We’ve toured a lot of carbon fiber wheel factories, and most have their secret sauce. But most also use very similar methods of cutting the carbon sheets into shapes, laying them up, and molding them into a wheel.

So it was quite refreshing to see how Forge+Bond makes their wheels. Yes, they start out with a different material – nylon-infused carbon fiber – but that’s only the beginning. From cutting to layup to assembly, their entire process is unlike anything we’ve seen before. And it’s all done right here in the USA!

Here’s how Forge+Bond makes their recyclable carbon fiber road, gravel, and mountain bike rims…

Update: CSS Composites Closing?

Just over a month after posting this tour, it appears that CSS Composites may be closing. As we reported back in 2023, CSS Composites was the parent company of Forge+Bond, utilizing their Fusion Fiber carbon technology outlined here. Currently, it’s unclear what the closure of CSS Composites would mean for Forge+Bond, not to mention all the other brands that build complete wheels with Fusion Fiber rims like Revel, Chris King, Atomik Carbon, Evil, and more. We’re in the process of digging up further detail, so stay tuned.

Video Factory Tour

If TL;DR is your style, the video above has their CEO guiding us through the factory and the process. If you prefer pics and words, or just want to see more details, here’s the story…

Forge+Bond’s factory is tucked away in a tiny town called Gunnison, UT. It’s close to nothing, and their rim manufacturing is spread across two buildings where they also make parts for UTVs and, previously, the aerospace industry. They also make various parts for other outdoor brands, as well as producing rims for Trek/Bontrager and Chris King.

