After months of spy shots and speculation, the new direct-mount MTB rear derailleur is here. Far more than just a new mech, it’s an entirely new system called SRAM Transmission.

Three distinct versions — XO, XX, and XX SL — will come as complete groups, and it’s called a “transmission” because everything is interdependent in ways that current “drivetrains” are not. Meaning, with a drivetrain, there are lot of different parts from different brands with different tolerance stacks that could be used together. With a transmission, there’s no mixing or matching — it’s a complete group that’s optimized as a system.

SRAM says (and we’ve all likely experienced) that at a minimum, variations in frames and dropouts have necessitated things like barrel adjusters and fine-tuning during setup. When you start mixing and matching parts across brands, small individual tolerance outliers add up to big differences from bike to bike. That meant parts needed a lot of built-in adjustability, particularly the rear derailleur.

But all those points of adjustment are only there to take up the slack between frames and components. So, SRAM designed a system that eliminated all of that slack and, thus, the adjustments.

Now the freehub body, cassette, and rear derailleur fit together perfectly, automatically and always. So, there are no adjustment screws needed because there are really no more adjustments needed. Just assemble it and it’s perfectly aligned.

But that’s just the beginning …

How SRAM Transmission Sets Up Differently

It began years ago with the UDH (Universal Derailleur Hanger), giving every frame manufacturer a single, well-defined design parameter for rear derailleur placement in relation to the cassette/freehub body. As bike brands updated their frames to use UDH, they were effectively giving their bikes a hanger-less design, and SRAM was busy working on a direct-mount rear derailleur that would take full advantage of that standardized interface.

Before we get too far, you’re probably wondering:

- Yes, all of this new stuff is designed to be used as a complete system.

- No, it’s not compatible with existing Eagle 12-speed parts save for the AXS shifters.

- No, SRAM is not sorry for this — its goal was to create the best possible system.

- All of the drivetrain parts are marked with “T-Type” on them to indicate compatibility.

- In order to run Transmission, you’ll need to use the chainrings, cassette, chain, and derailleur as a group.

- However, it uses new Flat Top MTB chains, which are compatible with Road Flat Top chains.

- So, you can mix T-Type cassettes and derailleurs with current SRAM road 1x cranksets and drop bar AXS shifter levers for a mullet gravel drivetrain, as long as your road/gravel frame is UDH compatible.

