Will SRAM making their next-gen mountain bike derailleur modular alleviate all of those direct-mount fears? We’ve been sneaking peeks left & right at the next evolution of SRAM’s top-tier direct mount XX1 Eagle AXS derailleur, ever since Nino Schurter rode it to a record 10th XC MTB World Championship last summer. But we’ve actually been discussing the SRAM direct mount solution for more than four years already. Will a modular construction solution address the biggest longevity concern that both our readers and our own editors have voiced since then, while helping save the planet a bit at the same time?

SRAM Eagle modular direct mount derailleur

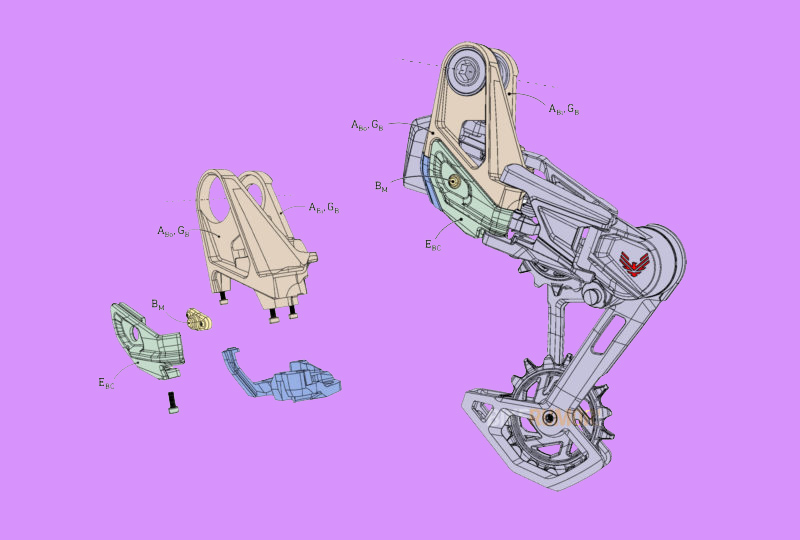

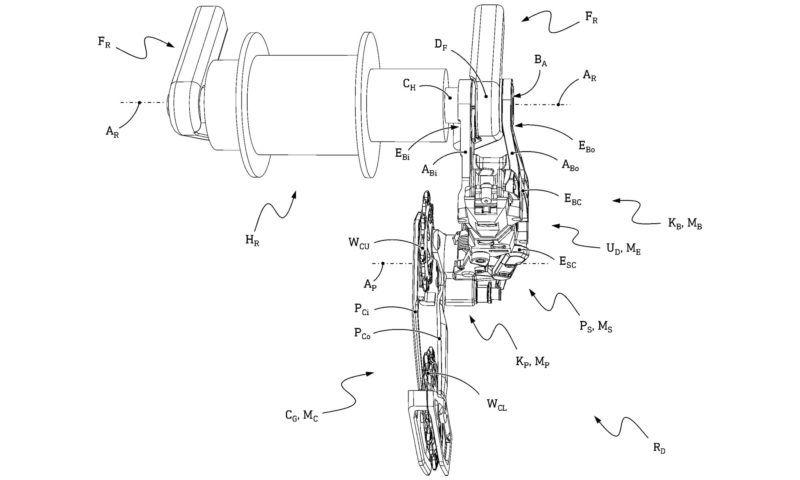

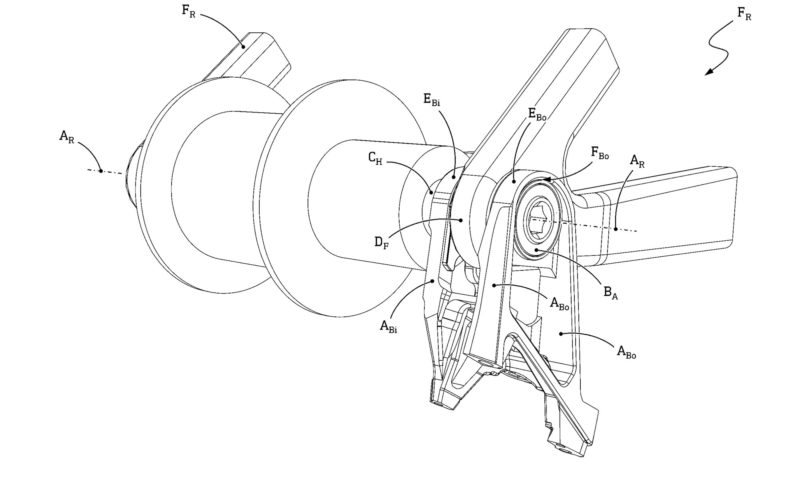

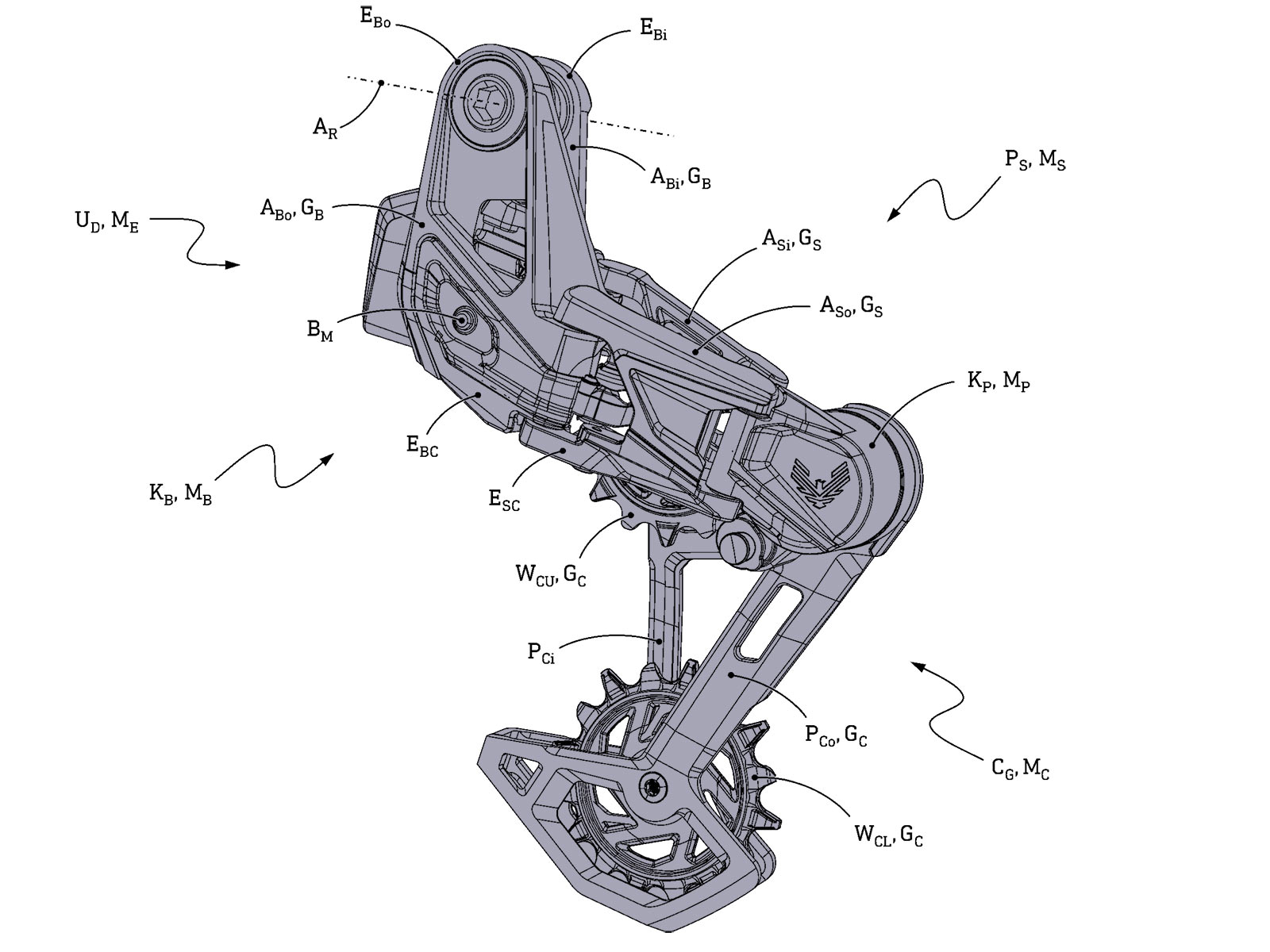

Based on Nino’s prototype, bikemaker leaks, World Cup podium photos, and not-so-secret event photos… the overall details of SRAM’s upcoming Eagle mountain bike derailleur overhaul are pretty clear. The standout feature of course, has been the absence of a derailleur hanger interface, instead mounting directly to the bike frame at the rear axle, thanks to the UDH interface that has quickly become an actual universal standard across many bikemakers.

