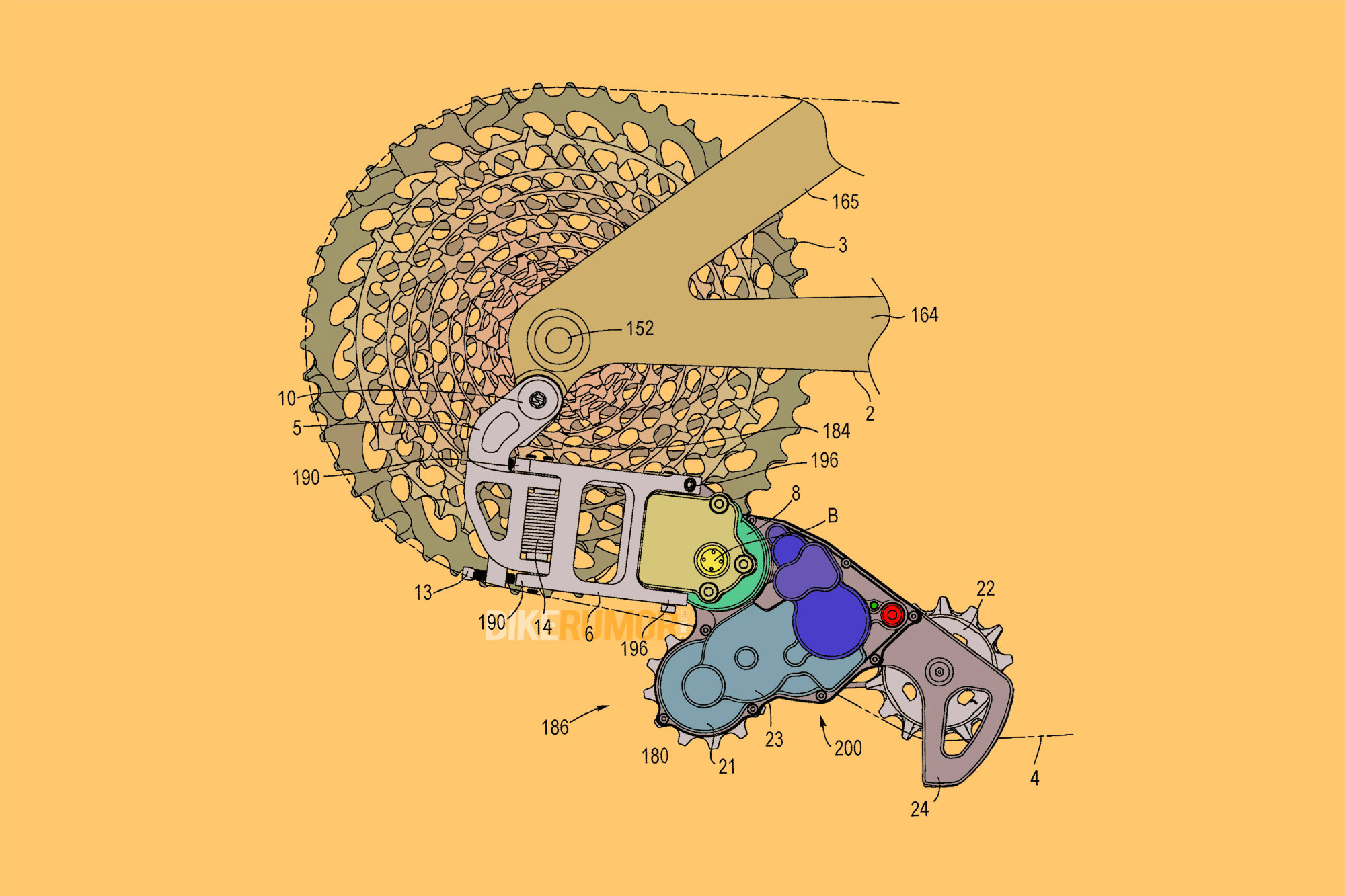

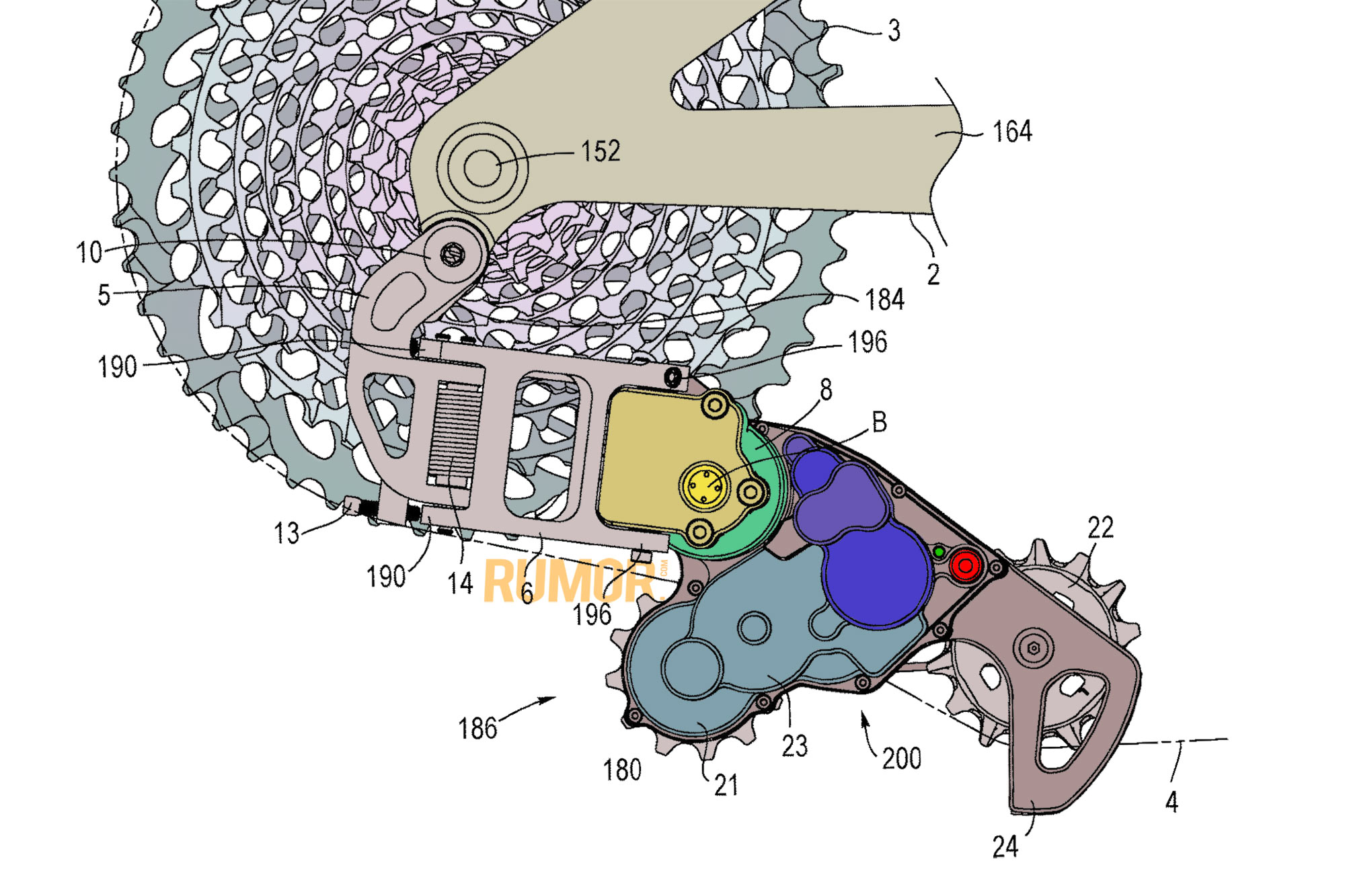

Will SRAM soon debut a self-charging wireless mountain bike derailleur with a dynamo generator inside? Their patent application, published on November 10th, 2022, details an electronic rear derailleur with the means to re-charge itself whilst in use, negating the need for even a medium-sized removable battery that requires charging off-the-bike. The 28-page document describes the use of a generator coupled to the derailleur cage that can be activated to continually charge the batteries by virtue of the rotation of the upper pulley wheel while pedaling.