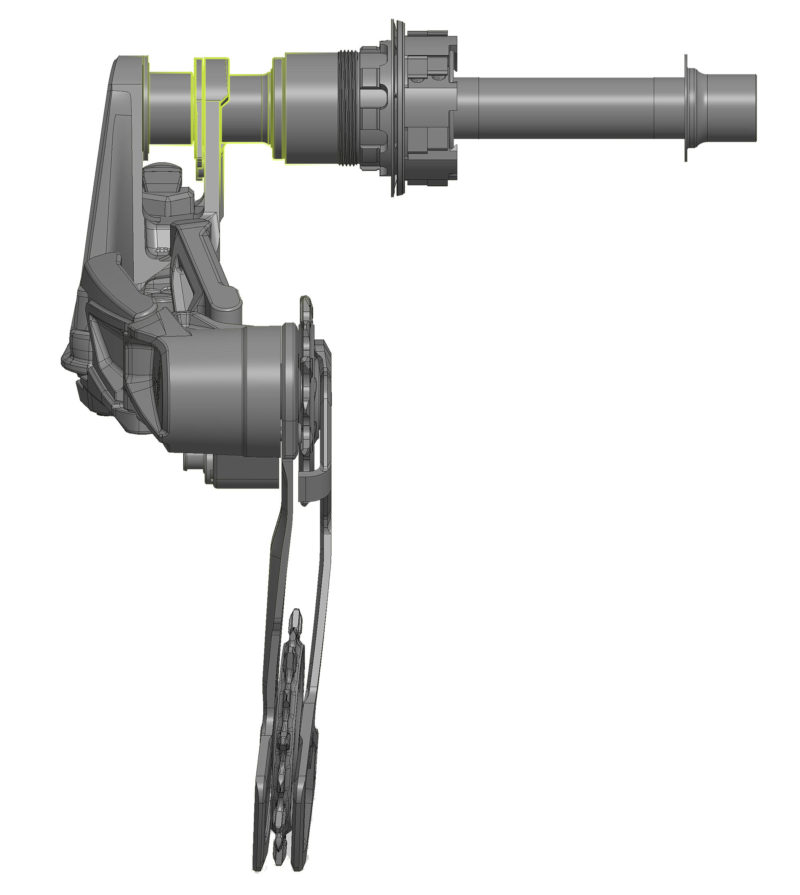

As with most SRAM launches, the new design brings plenty of new nomenclatures. Now, the derailleur’s “Full Mount” slides over the dropout in a “Hangerless Interface,” with the mounting bolt attaching from the outside and threading into an Alignment Plate between the inner mount and the frame.

The Alignment Plate acts like a washer between the derailleur and the frame. Its knurled inner surface grabs onto the frame, while a smoother back allows for derailleur rotation in the event of an impact. The small prongs provide a range of movement used during setup.

There’s no more B-screw to set its position, but there is a “Setup Key” with an A/B position for the Cage Lock that catches an intermediate point on the pulley cage.

This is used for initial installation only, but doubles as the normal Cage Lock pin for holding the pulley cage in an extended position for easy wheel removal.

Your frame’s design will dictate whether you use A or B, and it’s simply a matter of popping the pin housing out, flipping it, and snapping it back into place.

Insert the wheel, thread in the thru-axle, and then shift the derailleur so that the upper pulley is aligned with the “Set Up Cog” (the one with the red plastic guide behind it). Now, with the derailleur cage held in the setup position, you install the chain, which has also been simplified.

Based on warranty information and its consumer interactions, SRAM found three main things that would end rides:

- Bad or forced setup

- Robustness

- Shifting under load

SRAM says AXS reduced these issues by about 25% over cable-actuated systems by eliminating the cables and minimizing the need for limit screws. Transmission eliminates 66% of remaining tolerance issues by removing derailleur hangers and the tolerance variations those bring.

This left chain length as one of the very few areas left for user error, but now there’s an app for that. You could still set up the bike by putting the chain on the big cog and chainring and measuring and adding two links.

Or, you could measure your chainstay length, input your chainring size, and use the AXS app to determine the correct number of links.

Or, because SRAM knows every brand that’s UDH/Hangerless compatible, there’s a drop-down list of frames and you simply choose the bike you have, your chainring size, and it’ll tell you what chain length you need.

No more counting link overlap or pre-sagging your suspension to get the right length.

Then you simply align the mark on the derailleur’s Full Mount with the mark on the washer plate and tighten the mounting bolt. There is a sequence to tightening, then loosening, then retightening the mounting bolt, but it’s easy and SRAM will have a full instructional video for it — and you only need to do that once.

After it’s set up, you can take the wheel on and off without affecting the derailleur’s position. But if you ever change chainring size or remove the derailleur, you’d need to set it up again to get the proper chain gap.

Your derailleur is now installed and perfectly aligned. No more B-screw, no more upper and lower limit screws, and no more using the trim buttons. Since everything’s position in relation to everything else is now standardized, it just goes where it’s supposed to and shifting is perfect.

It’s also a much stronger system. By putting the rear axle all the way through it and supporting it with two mounts, it goes from a single-shear mount to a double-shear. And, it effectively lets the bike’s entire rear triangle act as a system rather than a collection of parts with weak links (i.e. hangers) in the middle.

How much stronger is it? Lots. You can stand on it. Or wreck on it. Or your bike can fall over on it. Not only is the Full Mount incredibly robust, SRAM made it strong enough to withstand any load it’s ever likely to see, and to do it over and over again.

And if you do smash into something and the derailleur rotates backward, you can manually rotate it back until the mark on it lines up with the alignment plate. Or just loosen the rear axle a bit and it should spring back into position on its own.

OK, but What if I Do Break It?

It’s completely rebuildable. Well, mostly. The motor unit and inner parallelogram and lower knuckle are one piece. But, the three parts that are most vulnerable have replaceable parts or coverings.

