It’s finally time. Time for an all-new XTR drivetrain from Shimano. We’ve been waiting for years. Not just for the next generation of XTR, but for a generation that had to reintroduce Di2 shifting to the world of mountain biking. While Shimano has recently offered electronic shifting for eMTBs, regular mountain bikes have been left out for years– while SRAM has been pumping out AXS wireless shifting groups, including the newer Transmissions.

It’s fair to point out that the current Shimano mechanical mountain bike drivetrains are still as good as ever. They’re dead reliable, shift incredibly fast, and won’t ever leave you stranded before a ride after forgetting your battery on the charger.

But modern mountain bikes have changed, and riders’ expectations have changed with them. Over the course of the development of the new XTR Di2 group, Shimano placed a greater emphasis on listening to the market, particularly the MTB market in North America. More riders than ever want wireless electronic shifting, so Shimano is finally delivering.

It might look like Shimano is way off the back and late to the party. In reality, Shimano was forced to take it slowly. Still, the result is a group that addresses most of the shortcomings of wireless, electronic shifting in a way that is not only more durable but also more affordable than you would expect.

Why did it take so long?

I asked Shimano’s MTB Product Manager, Nick Murdick, why it took so long to develop and introduce XTR Di2.

His blunt response? Patents.

There are, not surprisingly, many, many patents that cover how one may attach a battery to a rear derailleur. To avoid patent infringement, Murdick says Shimano had to take their time to research all of the potential conflicts and then develop a system that not only steered clear of patent infringement, but was ultimately better. The interesting point here is that if there weren’t so many patents to avoid, it would have been tempting for Shimano to take the easy way out. Just slap a battery on the back of the derailleur and call it done.

Instead, the battery location became part of the lengthy XTR Di2 development of a system that is ‘built to survive’. Not only is the battery protected inside the parallelogram, but it’s part of a derailleur design that is meant to make it impervious to rock strikes.

How does a rock hit a derailleur?

How does a derailleur break? That becomes an even more important question when you’re dealing with expensive, electronic rear derailleurs. It doesn’t matter how fast your fancy derailleur shifts if it gets destroyed the first time it meets a rock. Offering rebuild parts is nice, but needing them usually means the end of your ride – or race. Instead, Shimano aimed to build a derailleur that could take the hits and keep on shifting.

During their initial research and development, Murdick spent nearly a whole year on the race circuit with various teams like the Yeti Race Team with Mick Hannah and Richie Rude. Spending more time with them during testing rather than just on race day led to what they called the “hall of broken parts.” As pro EWS racers scout lines from new courses, first hits are often a make it or break it scenario. When something broke, it resulted in an opportunity to study the failure mode on essentially brand-new parts. After the races, every broken part was sent back to Japan for further testing. The data collected led directly to the design of the new group.

It turns out that one of the most common ways to kill a derailleur is a good ol’ rock strike to the front of it. Shimano found that the leading edge was the most likely part of the derailleur to get hit, and the most likely part of the derailleur to cause a failure if struck. The addition of the clutch to mountain bike derailleurs was a huge improvement in chain stability and noise reduction, but it also placed a big, wide knuckle on the front of the derailleur, which serves as a perfect target for rocks.

No more clutch

Clutches also only provide resistance for the initial force, but once they break free, the derailleur can move freely. Murdick likened this to moving a refrigerator – it takes a lot of force to get it moving, but once it starts moving, it’s pretty easy to keep it moving. Clutches also require regular maintenance, which is something that isn’t often done or completely understood.

The answer? You’ll no longer find a clutch on the XTR derailleur.

Instead, you’ll find a “slim stabilizer”. This is a fancy name for a dual spring design that allows for a much slimmer design for the front of the derailleur. The stabilizer doesn’t have an on/off switch, never needs maintenance, and will have almost zero degradation of performance over time (Shimano’s claims). It also offers 72% higher chain tension with better chain wrap and engagement.

Starting with the Slim Stabilizer, the derailleur design continues into what Shimano calls their low profile skid plate design, or Shadow ES. The derailleur body is essentially a wedge, and if that wedge is struck, the shape encourages the object to slide out to the side and off the back.

Automatic Impact Recovery

That may work for gentle strikes, but what about the really big ones where the rock doesn’t move? That’s where Shimano’s new Automatic Impact Recovery comes in. Shimano Di2 derailleurs have offered Crash Recovery previously, but this is the first time that the derailleur will automatically recover on its own. When hit, the derailleur has a sensor and a torque limiter that allows the derailleur to move, and it remembers and returns to the original position after impact. Previously, you would have to stop and activate Crash Recovery mode or shift around until you lined up the servo motor with the right gear.

Automatic Impact Recovery is so seamless, you might not even notice it working – though you’ll probably see some scrapes on the derailleur. Shimano has thought about that too. Instead of using aluminum on parts of the derailleur that are likely to be hit, they use resin materials for the P-body, battery door, and bottom parallelogram cover. These resin parts won’t show damage the way raw aluminum would, and they’re all replaceable if they get too beat up.