An on-board energy-harvesting system would certainly reduce pre-ride faff associated with charging removable batteries. It would also make any future SRAM AXS drivetrain carrying the technology a viable option for ultra long-distance endurance racers who now otherwise have to carry spare batteries. However, one can imagine that the mechanism described would result in some loss of watts from additional drag within the drivetrain, given that it is taking its energy from rotation of the upper pulley wheel during pedaling.

We certainly shan’t be estimating how many watts, but we will give you an overview of some of the novelties described in this rather unusual-looking derailleur that may or may not make it to production. Here’s a closer look at SRAM’s Self-Charging Auto-Shifting Rear Derailleur.

Feature images annotated by Cory Benson

SRAM’s Self-Charging Rear Derailleur Concept

The patent in question (US 20220355900 A1) details a bicycle derailleur that incorporates an energy-harvesting system. The first few paragraphs mention one of the drawbacks of current electronic derailleurs; the inconvenience of having to recharge the battery, with the inherent risk of it running out of juice whilst out on a long bike ride. Those lucky enough to own an electronic shifting drivetrain will know this all too well; perhaps not so much because they’ve run out of charge mid-ride, but more likely because they’ve forgotten to re-charge the battery before heading out for their next ride. One can imagine the frustration.

SRAM’s patent published last November describes a self-charging derailleur that would eliminate this issue, meaning its owner would no longer have to fret over the charge state of the battery. They could use that mental bandwidth to fret over more important things, like hydration, fueling, and remembering their loved ones’ birthdays, for example. (Ed’s note: We feel like J-M may have recently missed an important birthday!)