Cutting & Layup

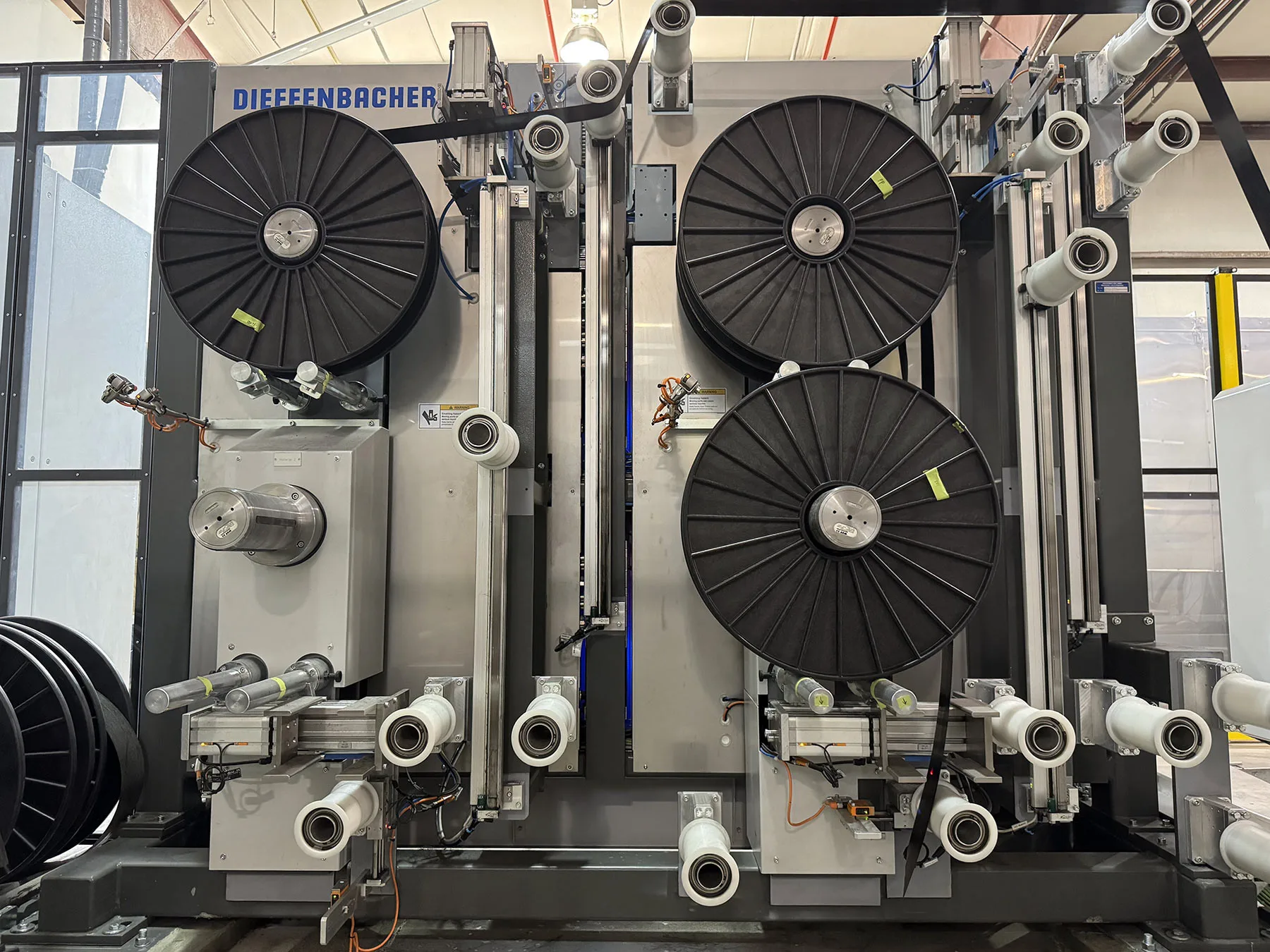

Unlike typical epoxy-impregnated carbon fiber, which comes on large, wide rolls that must be kept in a freezer to prevent the resin from hardening, Forge+Bond’s nylon-infused pre-preg comes on spools and can be kept indefinitely at room temperature.