Battery protection

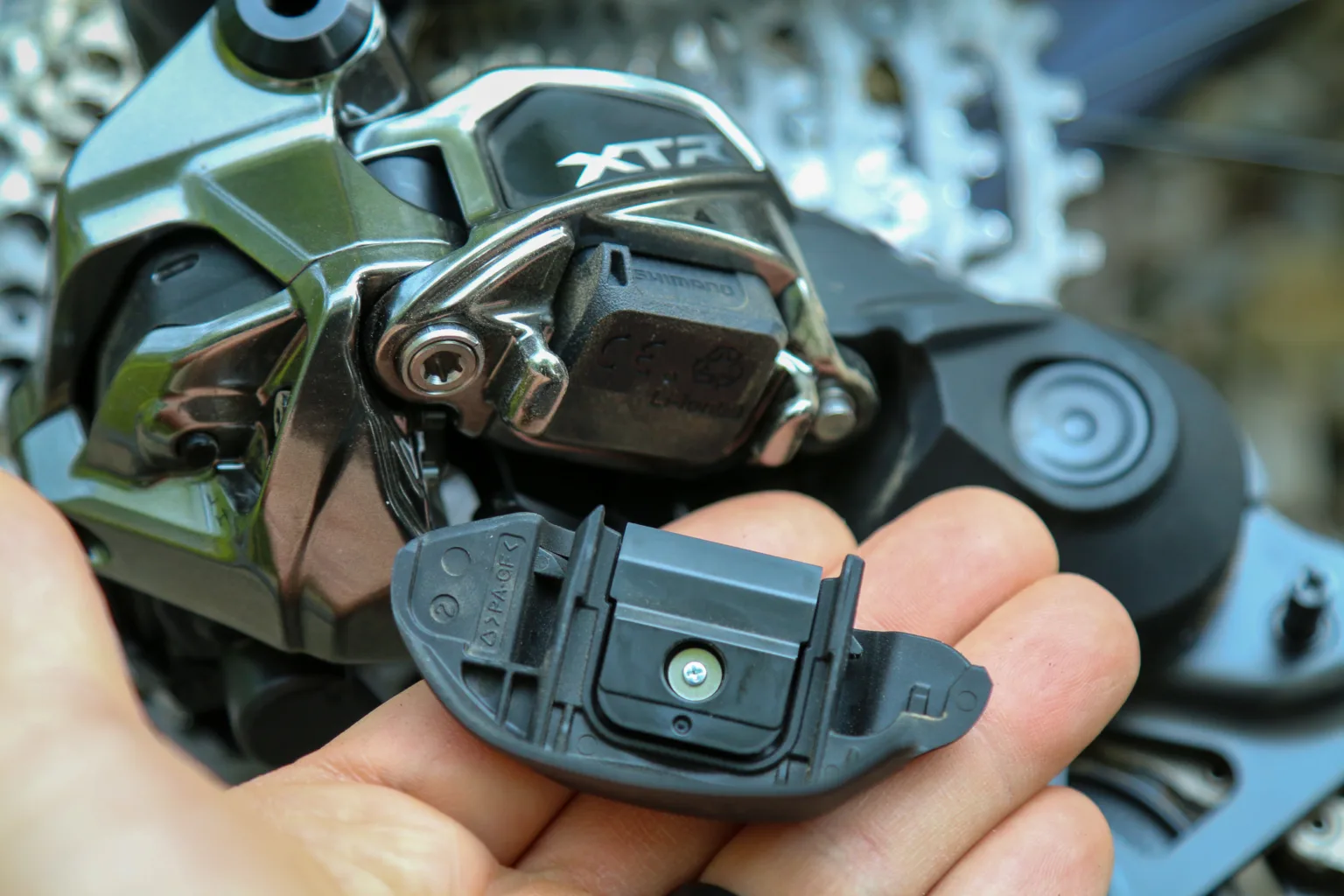

That Low Profile Skid Plate Design also serves to protect the battery. With its location inside the parallelogram, any impact should glance right over the battery door without issue. If you do manage to hit the battery door hard enough to damage it, the cover also serves as breakaway protection. That cover will rip off, but the metal locking wedge underneath will stay in place, which will keep the battery in place and protected.

Shimano also positioned the battery so that the terminals are facing up, inside the cavity. There is a small diameter rubber seal around those terminals, providing excellent protection from water and dirt. There’s also no way to install the battery in the wrong direction to keep things simple.

The 305mAh battery is said to last around 210 miles on average, and includes power-saving functions to prevent it from draining when not in use. You can put your bike on a bike rack and do a long road trip without the battery draining, for instance – as long as you don’t hit the shifter before loading it. Manual input from the shifter is required to wake up the derailleur, so as long as you don’t shift it, you’re good.