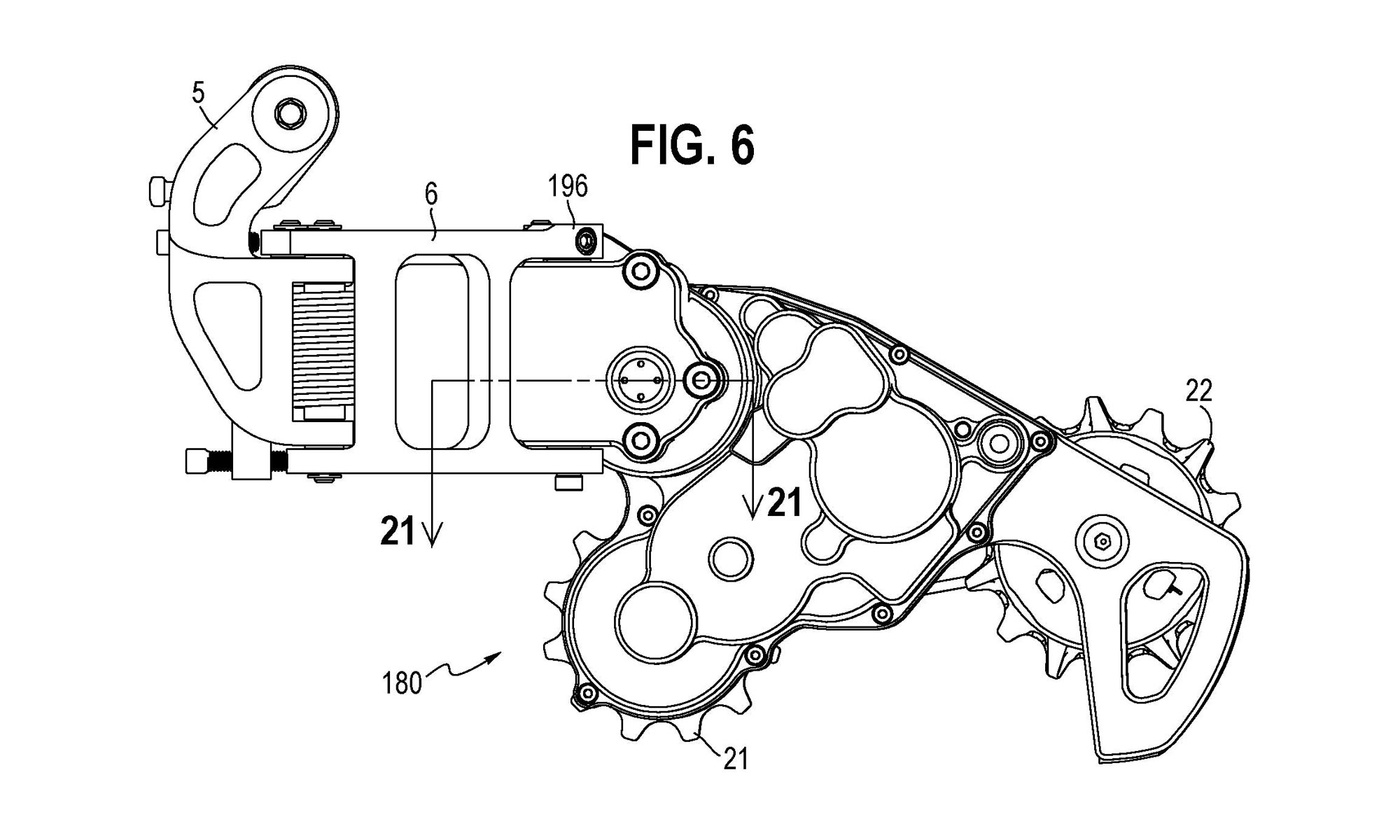

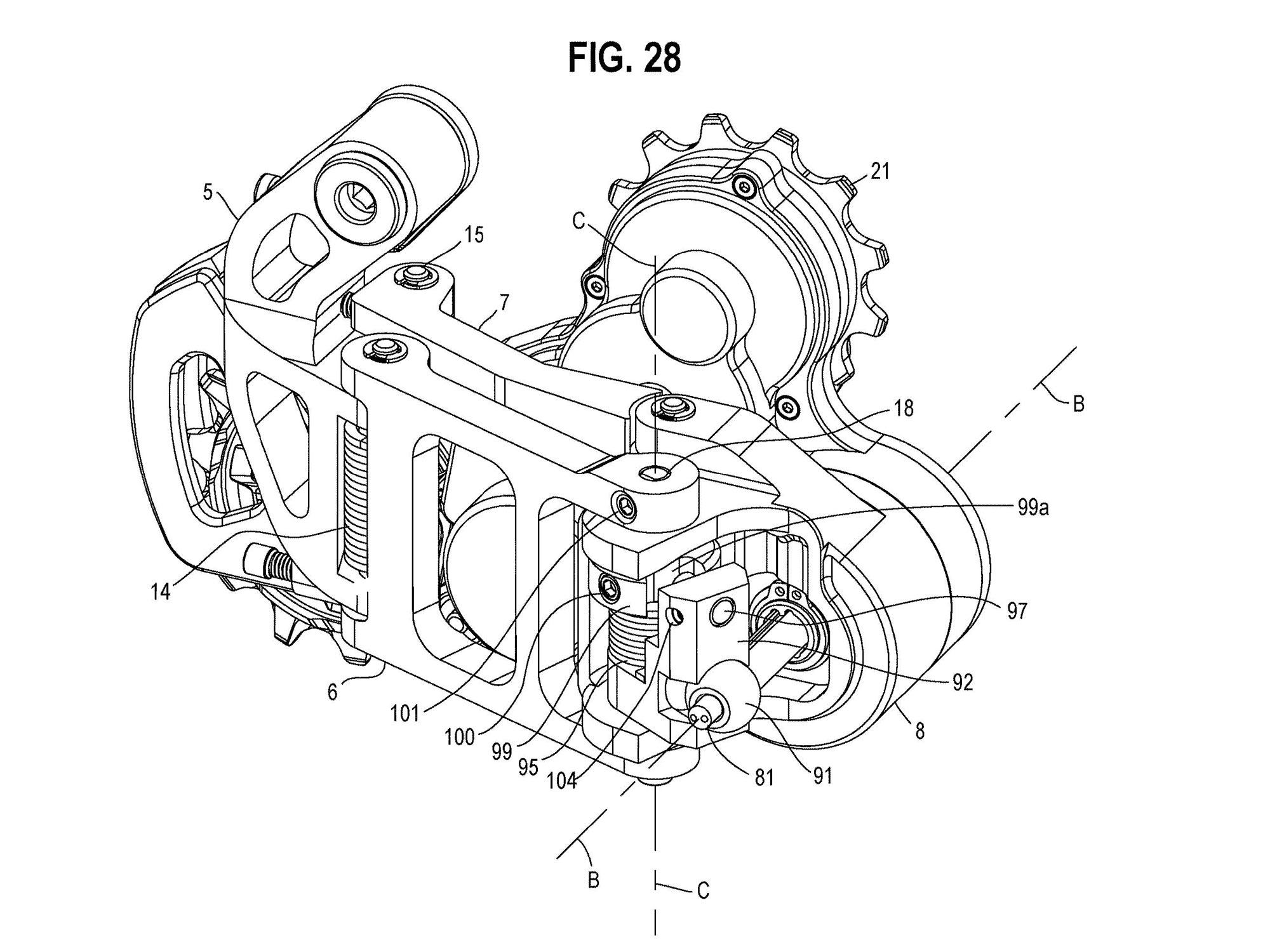

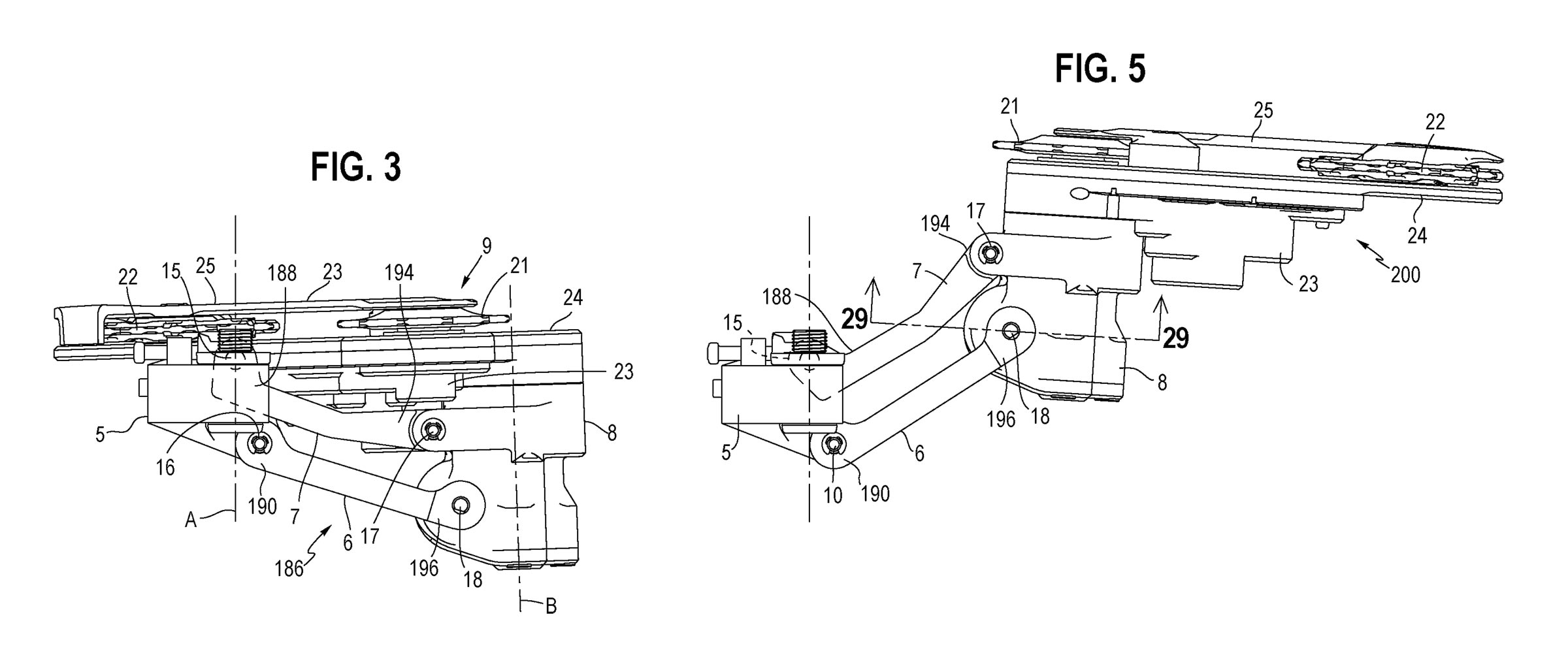

The derailleur depicted throughout the document looks to be extremely compact. The electrical generator system, clutch, motor, shifting electronics and batteries are all housed on the derailleur cage assembly (instead of their current location, further aft on the b-knuckle), coupled to the rotation of the upper guide pulley. That makes for a very peculiar-looking derailleur cage indeed, but also (I imagine) a rather expensive one, too, should it ever need to be replaced.