They’re loaded onto a Dieffenbacher Fiber Forge…

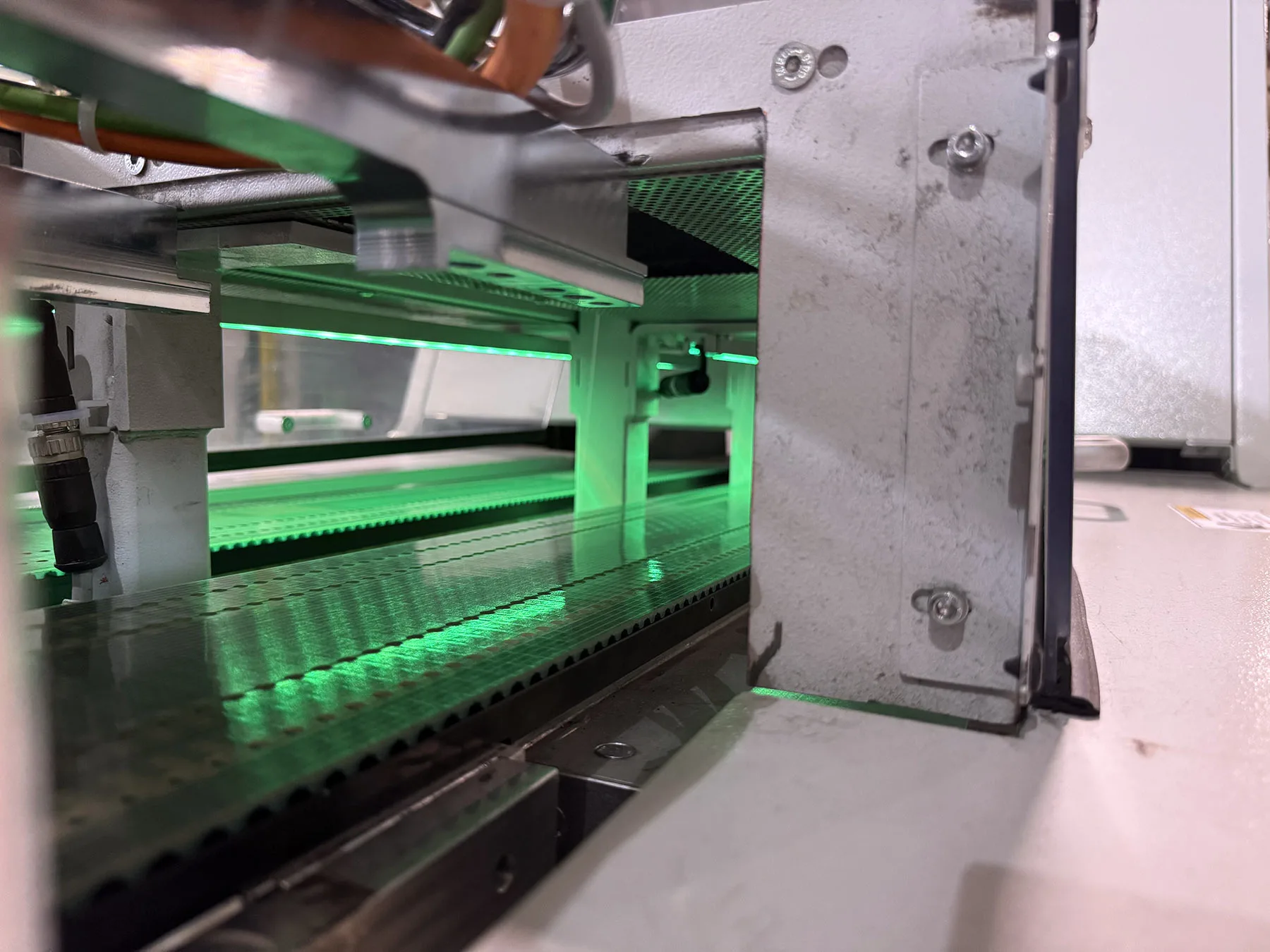

…and the ribbon of carbon fiber runs through this cutter. A rotating head can cut it at any angle from +45º to -45º.

Then it runs through this tunnel on a vacuum-suctioned belt to hold pieces in place as it shoots them into…

