offered in 6-bolt only, while S-Series is 6-bolt or Centerlock.

Thicker Axle, Revised Bearing Preload, New Bearings, New Seals

Just about everything inside the hubshell has been updated as well, starting at the axle. The new axle is 65% thicker to “dissipate stress more efficiently.” That axle now rides inside larger 6903 bearings throughout the hub along with a new labyrinth channel and full-contact radial lip seals to keep the bearings running smoother, longer.

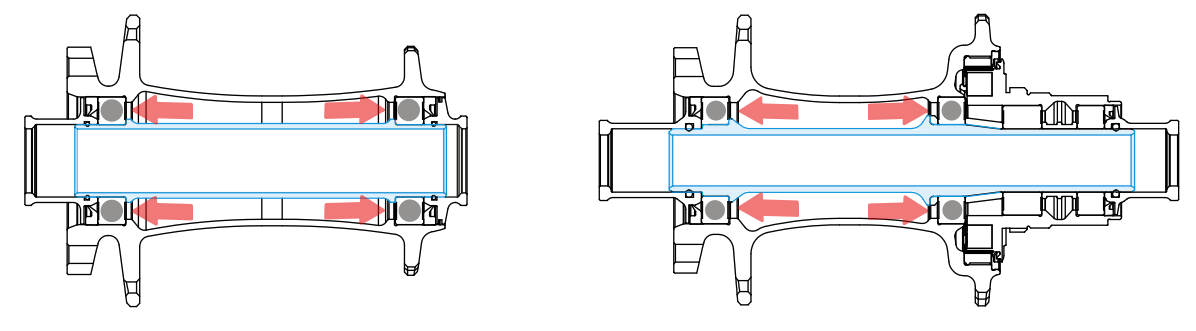

In order to prevent variations in axle tightness from affecting the bearing adjustment, a new preload design has been implemented. Industry Nine describes it as follows:

“The first bearing is pressed into the hub shell, sitting flush with both the shell and the axle. The second bearing is pressed onto the axle, sitting flush with the axle but not the shell, causing a slight amount of compression on the axle. Installing the bearings this way creates a slight compression on the axle, which pushes the bearing rings against the balls. This creates a small amount of friction. When the hub is installed in the frame or fork, the clamping force from the mounting system applies pressure to the axle. This counteracts the initial preload, relieving pressure on the bearing rings and allowing them to spin freely with minimal friction.”

This method claims to eliminate overloading of the bearings, and removes the need for additional adjustment mechanisms used on other hubs.

New Freehub

There’s a lot going on outside the freehub for the Hydra 2, but the freehub (and drivering) is new as well. The freehubs still run pawls in a phased configuration, but the new pawls have an additional tooth that mates to a drivering made from a “tougher metal”, specifically to address the needs of high-torque ebike motors. The pawl pockets have been reinforced too, with a larger 5.5mm pocket which claims to offer 26% better force dissipation to prevent the pockets from ovalizing after many years of abuse.

Oh, and the engagement is better too. Yes, somehow I9 improved on the near instantaneous 0.52º engagement, whittling it down to just 0.41º.

More importantly, I9 claims that they were also able to cut down on coasting drag by a massive 60% by optimizing the seals around the freehub. And the sound? Well, the sound hasn’t changed much. To our ears it’s maybe a bit higher pitched, but still the same I9 sound loved by those who also love loud hubs.