The main body has replaceable “Skid Plates,” and the outer parallelogram is now two pieces, and both are replaceable. The bushings are contained in those parts too, so if you do wear them out and things get sloppy, just replace those and it should look and feel new.

The pulley cage is now removable without tools. Notice how there’s no bolt on the back of the cage’s pivot?

That’s because it just twists out, with no tools required. This makes swaps quick and easy, and if you’re packing your bike for travel, just rotate it up and out of the way; there’s no need to remove the entire derailleur from the bike.

All three models are completely interchangeable, so if you smash yours and need to replace it, you can use whatever your local shop has on hand.

Since the clutch’s spring is now fully captured on the cage, I asked SRAM how long they thought it’d be before we saw aftermarket options with oversize pulleys and SRAM responded, “Good luck with that.”

It’s not just the integrated clutch spring that makes it harder to imitate. SRAM has already given it a larger 14-tooth lower pulley, but it’s no ordinary pulley. It’s a “Magic Wheel.” Normally, the whole pulley rotates on its bearings like normal, but if something got stuck in its spokes and cage, the outer ring with the narrow-wide teeth can spin independently of the center so that the chain keeps moving and doesn’t jam up and break the derailleur.

Lastly, the cage itself is called “Inline Cage” and is angled slightly so that it works with the parallelogram to keep the lower pulley aimed directly at the chainring as it shifts across the cassette. This, among other refinements to the chainrings and new chains and cassette, all help reduce noise and keep the system running more smoothly.

SRAM Transmission: XO vs. XX vs. XX SL

At launch, there are three levels of Transmission groups: XO, XX, and a new XX SL. Think of them as being for all-mountain/enduro, trail, and XC, respectively. XO has gradually become more of a high-performance, do-it all group, and this new iteration fully commits to aggressive riding.

The key differences in the derailleurs are materials and the amount of finishing work applied to weight-saving efforts.

XO gets the least machining, particularly visible on the Full Mount cage (the part formerly known as the B-knuckle). It gets more robust Skid Plates and a stamped metal pulley cage.

XX gets more machining, slimmer Skid Plates, and a CNCd alloy pulley cage with a slimmer hub on the lower pulley.

XX SL T-Type derailleurs get the most machining, including a bit of material removal on the mounting bolt’s surface. Skid Plates are minimized, and the pulley cage gets a carbon fiber outer plate.

One last thing to note: The clutch’s damper force is stronger on Transmission derailleurs, so it requires more power to shift, making battery life slightly reduced.

SRAM T-Type Cassette

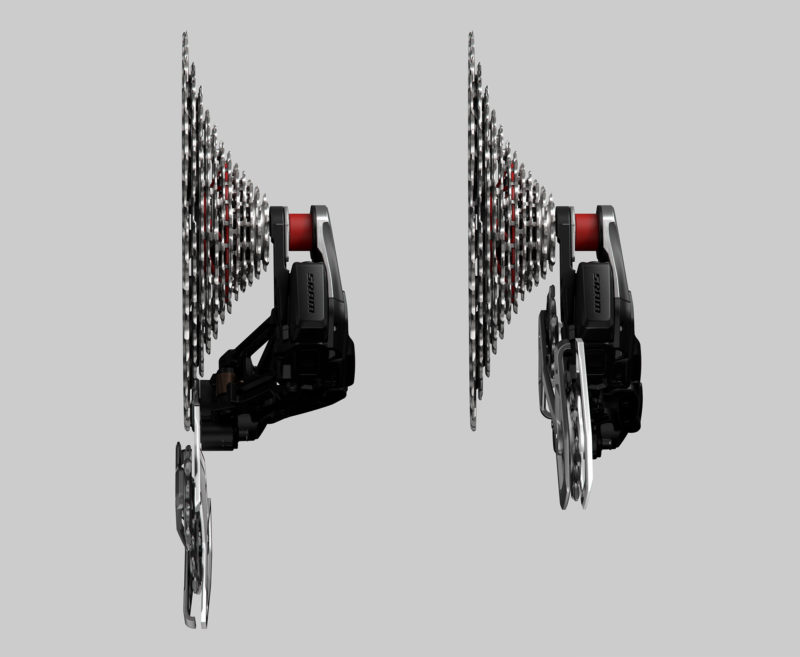

The new T-Type cassettes use subtle narrow-wide tooth profiles on most cogs along with well-defined ramps and shaping. The goal is to allow you to shift at any time, under any load, and have it execute perfectly and silently.