But while promises of improved shifting sound nice, many cyclists (including both our readers AND our editors) have been worried about the rough-and-tumble life of their derailleur. The low-cost replaceable & sacrificial derailleur hanger has protected your expensive rear derailleur for decades. Remember a SRAM UDH costs $16 / 18€ and an XX1 AXS derailleur sells $753 /831€. So when you crash or simply hit a trailside rock, that could be an incredibly expensive problem. I know many have the philosophy or never riding a derailleur that you can’t afford to replace, when it will invariably be damaged.

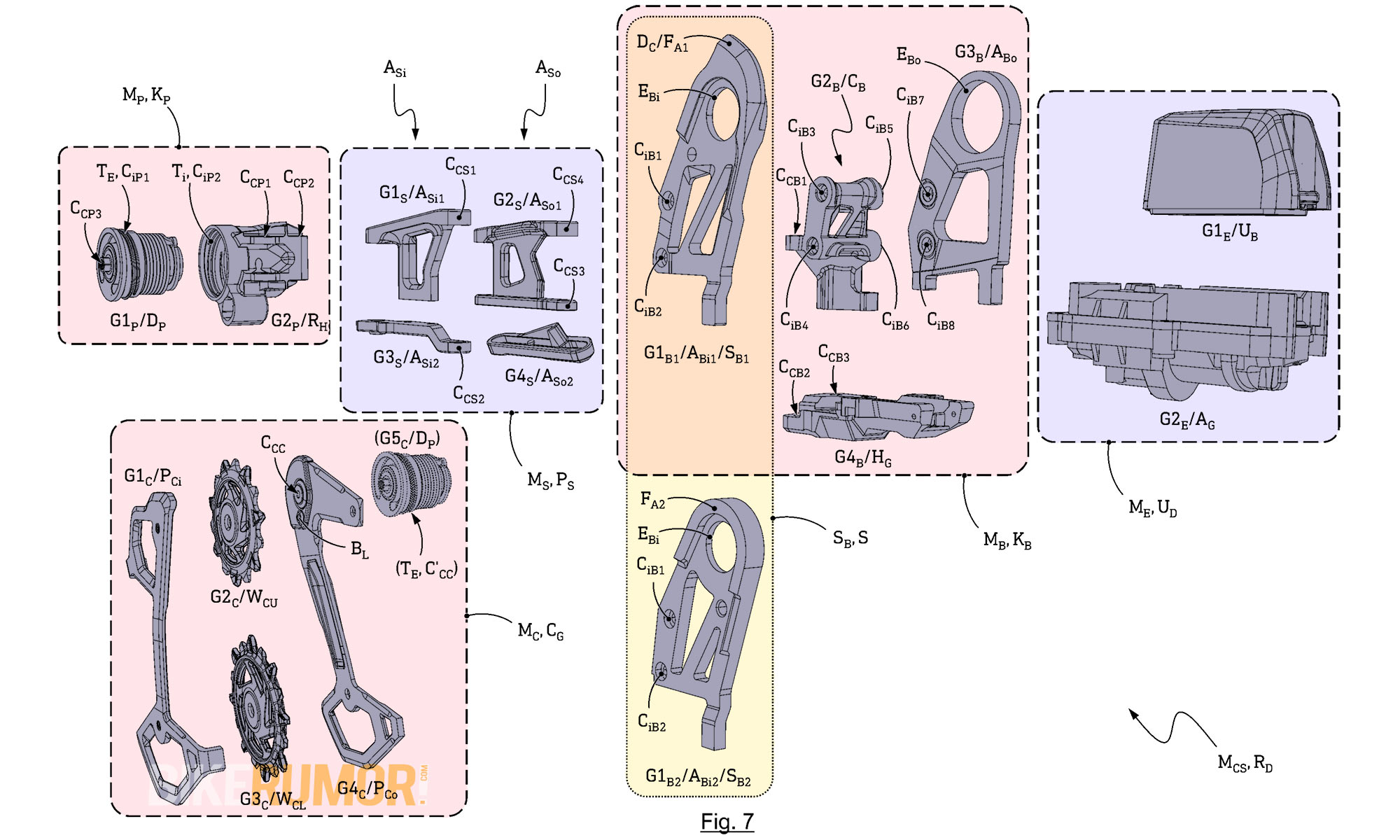

SRAM’s latest patent published December 29, 2022 describes a modular derailleur construction that is comprised of several different modules that should be able to each be replaced separately: “base element module”, “swivel formation module”, “shifting element module”, and “chain guiding module”. It’s not revolutionary at all that a derailleur could be rebuildable, but SRAM generally has limited real serviceability in all but their top tier, and this statement from the patent is especially interesting:

