With an update promising better performance and stronger wheels, ENVE’s carbon road brake hubs arrived laced to their SES 5.6 aero carbon rims ready for review. First introduced in 2015, the hubs use a made-in-the-USA carbon hub shell that was slightly updated to reshape the flanges and make them stronger. The insides received more intensive updates to make them roll and engage more quickly, and improve long term durability. Here’s how all those changes faired on the rolling hills outside Bikerumor HQ…

ENVE carbon hubs actual weights

In the box were premium machined valve stems made for them by Silca, rim tape, and skewers. The hubs are only available with standard quick release end caps. Brake pads are also included, which are designed specifically for their textured braking surface (shown further down).

Claimed weights for the hubs are 70g (F) and 185g (R), which when built into complete wheels with mid-height aero rims come in at 673g (F) and 828g (R) for a total wheelset weight (without tape or valves) of 1,501g…very light for a deep aero wheelset.

Add tape (usually about 20g) and valve stems and you’re at about 1,550g rolling weight. The included skewers are respectably light at 89g, which is especially good considering the cammed lever mechanism that helps keep them closed once installed.

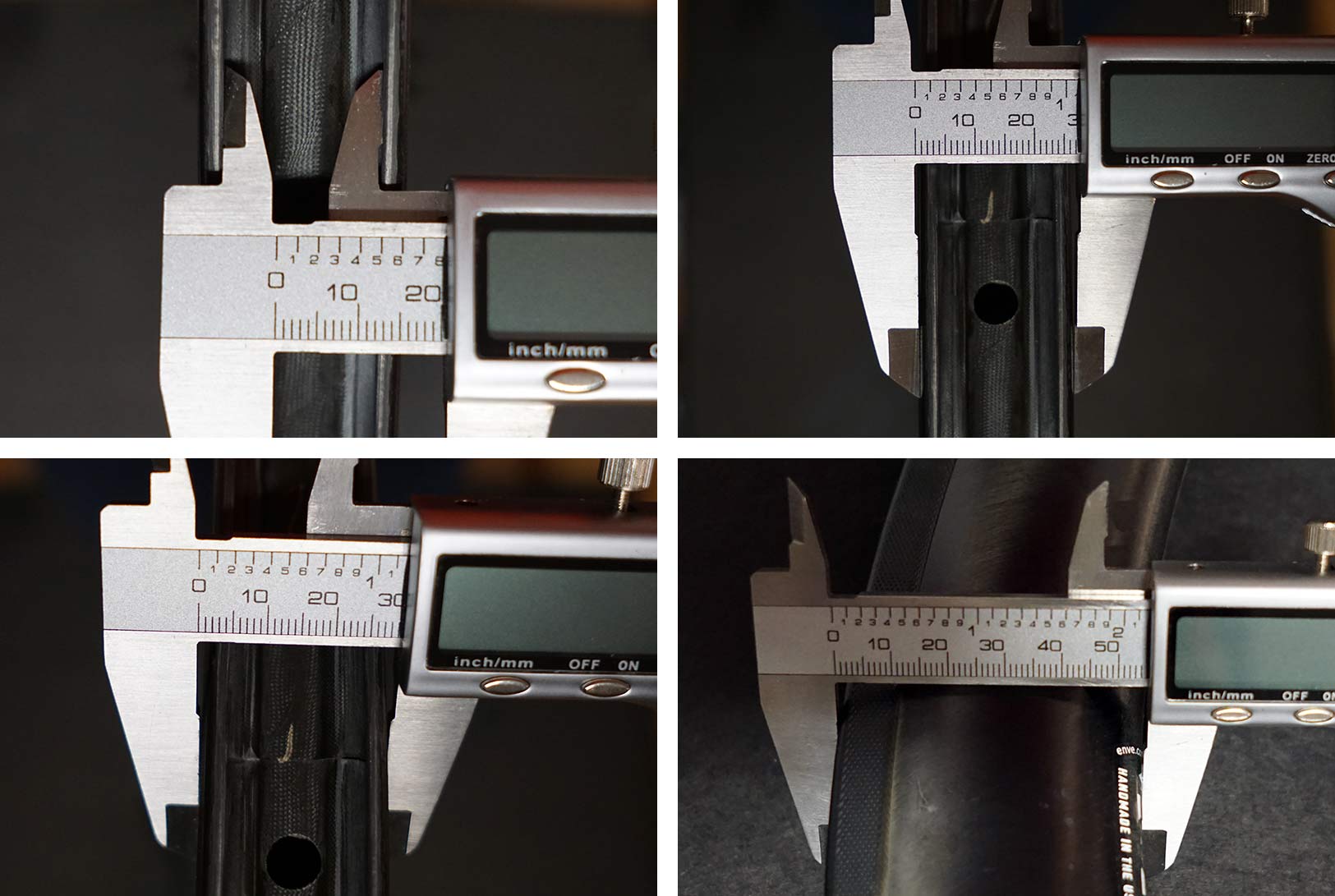

The focus here is the hubs, but rims are a necessary part, so here’s their measurements:

- Internal width: just over 20mm

- External width (brake track): 27.5mm

- External width (widest point): 29mm

- Depth (rear rim): 56mm (front is shallower, not measured, claimed at 48mm)

What’s inside ENVE’s carbon hubs?