Current Hub Lineup

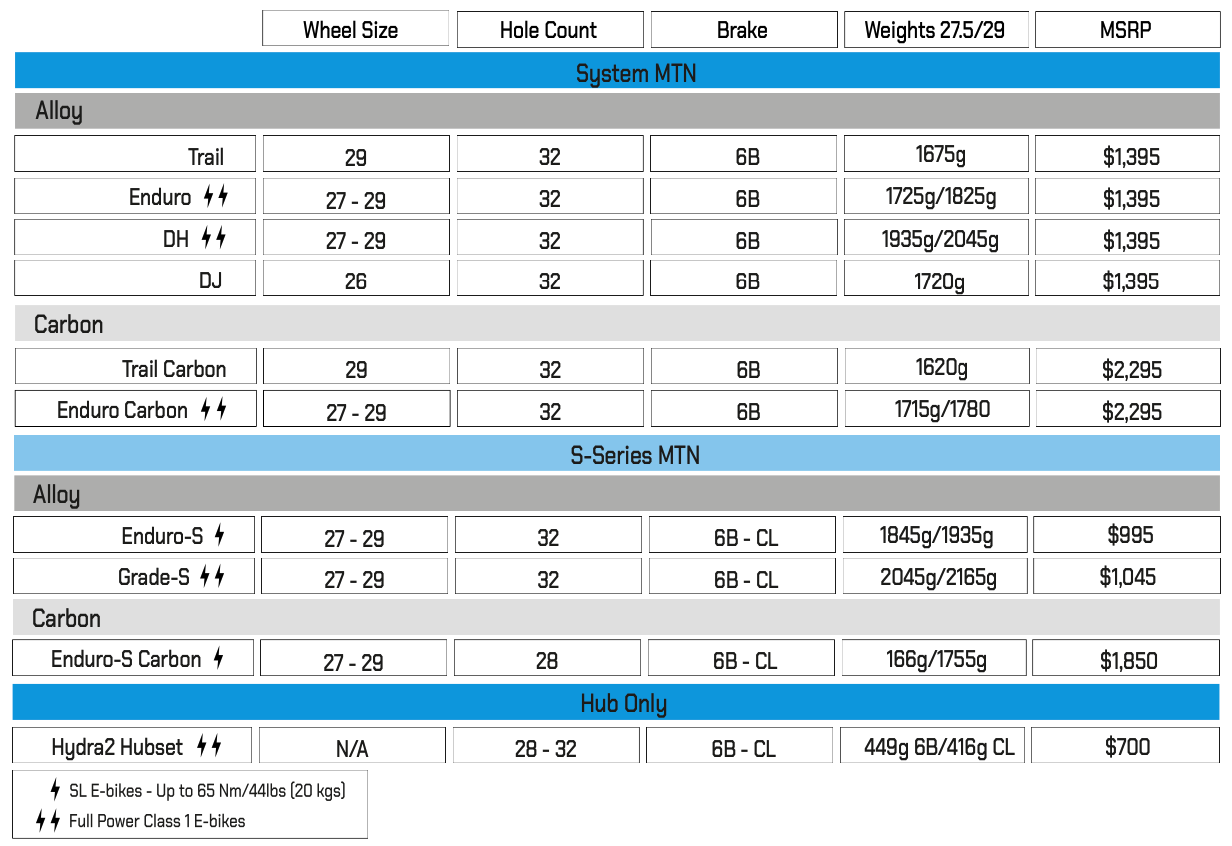

The Hydra 2 will completely replace the existing Hydra hubs, and it also shifts the line’s focus to the more aggressive end of mountain biking. The result is a product line that’s easier to understand for consumers:

- 1/1: Budget-conscious product for road, gravel, and mtb

- Solix: Road, gravel, and XC

- Hydra2: Trail, enduro, DH, e-bike

Pricing & Availability plus Hydra 2 e-bike compatibility

Hubset-only pricing will start at $700, with complete wheels starting at $995 for the alloy Enduro-S S-Series MTN wheelset. As usual, the hubs are available in a vast array of 12 anodized colors.

Note that the chart above specifies which wheels are compatible with SL e-bikes (up to 65 Nm torque, 44lbs/20kg), and full-power Class 1 e-bikes.

SL e-Bike compatible Hydra 2 wheels

- Alloy Enduro-S Series MTN

- Carbon Enduro-S S-Series MTN

SL e-Bike and Full Power Class 1 e-bike compatible Hydra 2 wheels

- Alloy Enduro System MTN

- Alloy DH System Mountain

- Carbon Enduro System MTN

- Alloy Grade-S S-Series MTN

I9 Hydra 2 Grade 300 Wheel Review

Months ago, we started talking with Industry Nine about getting a set of the new Hydra 2 wheels in for review. The timing was meant to give us plenty of time to ride and abuse the Hydra 2 hubs and have the review ready to go for the launch.

Then the hurricane hit.

It is a testament to the staff at Industry Nine that they were able to not only rally around their community and support them in a historic time of need, but also manage to design, engineer, manufacture, and launch a brand new hub platform while using their headquarters and factory to collect and distribute much-needed donations.

Needless to say, the delivery of the wheels got pushed to the very end of 2024, but I’ve still managed to get quite a few miles on the wheels since then.

With actual weights of 1,110g for the rear and 967g for the front, the combined weight with valves and tape is 2,077g.

In order to maximize my testing mileage and the amount of abuse I could inflict on them, I intended to put them on an ebike, so I9 sent the Alloy DH System MTN wheels with GR 300 v2 rims. I mounted the wheels to the only full-power Class 1 ebike I have in at the moment, the REI Co-Op DRT e3.1.

December started out wet, with closed trails so when the temperature finally dropped low enough to freeze things, it was time to ride. Surprisingly, we actually had a good amount of snow this winter, which quickly changed to ice. It’s been a terrible winter for fat biking, but it’s been great for winter ebiking as long as you have some studded tires.

Mounting up my set of Schwalbe Ice Spiker Pro studded tires proved challenging. The combination of the Grade 300 V2 rim and the Ice Spiker tires was a tight one, which forced me to use tools (and gloves), resulting in one broken Lezyne Power XL tire lever. I got them installed, and airing up the tires was instantaneous, but I’m not looking forward to wrestling them off.

I also had to make a change of rotors since the System wheels only come in 6-bolt, and the bike came with Centerlock rotors. I wanted to upsize the rotors from 180mm to 200mm anyway, so it was a good chance to change.

I don’t have a lot to say about the hubs at this point, other than they roll extremely smoothly and have been doused in mud, salt, snow, and freezing water – including a few dips up to the hubs after breaking through thin ice and really testing the waterproofing of my winter boots. I didn’t expect to have any issues yet, and I’m happy to report that I was right.

Compared to the other Industry Nine System wheels I’ve ridden, this pair is noticeably stiffer. That’s understandable considering they’re 32 spoke with the stiffest rim Industry Nine makes. I’m a lighter rider who is usually not hard on wheels, so I have no problem running 24 or 28 spokes usually. However, I9 doesn’t offer a wheel that is compatible with full-power ebikes with anything less than 32 spokes. My plan in the summer is to throw some tire liners in, and get out and smash it.

I’m happy to say that I’ve had essentially zero issues with Industry Nine wheels over the past decade or more of use. But for those who have broken hubs, the Hydra 2 seems to have improved in every way to deliver a more durable hub. Hubs that will keep your bike rolling with less maintenance.