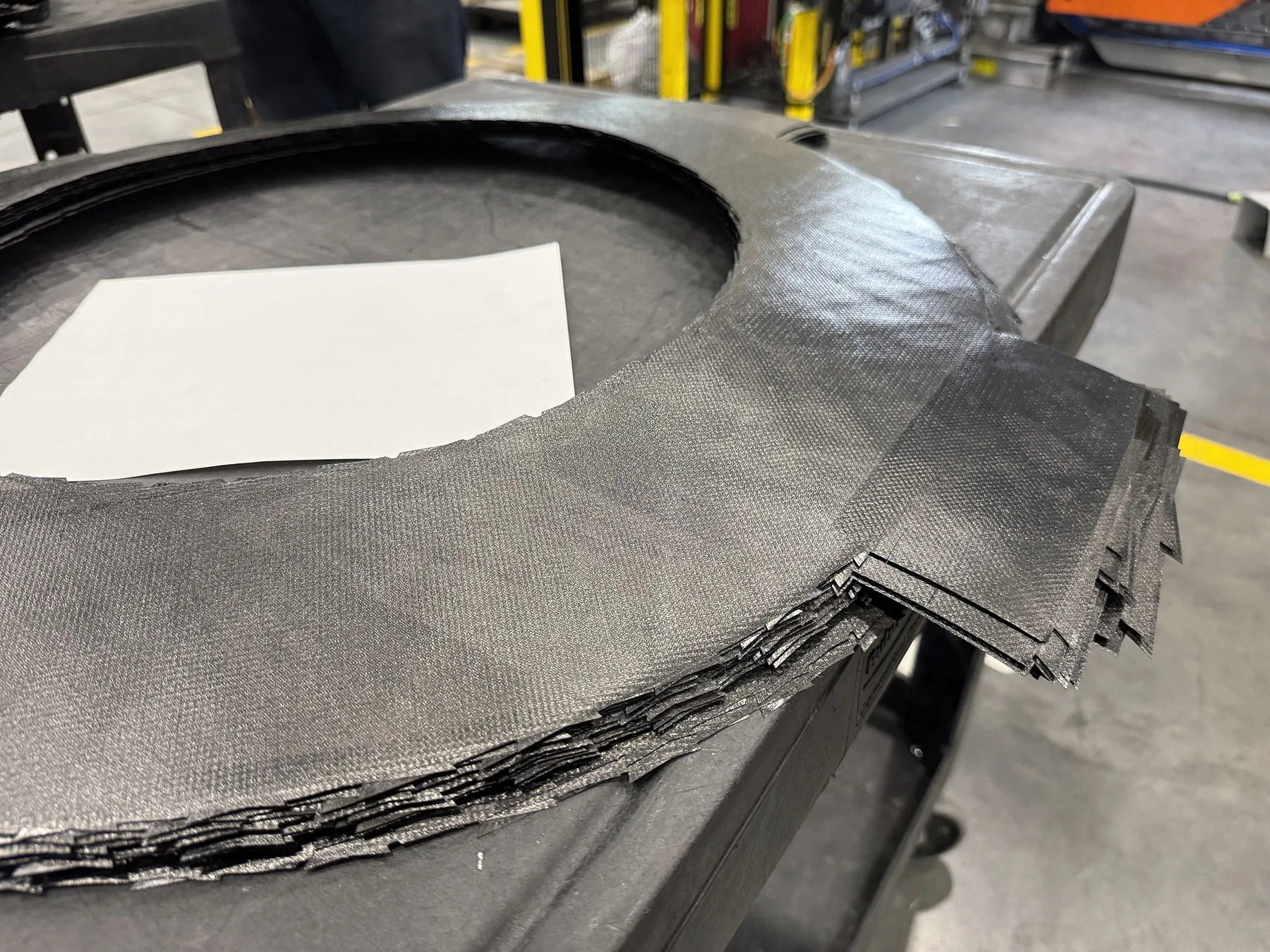

…the layup machine. This giant round metal table pulls a vacuum to hold the first layer into place. Subsequent layers are laid over it and ultrasonically welded to the layer underneath. It keeps getting layered at various angles until it produces this:

This blank is one sidewall of a rim (a 37mm deep road rim, if memory serves).

Note the individual “cards” of carbon fiber. Each layer is cut at different angles to create the desired stiffness, flex, and ride characteristics. That little indent is the ultrasonic weld that tacks the layers into place.

And this is one of the biggest differences in Forge+Bond’s construction method. While many carbon rims use longitudinal sheets to create big panels of carbon fiber, F+B’s smaller pieces let them angle the fibers for a much more consistent ride quality all the way around the rim. Virtually every fiber is at the optimum angle to resist impacts or manage stiffness and compliance at the exact spot where it’s rolling over the ground.

Consolidation & Assembly

This boring-looking machine is the Consolidator. The loose rim sections go in, a vacuum is pulled to flatten it against the glass, then the cartridge (yellow part & lid) swings to the right where it’s heated for just 45 seconds. That melts the thermoplastic just enough to … wait for it … consolidate the part into a single piece.

It then spins around again and cools it in about 90 seconds, then spins out, opens up, and the parts are cool enough to just grab and remove.

The result is a flat, one-piece part (a sidewall, in this case) that’s ready to get shaped:

The large orange press in the back is where the flat, consolidated blanks get pressed into the shape of the sidewall. Those four tabs sticking out? That’s how they clamp it into the press, which then pulls them back to a heating chamber to warm and soften them, also for about 45 seconds, then they slide under the press and are mashed into shape.

The press itself isn’t heated, it’s just pressing the soft, warm carbon into a shape. It holds it there just long enough for it to cool and harden (about another 90 seconds), then it slides out and the part is removed.

Think of it like par-boiling a potato to save time later…the sidewalls now hold their shape so they can be assembled into the final mold with the other parts, but they’re not fully baked yet.

The edges are still rough, too, so these now go to the water jet cutter to be trimmed into the final shape that’ll fit into the mold.

The cutting uses only water. There’s no additional medium (abrasive material) added to the water, so the scrap remains clean and goes straight into a recycling bin:

Because it’s using thermoplastic (fancy nylon) rather than an epoxy resin, the scrap material can be chopped up and re-molded into other items.

We’ve seen tire levers made from them, but Forge+Bond is also using the material to make larger items for other industries where a continuous fiber isn’t required.