Batteries and charging

Each group and complete bike will include a USB-C charger with a cable (Shimano says this is important, since not all USB-C cables are created equal) that will charge the derailleur battery in 45-60 minutes. Battery life is indicated through an LED on the derailleur, which stays green until you hit 25% battery life, and it turns red. Note that this is a proprietary battery and does not currently work with anything else. Shimano will sell spare batteries so you can have an extra charged and ready to go – which might be a good idea since when the battery dies, the derailleur will stay where it is.

The shifter has the only other batteries for the system and uses double-stacked 1632 coin cell batteries, which are said to be good for more than a year.

A traditional derailleur hanger?

The design story continues to the derailleur mount, which uses a traditional derailleur hanger – not a direct mount. You may expect that this is Shimano’s way of avoiding more patents, but they claim that is not the case. With modern derailleur hangers, Shimano points out that many derailleurs will still break before the hanger does. So if they can build a robust derailleur that won’t break, then the derailleur hanger can do what it’s designed to do – bend or break in an impact, saving the frame or derailleur and allowing for easy replacement trailside.

Having a derailleur that you can stand on is great, until other parts of that derailleur break, rendering it useless. Parts that aren’t typically able to be repaired trailside. Using a traditional hanger also makes for easier setup and maintenance in many situations. Note that while the new XTR Di2 derailleur does not use a direct mount, it is still compatible with every UDH frame using the UDH derailleur hanger.

Shimano does mention that they recommend premium aluminum derailleur hanger replacements (like the Wolf Tooth Components UDH) rather than the plastic co-molded SRAM derailleur hanger often included with new bikes. While that plastic is supposed to help the UDH derailleur hanger rotate backwards in an impact to help save the derailleur, Shimano claims that, in testing, that rarely happened, and aluminum hangers offered better performance. The derailleur is also free to rotate around the B-axle due to the inherent design, which is another mechanism used for its protection.

Robust cage and pulleys

Wondering why the derailleur cage looks a bit different? A more solid cage shield and solid pulleys are used to prevent any sticks or other objects from getting into the derailleur cage and ripping it off.

Still 12-speed (And backward compatible!)

You know that whole listening-to-the-market thing that Murdick mentioned earlier? Not surprisingly, there isn’t a lot of clamoring for one more gear that requires new chains and cassettes. By keeping their existing 12-speed Hyperglide+ shifting, Shimano was able to create a system that shifts super quickly and is compatible with the 12-speed Hyperglide+ chains, chainrings, and cassettes you might already own.

That means if you currently have a Shimano 12-speed MTB mechanical drivetrain, you can upgrade to Di2 with only a shifter, rear derailleur, and a new quick link (which Shimano offers as a convenient upgrade kit). That’s huge for making the group more accessible.