So, how does it work?

Like most patents, this one details a number of different ways in which it might achieve its primary goal, taking care to assure the reader that the mechanisms described within “are not intended to limit the scope” of the invention. The main embodiment describes the use of a generator that is housed on the derailleur’s cage assembly, which can be activated via a number of different mechanisms in order to re-charge a battery or batteries.

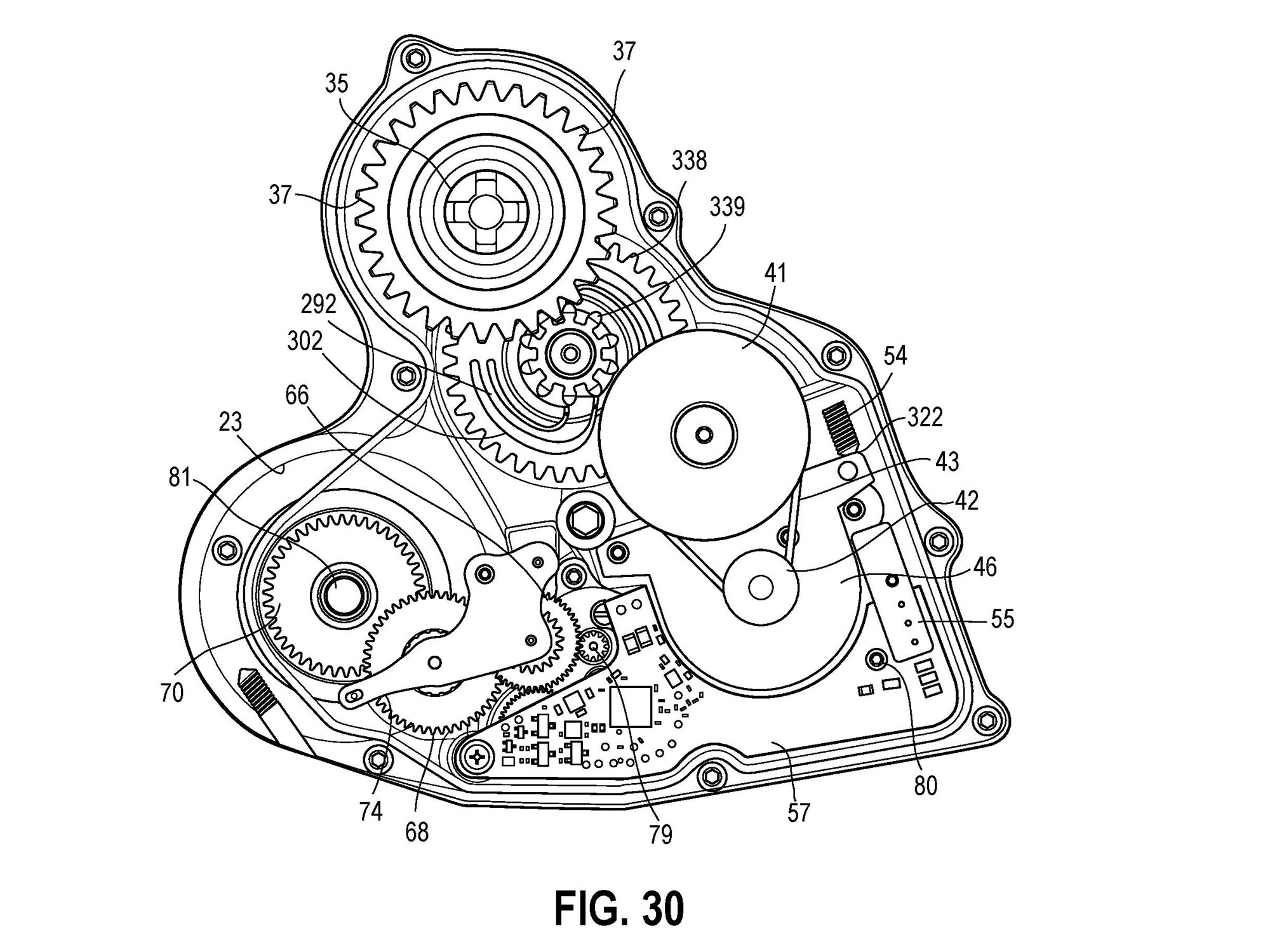

The main mechanism described entails coupling rotation of the cage’s upper pulley wheel (via 35 in Fig. 30), to drive a pinion gear to activate a generator. Within that mechanism, the patent describes use of a spur gear (339), pinion gear (338), belt, and an internal pulley wheel (41) to activate the generator base (46), stating a preferred gear ratio of 33.75:1. So, for every single rotation of the cage’s upper pulley wheel, the pinion gear inside the electrical generator system rotates 33.75 times. That would suggest that the generator is most efficient at very high speeds.

In this scenario an, albeit very small, portion of the rider’s input at the cranks is being used to turn the generator. So, it is reasonable to assume that some of your precious watts will be lost to the electrical generator system in order to charge the derailleur’s battery while pedaling. That said, we imagine that loss to be much less than the losses associated with a larger hub dynamo.

The patent also describes use of a clutch (290) within the electrical generator system that prevents rotation of the gears when the rider back-pedals. Obviously, such a scenario is not so common, but it does occasionally happen to varying degrees on some full suspension mountain bikes during pedal kickback events that result from chain growth.

The patent’s 22 pages detail use of transistors, resistors, and capacitors, the functions of which I shan’t pretend to understand beyond providing a clean flow of electrons to make the battery happy. But, the long and the short of it is this: the on-board generator is, in some way, recharging the derailleur’s batteries so that it, theoretically, should never run out of charge whilst on a ride. This could be a game-changer for the ultra-distance contingent who can’t run the risk of a battery losing charge mid-adventure or endurance race, for fear of having to single-speed it until they arrive at their next refueling spot.

New Shifting Mechanics

