We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. Hit the link at the bottom of the post to submit your own question.

Choosing tires can be an absolute minefield. To ensure we’re making the right choice, we must tread carefully, combing through the various casings, tread patterns and rubber compound options. Grip, puncture resistance and rolling resistance hang in the balance, but how a tire’s suppleness impacts these factors is often easily overlooked.

This week, we have ONZA, Maxxis, WTB and Vittoria on hand, answering your technical questions on how TPI relates to a tire’s puncture resistance, as well as its suppleness on the trail. Plus, we have a not entirely unrelated bonus question on safe tire-rim width combinations. Enjoy!

Your expert contributors are as follows:

- Ken Avery, SVP Product Development at Vittoria Industries North America

- James Heaton and Clayton Wangbichler, Marketing and Public Relations at WTB

- Aaron Chamberlain, MTB Marketing Manager at Maxxis

- Robin Schaub, Design Engineer at ONZA Tires

Is it true that a 120 TPI tire is easier to puncture than a 60 TPI tire, as the fibers are narrower?

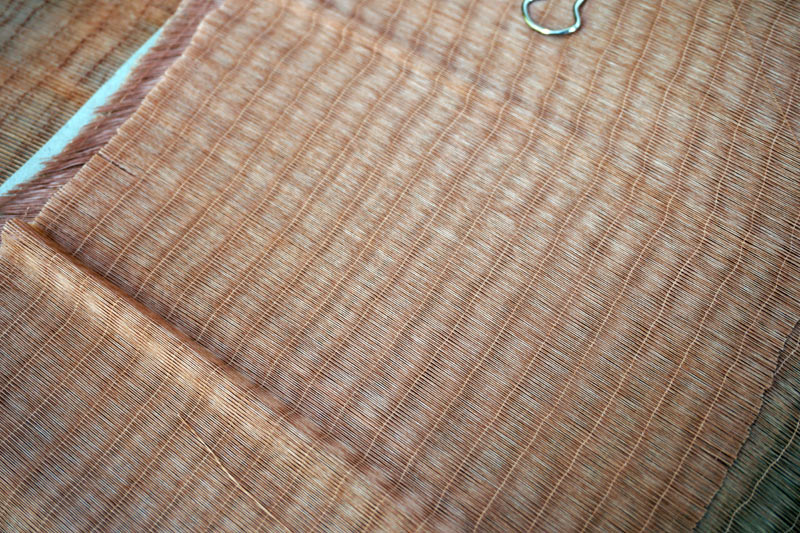

ONZA: For this question we have to dive a bit further into the definition of TPI and the respective connected casing material. Tire casings are made from a woven fabric which consists of nylon threads; TPI is an acronym for threads per inch, meaning it measures the density of the woven fabric based on how many threads there are per inch.

So, in theory, a 120 TPI fabric is twice as dense as a 60 TPI fabric, but in reality, however, the treads used for a 60 TPI casing are much thicker than on a 120 TPI casing which means that it is a lot less fragile and more resistant to cuts.

The wider spacing on 60TPI treads, however, need a much higher rubber penetration in production to be air tight for tubeless setups. This adds additional weight to the tire, but also higher puncture protection due to the thicker rubber coating compared to 120TPI fabrics.

Maxxis: Yes, all else being equal, a 120 TPI tire will be relatively more “fragile” than a 60 TPI tire. TPI refers to the number of threads in one square inch of material. To get more threads into that defined space, each individual thread much be smaller.

One important thing to note: Maxxis measures TPI based on a single ply of casing material, while some brands measure TPI based on a completed tire where the casing material overlaps. So, for instance, a brand may claim 180 TPI when it’s really the same piece of 60 TPI casing folded over on itself twice (60+60+60), creating three layers. It’s like folding a $20 in half and claiming you now have $40.

Vittoria: There are many factors that contribute to the durability of a tire, and casing TPI is certainly one of those factors. However, when considering a tire, TPI must be viewed along with tread thickness, compound, aspect ratio, etc., which all work together to prevent punctures.

For the sake of the question, if you are simply comparing a higher TPI material (such as 120) to a standard TPI (such as 60) material, the higher TPI does provide less protection, particularly in terms of impact resistance. This is due to the cord thickness being smaller (more threads fit into one inch), which typically sacrifices a bit of abrasion resistance for higher flexibility and lower weight.

In applications where lower rolling resistance and weight are the key goals, higher TPI will typically be used. In applications where durability comes first, lower TPI may be used. It all comes down to the intended use of the tire, and what the project goals are. Often times you will see a higher TPI used with additional sidewall protection, which offers a balance of both traits.

WTB: If there is no puncture protection layer added to the casing, then in theory, a tire with a 120 TPI casing would puncture a little easier than a 60 TPI tire. The fibres that make up a 120 TPI tire casing are thinner than those of a 60 TPI tire, which means there is less rubber holding it all together. A thinner casing with less rubber would, theoretically, be more vulnerable.

However, we build a nylon puncture protection layer into all our 120 TPI mountain and gravel tires. This way you can benefit from the reduced weight and increased suppleness that a higher TPI has to offer, without compromising on durability.

How does TPI affect tire casing suppleness?

WTB: Theoretically speaking, a tire with a higher TPI count should be more supple. The thinner fibres combined with less rubber will result in an overall thinner casing that’s able to flex and conform to terrain better, giving a more supple feel.

In the real world though, a lot of off-road 120 TPI tires are accompanied by a puncture protection layer, which will vary in form depending on the manufacturer. Adding a protection layer to the casing will inevitably ‘thicken’ it up a little, and then the characteristics of a higher TPI count will be less obvious. The more substantial the puncture protection layer, the more likely that it will affect the suppleness. The thinner the layer, the smaller the effect.