“Detachable connection interfaces of the family members to adjacent sub-assemblies of the module within the sub-assembly are configured uniformly across family members for the respective sub-assembly in such a way that a family member of the sub-assembly family module is exchangeable for another family member of the same sub-assembly family that, is for example, of different material, of different design, of different functionality, of has different surface properties, while retaining the remaining sub-assemblies of the module.”

That sounds a lot to me like if you break some part of your XX1 derailleur, a universal or lower-cost GX part may get you back on the trail.

Replaceable Modular Elements

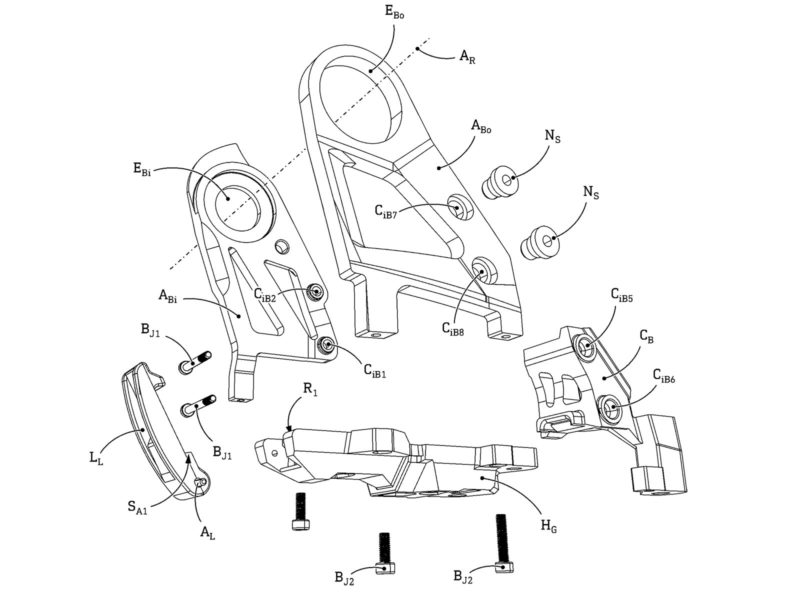

SRAM’s published patent shows a number of broken-down component assemblies, that could be individually replaced. You’ve got replaceable cages, what looks like a replaceable clutch, a replaceable middle shifting assembly in the case of AXS derailleurs, and in the middle a replaceable hanger assembly.

In fact, SRAM’s direct mount derailleur may be getting rid of the conventional derailleur hanger, but it looks like a replaceable hanger of sorts is here to stay. Simply speaking it looks like two hanger elements that sandwich the frame’s dropout (ABi & ABo), and a lower plate (HG) that holds them together and serves as the basis to hang the actual derailleur below.

Interestingly, that inboard ABi side of the hanger has more than one variant shown in Fig. 7 suggesting compatibility beyond the UDH standard interface. Perhaps that will help bring backwards compatibility to non-UDH bikes?

What do we know, now?

The published US & DE patents are pretty long & detailed for simply talking about a rebuildable modular rear derailleur. But SRAM also goes deep into why they’ve gone down this direct-mount route. Essentially they break it down into improving shift performance across modern wide-range 12-speed drivetrains (which are more sensitive to derailleur hanger misalignment than ever) and to an environmental benefit, as well.

Cynics might call it greenwashing, but it really is silly how many different derailleur hangers are out there these days. UDH has already done a lot to improve that issue. But SRAM takes it further suggesting this new modular solution is an even more responsible use of consumed resources. No more “throwaway mentality” and a move toward “increasing demands on the service life and reparability of technical products“. Bringing back the idea that you can simply replace the part of a derailleur that is damaged sounds like a great idea to me (us).

Lastly, while we don’t know exactly when this will be launched, we do know that there is a lot of detail out there at this point on this derailleur. And we really expect this complete new drivetrain to come very soon. We’ve got our eyes peeled for when SRAM make official their release schedule for this next-gen Eagle mountain bike drivetrain

Thanks to an anonymous reader for the tip!