Compact GS drivetrain design for even better protection

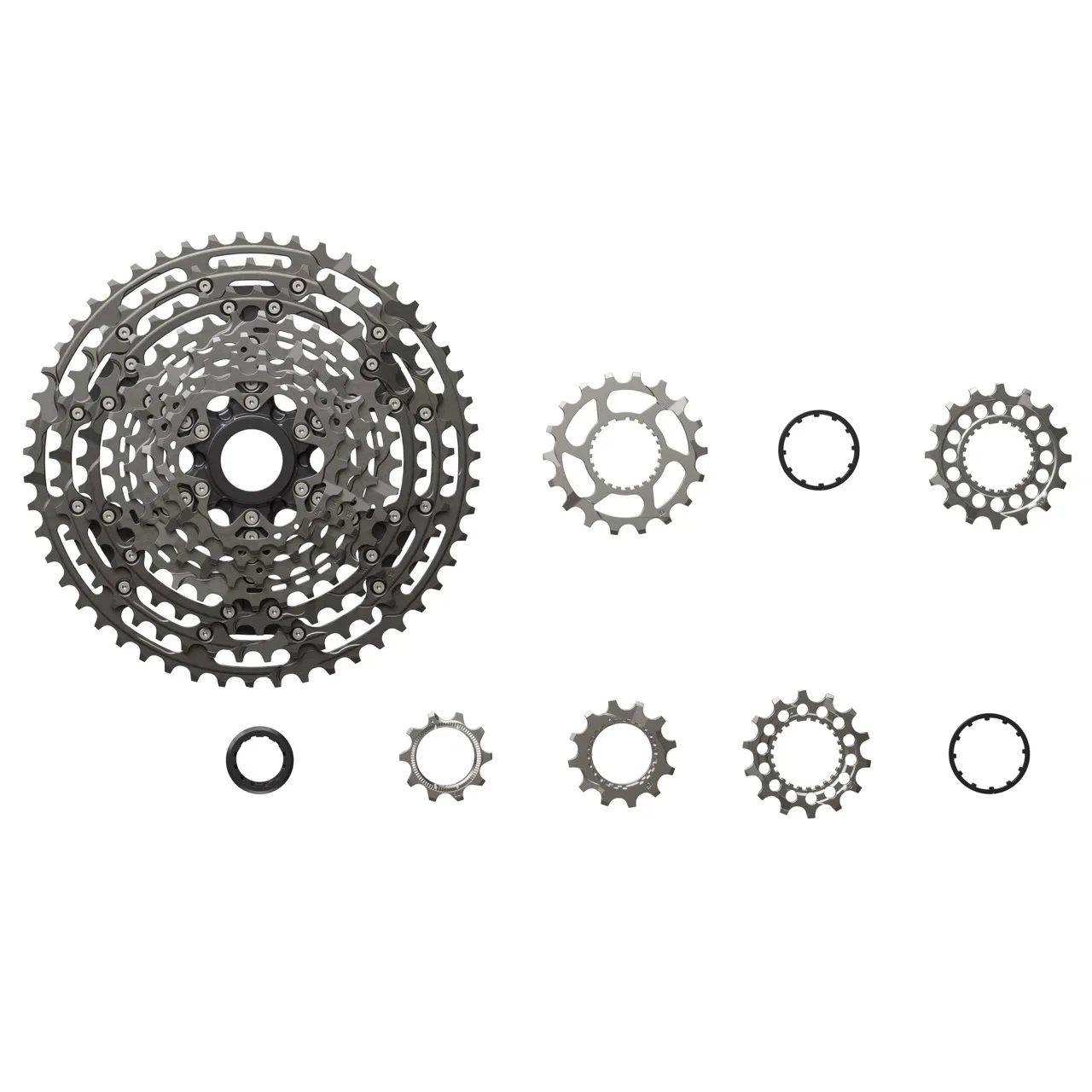

If you’ve been paying attention, a compact drivetrain is nothing new for Shimano. In fact, almost all of their sponsored EWS racers are currently on short-cage derailleurs with compact cassettes now. The difference is that now they will have a 12-speed version of that compact drive thanks to a new 9t cog. Shimano managed to squeeze in the 9t cog with a new lockring that requires a specific tool. To make it work with a 9t cog, the cassette lockring has the splines on the outside instead of the inside.

That’s a small price to pay for a GS drivetrain that offers almost the exact same range as the standard system (500% vs 510%) but with the most trail clearance and the lightest weight. Specifically, you’ll gain 23mm of clearance at the derailleur cage, 8mm at the front chainring (since you will typically size down 4t up front), and you’ll drop 70g. You’ll also land a quieter drivetrain with a shorter chain with less bounce.

If the compact drive is so good, why won’t everyone use it? For starters, the 9-45t cassette is not approved for full power ebike usage. It also will depend on the frame, some chainstay designs will run into issues with clearance for the chain when it’s in the 9t cog. However, Shimano does expect to move from 5% to 25-30% OEM spec for the compact drive, and it seems like it will be a popular choice for bikes with smaller wheels.

There are new cassettes (but you don’t need them*)

First things first. If you have a current Shimano 12-speed Hyperglide+ cassette and chain, you don’t need a new cassette or chain to install the new XTR Di2 group (just a chain quick link since they’re one-time use).

However, there are new XTR cassettes with some slight changes. The most obvious is that the three largest cogs are no longer black. The XTR cassettes feature a superior anodizing process for the cogs, but it’s not naturally black, so the previous XTR cassettes had painted cogs on top of that anodizing just for looks. Paint will wear faster than anodizing, so Shimano got rid of the black coating and now just has the natural anodized finish.

Additionally, the largest titanium cog now has a wider base to improve its stiffness and strength. The cassette rivet structure has also been updated to prevent noise and loosening.

*You will need the new cassette if you’re going to use the new compact GS drivetrain with the 9-45t cassette. To make that tiny 9t cog work with the cassette lockring, Shimano changed the lockring on the GS cassette to have external tool splines, rather than internal. That requires a new tool, which Shimano will offer in the TL-LR021.

Additionally, we know that at least Abbey Bike Tools will have a compatible lockring tool, which they plan to build into a Crombie tool with a standard HG spline tool on one side, and the 9t spline tool on the other.

Still the same 12-speed chains

Chains have not changed for this group, so any Shimano Hyperglide+ 12-speed chain will work. As noted, if you plan to reuse your current chain, Shimano states you will need a new quick link since they are one-time use only. If you purchase a drivetrain upgrade kit, a new link will be included.

New crankset is the lightest ever Hollow Forged, with new chainring (but also not required)

Not too long ago, Shimano thought that they had pushed their Hollow Forged crank arms as far as they could. Hollow Forged means the arms are created in one solid piece of aluminum and, through a series of proprietary forging steps, the hollow arms are created, making them super strong.