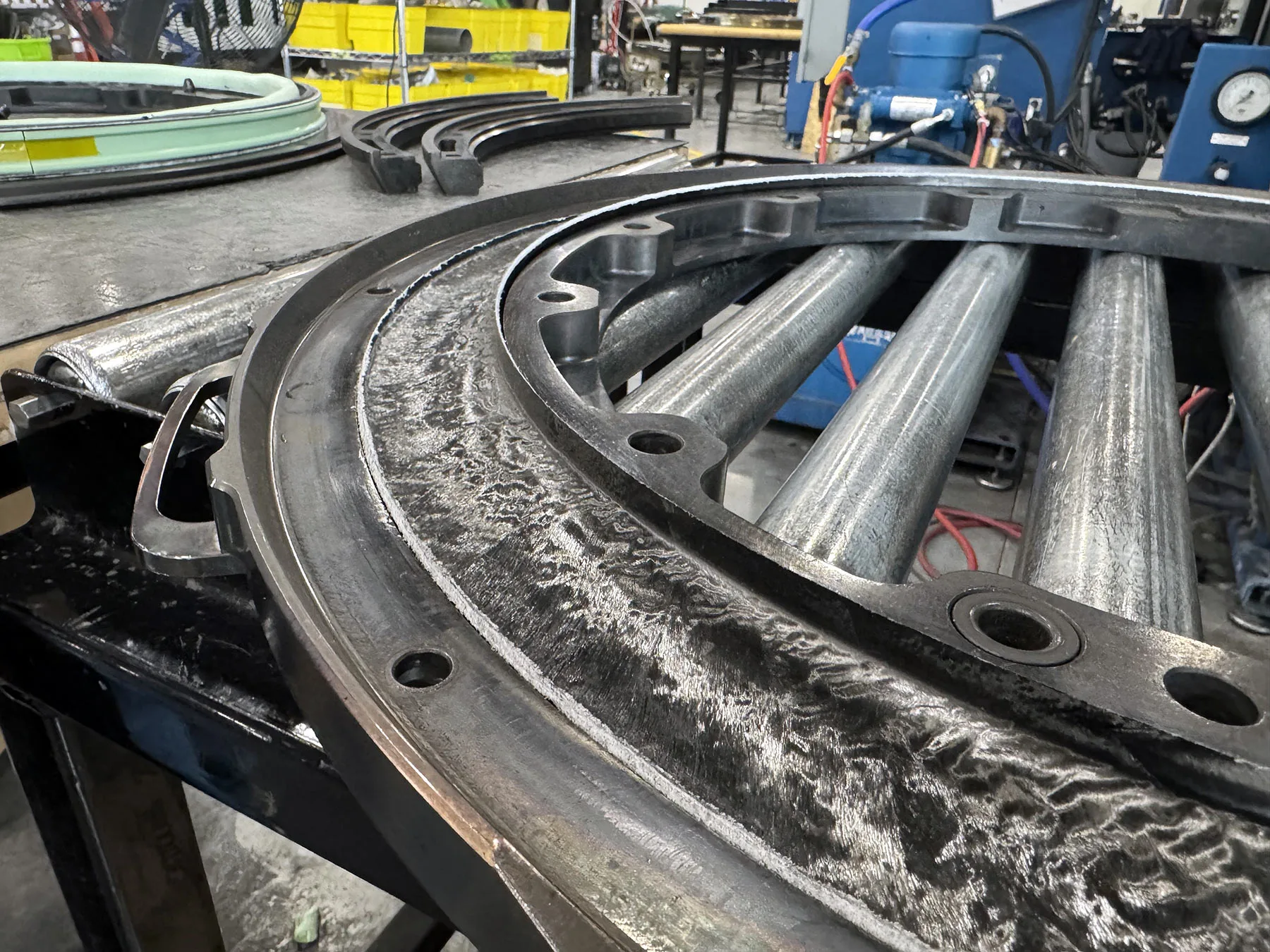

The rim bed is molded with three sections as a single piece…

…then cut out and moved along with the sidewalls to the molding area.