Fig. 28 of the SRAM Patent Application reveals completely new shifting mechanics, too. On the current SRAM AXS rear derailleurs, the shifter motor and battery are housed on the aft b-knuckle of the derailleur, in between the rear pivots of the parallelogram linkage that mediate shifts. Here, on the new self-charging electronic derailleur concept, the shifter motor is housed on the cage assembly, sequentially driving pinion gears, spur gears, a screw (81), a nut (91), and eventually a drive pin (97), to rotate the outboard link (6) of the parallelogram in order to execute a shift.

Sorry, you shan’t be getting any more detail out of me than that. However, should you wish to immerse yourself in the mechanics of it all, I can confirm it is all painstakingly spelled out on pages 8 and 9.

It strikes us that a lot of important (and likely expensive) componentry is positioned on the, arguably, more vulnerable part of the derailleur – the cage. Despite this, the patent document reads, “the motor and/or the electrical generator system may be mounted on and moveable [sic] with the cage. If damaged, the cage, including the motor and electrical generator system, may be quickly and easily replaced without having to replace the other components of the derailleur”.

We’ll call the modular replacement concept a consolation prize.

When in the small cog/big gear, that bigger mechanism on the cage does stick out quite far from the plane where the derailleur hanger bolt contacts your frame (15 below). But as you shift into an easier gear/bigger cog, the bulk of the derailleur does appear to tuck up under the chainstay, staying close to the cassette.

Finally, an auto-shift function is also described. Diodes and resistors within the electrical generator system are used to sense the speed of the generator, which could then be used to determine the speed of the chain pulley, and therefore the speed of the chain. That information, taken together with information delivered by other sensors on the bike (at the cranks and rear wheel, for example) could be “used to perform an automatic shifting algorithm which keeps the gear ratio at a preferable ratio for the rider”.

Will the SRAM Self-Charging Derailleur Make it to Production?

Who knows. We approached SRAM for comment on the proposed technology. Their reply? “No comment”, of course. We will keep you updated should we learn more in due course.

The worst-kept secret in the bike industry right now would have to be the imminent arrival of a new SRAM AXS XX drivetrain. We have covered this extensively as various Black Box Prototypes have cropped up on Pros’ Cross-Country Race Bikes. Comparing those photos with the diagrams seen here, it is very unlikely any of the self-charging technology described herein will be a feature of that drivetrain. We reckon it will be several years before we see anything like this rolled out to production, if at all.