To seek out lighter weight, at this point, Shimano went to their Hollow Bonded design with two separate halves bonded together. However, Shimano made new gains in their Hollow Forged technology, leading to their lightest one-piece arms ever. This design is supposedly within 10g of their previous XC crank but with an Enduro-specific BB spindle for big hit survivability.

The crankset will be offered in XC and Enduro tailored q-factors with 168mm or 176mm, noting that some race teams are starting to prefer the wider q-factor since it places the rider’s feet more under their hips.

All of the cranks have a 55mm chainline and a 24mm steel spindle that uses the same Shimano bottom bracket as previous. XC cranks will be available in 165, 170, and 175mm lengths, while the Enduro cranks will gain an additional 160mm length.

There is also a new direct mount chainring solely for durability. During all of that testing mentioned above, Shimano noted that chainrings almost always broke in the same location – the bottom of the chainring with the crank arms horizontal.

To address that, the new rings have more material in those two quadrants, and almost nothing in the other two. It’s said to be much more durable without adding extra weight. Keep in mind, though, that the new chainrings are not required for the group. If you have an existing Hyperglide+ compatible chainring, that will work just fine.

55mm chainline with 0mm offset rings

It’s important to note that while the new chainrings use the same direct-mount interface as the previous Shimano rings, there is a difference in chainline. The previous Shimano direct mount rings were all 3mm offset, and the cranks used spacers between the crank and the frame, along with different spindles to get to a 55mm chain line. The new M9200 cranks use a dedicated 55mm chain line without any spacers between the crank and the frame, which means the new rings are 0mm offset.

The new shifter has the best ergonomics

To quote Nick Murdick, “there is a tremendous temptation to try and make a shifter ‘better’ when you’re not constrained by typical mechanical shifter needs.”

What does that mean? It means that electronic groups only require a button to actuate the derailleur, so it’s very tempting to design some kind of two-button setup and get away from the traditional shifter design.

But in testing, Murdick states that the best you could hope for is a 50% success rate with button-style shifters, meaning half of the people would like it, but half of the people would hate it. At the end of Shimano’s testing, most riders still wanted to try it with a standard shifter style – which was the only way they got that approval rating over 50%.

Highly adjustable shift paddles

That’s not at all surprising when you get your hands on the new shifter. It is amazingly adjustable with all of the traditional adjustments you’ve come to expect from i-Spec EV, but with the addition of individual shifter paddles that can be rotated and adjusted in angle. The same bolt on each paddle allows for both adjustments, making it so you can put the shifter paddle in exactly the spot you want – making it even better than a traditional Shimano shifter.

In addition to the two shift paddle buttons, there is a third button located on top of the shifter. This is initially set up to allow for on-the-fly, one-handed adjustment of the derailleur trim. This was a specific request from a racer so that if their derailleur took a hit and wasn’t shifting perfectly, they could trim the derailleur to their desired gear without having to stop.

That button can also be programmed for other functions and is designed to pair with a Garmin or other 3rd party electronics to function in the same way as the extra button on Shimano Di2 road shifters.

1-shift, 2-shift, or Multi-Shift

When it comes to actually shifting, you technically have three options. You can hit either paddle once, and it will shift one gear. You can also push through that first click to the second click, and it will shift two gears. That second click is physically harder than the first to help prevent accidental over-shifting if you’re trying to just shift one gear. The double click allows you to drop or add gears in a hurry. Finally, you can push and hold either shifter, and it will work its way through the full cassette.

Underneath the shifter, you’ll also find a bolt that allows you to limit the shifter to one click. The standard configuration allows for either one or two clicks, and it’s easy to use both while riding. However, if you wanted to prevent the shifter from the double click, you can limit it out on the shifter.

According to Shimano, their wireless shifting is actually faster than a wired electronic shift, thanks to the wireless protocol, which is the same as their dropbar levers. The system also has the ability to tune shift speed and number in the E-Tube Project app.

E-bikes get different options

Shimano calls the new XTR group E-Race ready, and with that comes a few drivetrain options. You can run the standard XTR Di2 drivetrain where the derailleur has its own battery, and just run it in ‘E-bike Mode.’

When asked about e-bikes and the double shift feature on the regular drivetrain, Murdick responded, “We fully endorse double shifting on e-bikes. It’s still possible to have really fast shifting on an e-bike. Our derailleurs have an e-bike mode, which encourages the chain to use the shift gate when climbing up to the three largest cogs. It will do half the shift, then finish it after a short delay. If you do a double click at the shifter, the derailleur will do 1.5 shifts immediately, then finish the last half shift.

E-bike mode does not have any effect on shifting to smaller cogs or the speed of multi-shifting. Wireless derailleurs have an e-bike mode that can be turned on or off in the e-tube app. Wired derailleurs are always in e-bike mode, naturally. Note that all derailleurs ship in e-bike mode, so it needs to be turned off when installing on a regular bike. The lone exception is the GS derailleur. Since the 9-45 cassette is not recommended for e-bike usage, there is no e-bike mode.”