The sidewalls…

…and rim bed channels are queued up…

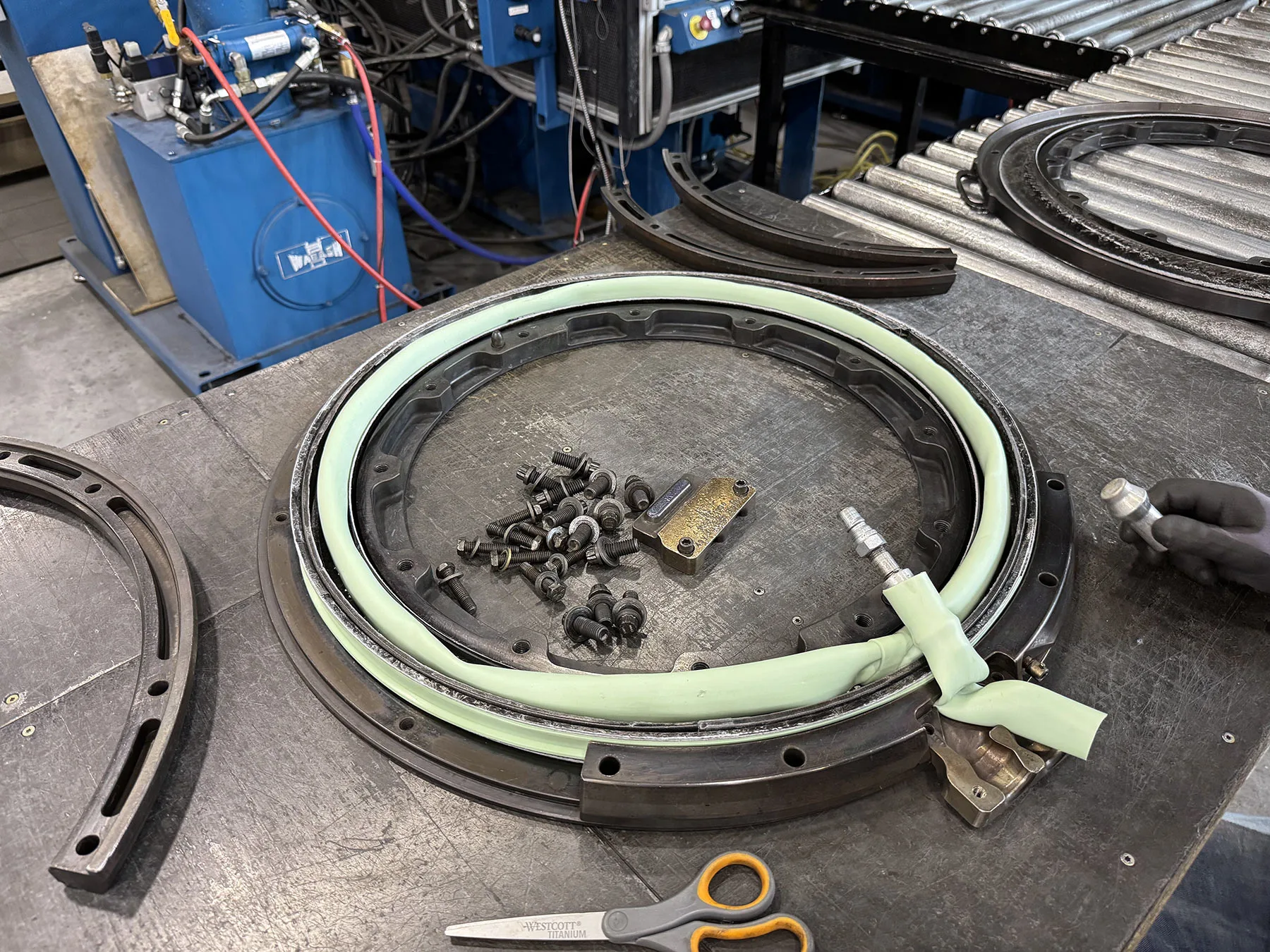

…then laid into molds.