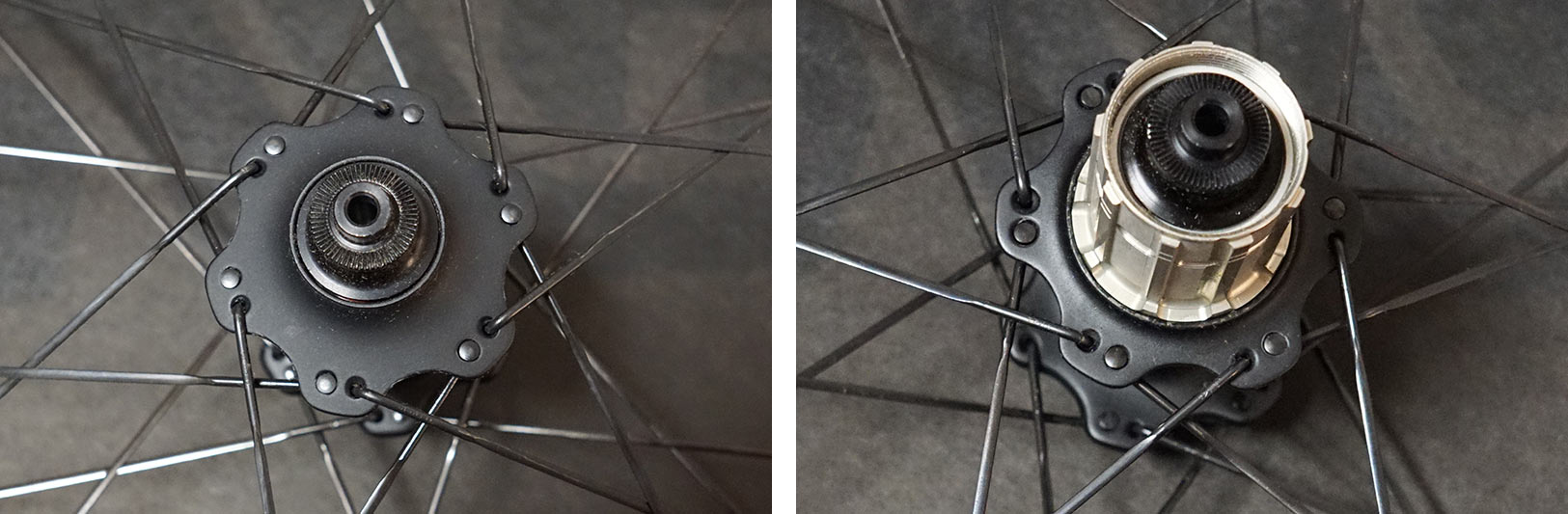

One of the big updates to the insides was the switch to Mavic’s ID360 ratchet ring. This is a 40-tooth set of rings that use a flat coil spring on the outboard side to maintain contact. It’s not overly loud (not even what I would call “loud”), but offers decently quick engagement for a road bike.

The other aspect of the Mavic system is a wave washer on the non-drive side to maintain even pressure on the bearings. This eliminates the need for any bearing preload system, which adds weight and complexity (read: opportunity for user error).

The rims use their molded spoke holes and flat-top molded valve hole on the exterior…but internal spoke nipple access holes are made the old fashioned way.

ENVE’s road tubeless rims still use a bead hook for higher pressure applications, and have a small bead shelf bump to help keep the tire in place.

How do they ride?

I mounted the wheels to my sole remaining rim brake road bike, a Culprit Arrow One, and hit the road. After a couple test laps, Watts and I headed 70 miles east on rolling terrain to meet our families at Haw River Farmhouse Ales in Saxapahaw, NC, for a big lunch and a few well-earned bevvies.

One of the goals in the updated hub design was to make the rear wheels laterally stiffer to reduce brake rub. ENVE’s textured rim braking surface makes noise when you brake -not a bad noise, I think it’s cool, kinda like a turbo spooling down, but it’s a noise nonetheless- so reducing flex means quieter sprints. Without having ridden the first generation, I can’t say if they’ve improved it, but there is still a bit of brake rub under standing efforts ranging from slow, exaggerated grunts to full-on city limit sprints. It’s not too bad, and adjusting my calipers outward just a little eliminated most of it. And I didn’t hear any rubbing during cornering.

Having gone almost exclusively to disc brakes on all of my bikes, any rubbing is noticeable. But if I try really hard to remember what it was like back in the old days, in terms of lateral brake rub, these seem on par other high end wheels.

Which means it really comes down to the rolling performance to justify the hubs’ $450 price jump over their alloy hubs (retail for this clincher wheelset is $3,000, up from $2,550 built with ENVE alloy hubs…but same as $3,000 built with Chris King R45 hubs). Well, that, and a 98g savings over the alloy ENVE hubs.

And they do roll smooth. Very smooth. Put the bike in the stand and spin them and they just keep spinning. Roll along a country road or coast down the hill and they feel effortless. Sure, they’re broken in now, but not every wheel I’ve ridden feels so frictionless.

Up front, I didn’t notice any brake rub during the standing sprints and grinds, even when intentionally leaning the bike waaaay over.

It’s hard to say much else…I haven’t ridden them long enough to see how they wear (metal on carbon, afterall), but ENVE offers a lifetime warranty on everything they make now, so that’s not something I’d worry about, either.

Conclusion: If you’re in the market for a high-end rim brake wheelset and are already considering ENVE’s wheels, these new hubs offer an exceptionally lightweight way to upgrade any rim depth you want to ride. With a price that’s equal to other upgraded hub options but still lighter, and “system engineered” specifically for their rims, it’s easy to recommend these.

Learn more at ENVE.com.