The wired drivetrain Murdick is referring to is the other option for e-bikes. Instead of using an onboard battery, the rear derailleur is wired to the e-bike battery and offers Shimano Auto shift and Free Shift tech. While the normal XTR drivetrains are all 12-speed, there are both a 12 and 11 speed option for the e-MTB rear derailleur. The 12-speed e-MTB derailleur is the Hyperglide+ model with the fastest shifting, while the 11-speed model is Linkglide for increased durability.

All new brakes with new brake fluid

Still with us? Good, because there’s quite a bit more, including all new brakes that also use a new brake fluid – though it’s still mineral oil. According to Shimano, the new ergo brake lever design was inspired by enduro racer and UBI instructor, Nathan Riddle. Nathan is no stranger to product development (just look at the WTB Riddler tire), and he wanted the brake lever pivot closer to the bar so the lever arc would be more in-line with how your finger actually moves.

Shimano took that concept and moved the brake lever pivot 5mm closer to the bar, and also angled the brake levers up by 5º. In order to make the master cylinder design work, they flipped the brake assembly around and made a pull-master cylinder, which is what their dropbar levers use. According to Murdick, he rode the prototype once and was convinced.

The new lever design also allows for a new clean cockpit hose routing with hose routing that is closer to the bar to improve external routing appearance and internal routing compatibility.

New Low Viscosity Oil

The inside of the brake system is changing too, with a new low-viscosity mineral oil and new seals to match. The new oil is said to maintain a more consistent viscosity over a wide temperature range, keeping the brake bite point more consistent. Shimano admits that wandering bite point can be an issue with their brakes, but there are many causes. As brake power increases, feedback from the system also increases, and a sharp bite point makes it more noticeable.

To remedy this, there is a new seal at the caliper, which Shimano claims is the hardest part of making a brake. The seals on DOT fluid brakes are mandated by regulations. On mineral oil brakes, though, you’re on your own. The seals need to match the fluid, and Shimano claims that both the seals and the new low-viscosity oil offer more consistency with the flattest temperature-induced change curve on the market. During blind testing, Shimano test riders gave the new brakes with LV oil 3 stars versus just one (for the amount of change) or two (for the frequency of change) for the previous brakes and fluid.

It’s important to note that the new low viscosity oil will NOT work with previous brakes. It will seem like it works at first, but under hot riding conditions, you’ll lose braking power. The two fluids will have different colors to differentiate them, with the new LV Oil coming in orange.

While there is a new brake fluid, the bleed kit itself remains the same. You also don’t have to worry about cross-contamination between the two mineral oils. You can empty the bleed kit, and refill it with the other fluid and bleed a different brake without having to thoroughly clean it first. The same goes for the brake itself – if you accidentally bleed a brake with the wrong fluid, you can simply drain the brake and rebleed it with the correct fluid.

Quieter brakes

Shimano has also fixed another brake annoyance – rattling pads. Believe it or not, the noise on previous brakes comes from the retaining pin hitting the backing plate hole. The new brake pads are wider, with an ovalized pin hole to prevent any noise.

Brake Models for XC, Trail, or Enduro

There are technically three different brake options with the new XTR group, from XC to Enduro. All of the brakes get a new resin piston material for increased durability, and new seals to work with the LV oil.

At the top of the braking power lineup, the full M9220 Enduro brake features the new lever with the new four-piston caliper.

For trail bikes, or those who want more brake power with lighter weight, there is the option of an M9220 lever paired with a dual-piston M9200 XC brake caliper. The interesting thing here is that adding power at the lever is lighter than adding it at the caliper, and it’s even lighter than going up a rotor size.

Then, for XC bikes, the M9200 brake was already one of the lightest on the market, and Shimano didn’t find a way to make it any lighter, but they have updated it with the new seals, fluid, and a new resin piston material.