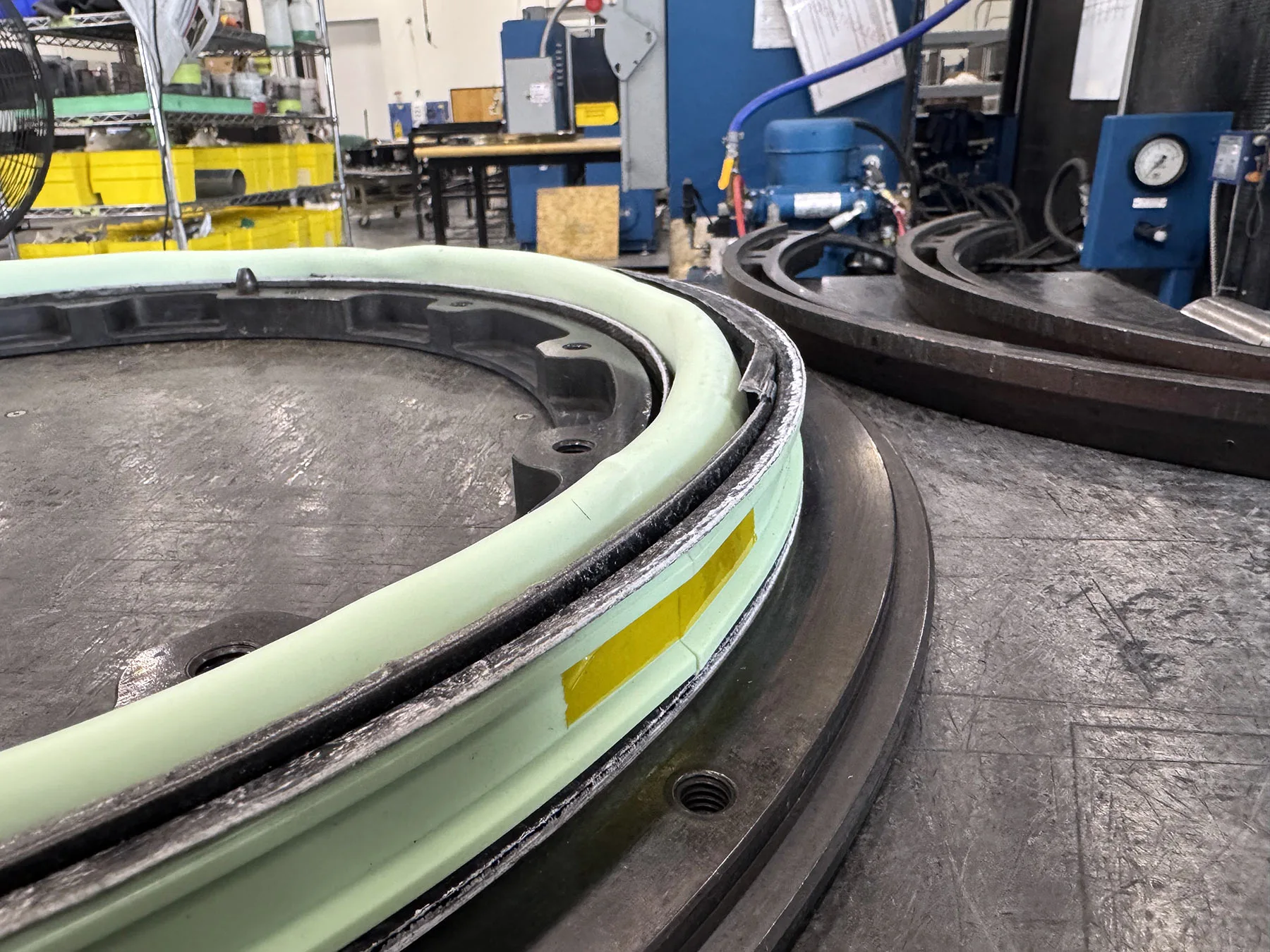

Silicone bladders are laid into the rim bed to shape the tire’s bead seat and internal sidewall. An inflatable bladder is used under the rim bed, between the sidewalls, to create the cavity that gives a rim it’s shape and structure.

Once it’s fully assembled, the top half of the mold (with the other sidewall in it) is placed on top, it’s bolted together, and then hooked up to an air hose to pressurize the bladders. That air pressure pushes the carbon fiber against the hard metal mold to compact it and squeeze out any air and excess thermoplastic resin.

Each rim goes into the heat press on the left, where it’s warmed to a proprietary temperature for a proprietary (but surprisingly short) amount of time. The press itself isn’t putting any pressure on it, that’s all handled by the air pressure inside the mold – it’s only providing the heat to melt the resin and turn the various parts into a single rim.

Once it’s heated, it’s slid over to the right and goes into a cooling press. This brings the temperature back down, and the timing and rate of cooling is another proprietary part of their process. They say controlling all of those factors is what creates a strong rim with the right ride qualities.