So, to answer the question, having a higher TPI can be more supple, but it really depends on what else is added to the casing during the design process. Finding the right balance of TPI, rubber thickness, and efficient puncture protection is key.

Maxxis: All else being equal, a tire will become more supple as the TPI increases, so a 170 TPI casing is more supple than a 120 TPI which is more supple than a 60 TPI. A supple casing conforms better to the terrain which can improve traction and reduce rolling resistance. Think of the difference between a Hanes Beefy-T and a silk shirt.

ONZA: The TPI count is an important parameter to fine-tune the characteristics of a tire casing. Using the basic TPI knowledge from the previous question, we know that the threads to produce different TPI casing fabrics use diameters. A lower TPI number casing uses a stiff thread, woven into a loose fabric, while a higher TPI number casing means a finer thread woven into a dense fabric, allowing the rubber coating to be reduced to a minimum.

Lower TPI casings will adapt their form with less resistance to the ground underneath the tire, while higher TPI casings provide better damping due to the increased rubber penetration. To illustrate this explanation, let’s compare the fabrics of (A) a robust denim cloth, made of thick cotton strings and (B) a delicate silk fabric, woven of threads as fine as a hair.

A might be more durable, but is less supple than B. This might not make too much of a difference on a single-ply casing where only one (if folded 2) casing layer is used, however when using multiple casing layers such as on more gravity orientated casings for example, casings can become super stiff. This is why we use a 60 TPI casing on our lightweight Cross Country and Trail casings but decided to go for 120 TPI fabric on our gravity casing.

The supple casing morphs a lot better to the ground and therefore offers more grip, while we use a rather high butyl inlay for sidewall stabilization and pinch flat protection.

Vittoria: A higher TPI means that each thread in the casing material is thinner, so more threads fit into a measured inch. Typically, a thinner thread will be more flexible than a thicker thread. Additionally, on a higher TPI tire (with thinner thread) the valleys between each thread will hold less rubber than a casing with a lower TPI (and thicker threads).

Both of these factors effect casing suppleness, and while this may seem overly detailed, the performance effect can be quite noticeable. Higher TPI tires exhibit less rolling resistance, as the casing is more flexible, so it does not deflect off of bumps (causing resistance) as it rolls. A higher TPI casing will also allow for more casing deformation, which allows for a slightly larger contact patch, which then increases traction (especially in off-road applications).

Is it safe to run 2.35”-2.5” tires on a 35mm internal width rim?

Maxxis: This is a question we see A LOT! As wider rims gained popularity a few years ago, Maxxis developed our Wide Trail (WT) tire casings to better pair with 30-35mm wide rims. Basically, our older tires were designed around narrower rims (think 17-20mm internal) and their profile would become very square when used on modern rims.

So, we went back and revised those older treads and of course, any new treads were designed with wider rims in mind from the start. But, to answer your question directly, yes that’s totally fine. A 2.35” on a 35mm rim will work but depending on the exact tire used, it may result in a profile that is squarer than ideal.

And, going in the opposite direction, you can use a modern, wide tire on an older, narrower rim (within reason), but the tire profile will be very round making it difficult to engage the side knobs properly.

ONZA: To ensure constant performance we design all our tires around a specific rim width, i.e. for our 2.4” tires we target a 25-32mm rim size. Although we recommend certain rim widths, running a slightly wider (or narrower) rim does not make for an unsafe ride but it will definitely change how the tire sits on the rim, e.g. it will get a wider, flatter overall profile when you mount it on a wider rim which of course has an influence on the riding characteristics and performance.

Customers can easily find the recommended rim width for their ONZA tire molded into the tire’s sidewall. To answer the original question about the safety of running a 2.35″ – 2.5″ tire on 35mm internal width rims, it can be answered assuredly with “Yes, it is safe!”.

Vittoria: Technically, this ratio is outside of what is recommended in terms of industry standards. The major risk is that the tire bead may come unseated, leading to a failure.

Regardless, a tire that is stretched to this extent will likely not perform as well, as the casing width will have grown disproportionately to the tread, which creates a very square profile. Furthermore, by doing this, the sidewall will be very exposed, and likely lead to increased abrasion.

WTB: Safe is a strong word. Mountain biking isn’t safe. If you’re asking whether tires in the 2.35” – 2.5” range will mount to a 35mm rim securely, then the answer is yes, absolutely. As long as the manufacturer adheres to ETRTO standards, then the fit between the tire’s bead and the rim should remain consistent, regardless of the tire width. That’s not to say it’s recommended though, and here’s why.

Each tire is optimised around a certain rim width. There is a little wiggle room, but we absolutely recommend choosing tyres that are designed to work best with the rims you are running. By doing this, you’ll benefit from both optimum performance, and better sidewall protection.

If you fit a narrow tire to a wider rim then the profile of the tire will be flatter than intended, and the tire won’t ride and grip as well as it could. The same can be said if you fit a wide tire to a narrower rim. You won’t be getting the most out of that tire.

Then, there’s the sidewall side of things. Running a narrower tyre on a wider rim will make the sidewalls ‘stick out’ a bit more than they should. The side knobs of mountain or gravel tires can act as a fantastic sidewall shield when smashing though rocks, but if the sidewall sits at the same width as the side knobs, they’ll be more exposed. For 35mm rims, we’d recommend running tires in the 2.5-2.6″ range as that should give you optimal performance.

You can check our other tire & rim width recommendations here.

Got a question of your own? Click here to use the Ask A Stupid Question form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!