New wheels with new hubs

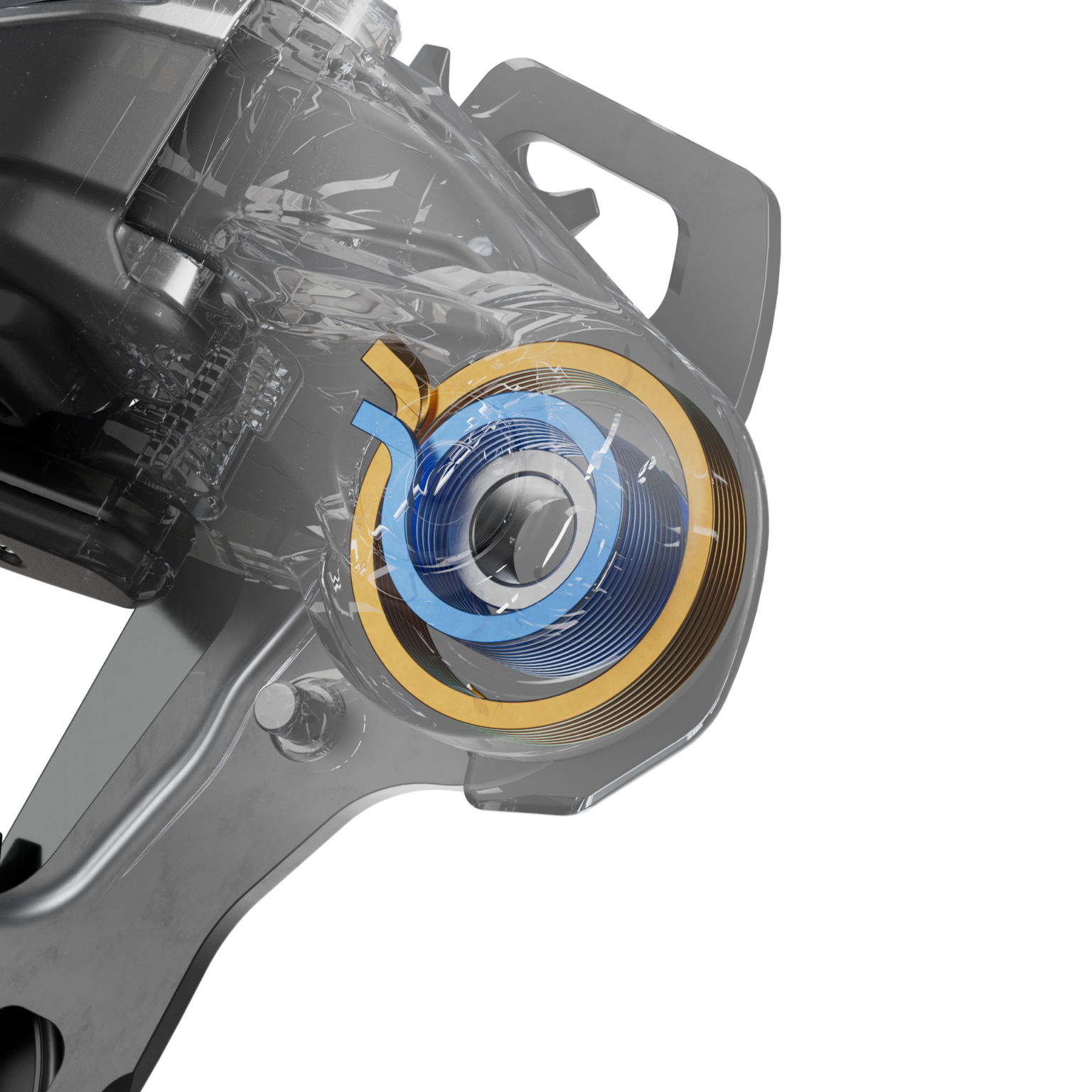

In spite of Shimano developing another new Scylence hub, they claim their skunk riders mostly preferred quicker engagement and low drag. Apparently, their Scylence hubs have to be very well sealed and clean to work optimally, and at that point, the drag is enough to justify a more traditional hub design.

As a result, there are new ‘Low Drag Hubs’ built with industrial cartridge bearings and “low-drag Shimano quality seals.” The latter part includes a labyrinth seal to protect standard cartridge bearings, and two seals and two snap rings that hold the cassette body in place. The design is said to be easy to service, and offers 3.5º of engagement, which is almost half of the current 6.7º of the Shimano FHM9120B hub, while dropping 7g (121g front, 231g rear) and increasing the rotation torque of the hub.

XC or Enduro Wheels

You’ll find those hubs on either the new M9200 XC or M9220 Enduro wheels. The XC wheelset is sub-1200g (1,157g claimed) with a full-carbon 29.6mm internal offset rim (with a slight hook) built with titanium spokes and lightweight rim tape.

The Enduro wheelset also uses a full-carbon rim, but moves to a hookless design with a 30mm internal width, and a 4mm thick rim wall for greater impact strength and flat resistance. It uses standard J-bend spokes, and an asymmetrical rim profile with a centered tire channel for easier tire installation. Claimed weight on the enduro wheels is 1,791g for the set.

Aftermarket Upgrade Kits for existing bikes

One of the best parts of the new group is that it’s backward compatible with a lot of existing Shimano parts, which means you don’t need to buy everything if you want to upgrade. To help facilitate that, Shimano is offering Upgrade Kits for both the drivetrain and the brakes.

The Di2 Drivetrain Upgrade Kit will include a rear derailleur, shifter, battery, battery charger, and a 12s Quicklink and will sell for $985. Not bad for Shimano’s top-of-the-line group. Shimano points out that this will be available full-time, not just at the time of the launch. There are also four versions of the upgrade kit with a choice of SGS 10-51t or GS 9-45t derailleurs, and I-Spec EV or Band Clamp shifter mounts. Everything will ship in a nice presentation box made from easily recycled paper and cardboard.