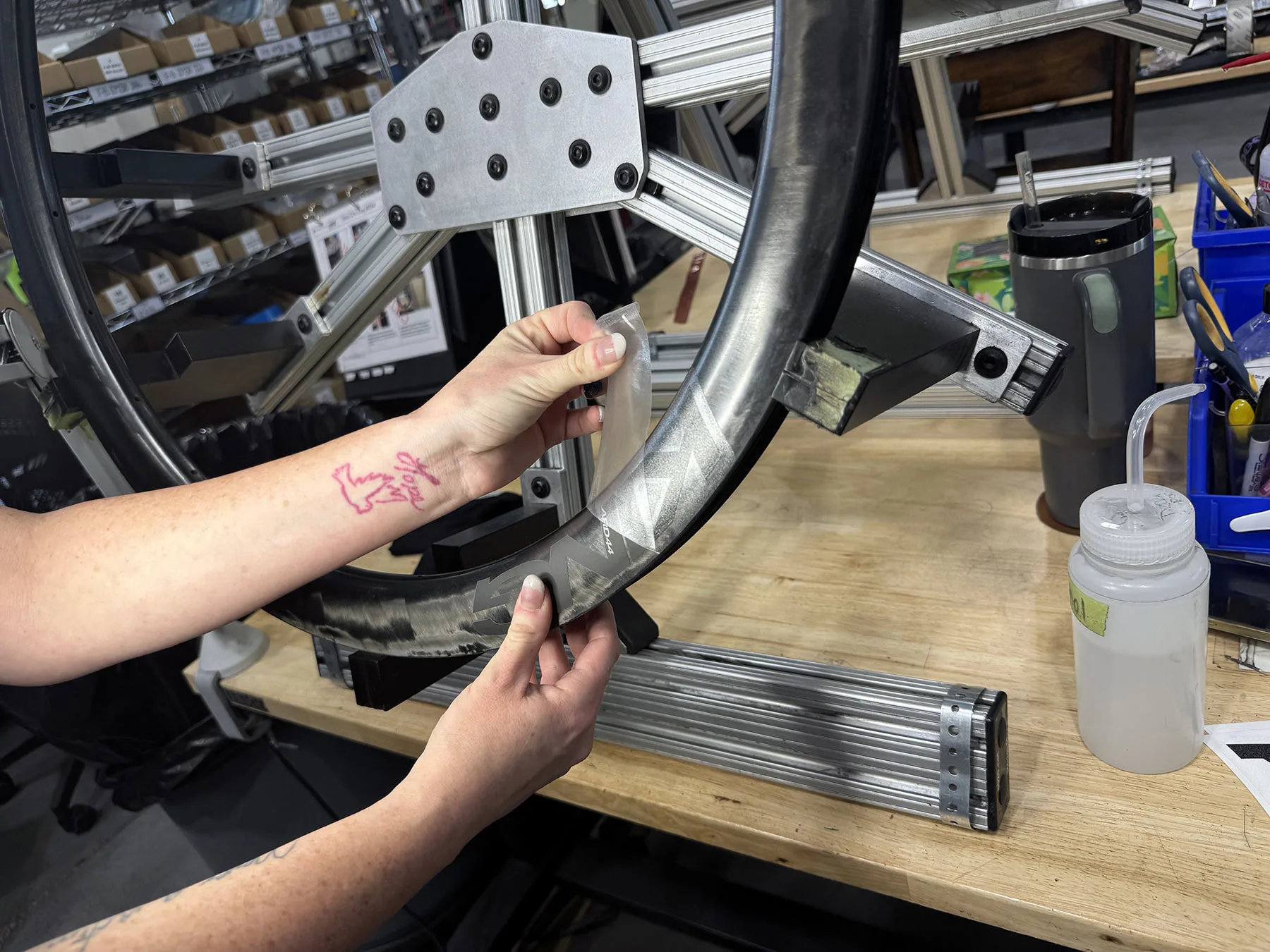

The last steps are trimming off the flashing (excess resin that’s squeezed out) and building them into wheels. For brands like Chris King that build their own wheels in house, the decals are applied and then they’re shipped off to Oregon.

What’s remarkable is the lack of additional finishing work required. There’s no sanding, filling, or painting. The rims come out of the molds perfect, with only the flashing needed to be picked and sanded off. They all go through quality control, of course, but it means there’s no carbon dust flying around or extra work required to get the rims ready to go.

The only additional finishing work required is to drill the spoke and valve holes (done inside an enclosed machine) and patch the hole where the inner silicone tube is pulled out. A thermoplastic carbon panel that matches the shape of the rim bed is bonded into place, then they’re ready to be built.

The level of automation in cutting, laying up, and prepping the rims is truly unique, and likely offers an improved level of consistency and finish quality, too. Overall, we came away really impressed and are looking forward to riding our own set in the near future.