The disc brake upgrade kits will include right and left brake levers, front and rear calipers and hoses, metal brake pads installed and additional resin pads included, and 100ml of the new low viscosity oil. The brake upgrade kits will only be offered in the four-piston enduro brake spec and are priced at $670.

Availability

The best part? All of the XTR components will be available at launch from OEM partner brands and Shimano Dealers. Time to order your new group.

What about mechanical XTR?

Shimano is not releasing a mechanical version of XTR along with the new Di2 group. When asked if this was the end of mechanical XTR, Shimano didn’t say that it was, but they also didn’t confirm that there would ever be a new mechanical group. For now, the M9100 XTR mechanical group remains available, and will hopefully get even more affordable with the launch of Di2.

Shimano XTR Di2 Wireless Component, New Brake, and Wheel Details

RD-M9250 – Wireless Rear Derailleur

- SHIMANO SHADOW ES Technology

- Precise wireless shifting

- Robust structure with skid plate design

- Solid pulley construction

- Removable and rechargeable onboard battery

- Long Cage RD-M9250 SGS for use with 10-51T Cassette

- Mid Cage RD-M9250 GS for use with 9-45T Cassette

SW-M9250IR – Di2 Shifter Switch

- SHIMANO RAPID ES technology

- Precise wireless shifting

- Tactile feel with each shift

- Multiple shift modes, including hold-down multi-shift, click-through double shift, or locked-out single shift

- Four-way paddle adjust

- Programmable third button on shifter for added customization – like controlling your bike computer or controlling FREE SHIFT and AUTO SHIFT functions through the E-TUBE app

- I-SPEC EV and clamp band options

RD-M9260 – Rear Derailleur for E-MTB

- SHIMANO SHADOW ES Technology

- Wired rear derailleur for E-MTB

- Constant power supply from e-bike battery

- AUTO SHIFT technology

- FREE SHIFT technology

- Long Cage SGS

- 12-Speed RD-M926012 for HYPERGLIDE+

- 11-Speed RD-M926011L for LINKGLIDE

CS-M9200-12 – Cassette Options

- Smoother, more durable shifting under load

- 12-Speed HYPERGLIDE+

- MICRO SPLINE

- Optimized for lightweight and durability

- Cassette Options: 9-45T and 10-51T

FC-M9220 – Trail/Enduro Crank

- High-durability crankset for Trail/Enduro

- Enduro-specific spindle ensures stiff power transfer and impact resistance

- Proven HOLLOWTECH II construction

- Standard 176mm Q-Factor

- Crank Arm Length: 160, 165, 170, 175mm

- Chainline: 55mm

FC-M9200 – XC Crank

- Lightweight crankset for XC riding and racing

- Proven HOLLOWTECH II construction

- XC-friendly 168mm Q-Factor

- Crank Arm Length: 165, 170, 175mm

- Chainline: 55mm

BL-M9220 – Enduro / Trail Brake Lever

- ERGO FLOW Technology

- Smooth SERVOWAVE power curve

- Low-viscosity oil that remains stable over a wider temperature range

- Closer pivot point and upswept lever blade for natural braking motion

- New reach adjust dial on lever body

- I-SPEC EV compatible

- Durable alloy lever blade

BR-M9220 – Enduro / Trail Brake Caliper

- Dual diameter 4-piston design

- Anti-rattle finned pad design

- Low-viscosity hydraulic brake fluid

- Caliper seals with consistent rebound speed

- One-piece caliper design for optimized rigidity and weight

BL-M9200 – XC Brake Lever

- Lightweight construction with carbon lever blade

- Magnesium master cylinder

- Low-viscosity hydraulic brake fluid

- I-SPEC EV compatible

BR-M9200 – XC Brake Caliper

- Lightweight 2-piston design

- Heat-resistant resin piston

- Low-viscosity hydraulic brake fluid

- Post mount

- Caliper seals with consistent rebound speed

WH-M9220 – Enduro / Trail Wheels

- Durable 29-inch carbon tubeless rim

- Hookless rim with 30mm internal width to prevent deformation and punctures

- Durable stainless-steel spokes

- 28-hole conventional structure

- 3.5-degree engagement angle

- Lower drag while coasting

- MICRO SPLINE

- CENTERLOCK disc brake

WH-M9200 – Lightweight XC Wheels

- Lightweight 29-inch carbon tubeless rim

- Hooked rim with 29.6mm internal width

- Lightweight titanium spokes

- 24-hole straight spoke structure

- 3.5-degree engagement angle

- Lower drag while coasting

- MICRO SPLINE

- CENTERLOCK disc brake

Want actual weights and more pricing info? Of course you do: check it out here.