There’s only one cog with an odd tooth count number, and that’s the “setup” gear indicated by that red plastic insert, which is only there to show you which cog to use during the system’s installation. It’s not a noise damper, support, or anything else.

All the other cogs have even tooth counts and a narrow-wide X-Sync profile. The “wide” teeth aren’t as wide as on the chainrings, and depending on where they sit on the cog, they could have different or no wide shaping. This is to improve chain retention and shifting under load.

The other big factor in shifting improvement is the shift ramp shaping. They’re designed to support the chain and maintain constant contact and engagement even during shifts. They’re also there to ensure proper transfer of the outer plates onto the wide teeth, and vice versa.

If you happen to put the chain on in the wrong “timing” during setup, SRAM says it’ll just skip ahead in your first couple of pedal strokes to get the narrow-wide timing. But once it’s on and rolling, it will shift such that the outer chain plates land on the wide teeth, and vice versa. Combined with the super stiff Full Mount derailleur, you have a system that works together to provide seamless, robust shifting.

This leads to an important point: Transmission shifts slower than Eagle AXS.

Each shift is very intentional. If you tap the shift button several times really quickly, the derailleur will perform one shift at a time, pause for half a second, then execute the next shift. It’s weird, but it works. I’ll have a full ride report soon and cover this in more detail but suffice it to say you can shift at any time and it won’t hesitate, but you can’t just smash through five gears at once either.

Gone is the X-Dome one-piece machined steel cassette body, which was light but also ridiculously expensive.

The new designs mix machined multi-cog parts with separate cogs pinned into place. The XO and XX cassettes have different finishes but are otherwise the same. They both use a machined steel one-piece lower cluster for the first nine cogs. The 10th and 11th cogs are steel and are pinned to an alloy 12th cog, which is then pinned onto the lower cluster to create a one-piece unit.

The XX SL cassette replaces the 10th and 11th cog with alloy to save weight but uses the same machined-plus-pinned construction.

Can I Use the Transmission Cassette Without the Direct Mount Derailleur?

Transmission runs on a 55mm chainline (standard is 52 mm).

Since there’s no derailleur hanger anymore, the XD driver body’s end cap sits directly against the derailleur body, not a dropout, hence the “Full Mount” name.

This lets SRAM move the cassette outboard 2.5 mm to make up for that, so the relationship between the chain and cassette is (basically) the same as before.

This actually gives bike brands more chainring and tire clearance at the chainstay, but it means you’ll probably need to add more spacers on the drive side between the BB and crankset. It still uses DUB spindles and there’s nothing new about the bottom brackets, so any DUB BB will work.

Because of all this, the new cassette is incompatible with older drivetrains, mainly because it moves outboard and could (likely would) rub against the hanger, UDH, or dropout.

What About Super Boost Bikes?

At launch, there’s no 56.5mm SuperBoost crankset spindle. But you could add a T-Type chainring to compatible SRAM cranks on a Super Boost bike because it’s not the cranks themselves that are T-Type, it’s the chainring.

SRAM T-Type Flat Top MTB Chains

The new Flattop mountain chains are SRAM’s strongest chains ever. XO has standard pins and plates, XX gets hollow pins, and XX SL gets hollow pins and cut-outs on the outer plates. XX and XX SL get their Hard Chrome finish for improved durability.

Yes, they look like Road Flattop chains, but no, you should not use a Road Flattop chain on this MTB group. For mullet gravel builds, use the MTB Flattop chain.

They come with 126 links and use a new T-Type Flattop Quick Link that, SRAM says, is definitely not meant to be reused.

SRAM told us that, technically, you’re not supposed to reuse any quick links, but let’s be real, most of us do. But SRAM likes to remind you again that you shouldn’t do that. The actual press-fit design aspect hasn’t changed, but it says it weakens a little when you release it, and you should just replace it with a new one. Also, the original Eagle 12-speed chain quicklinks shouldn’t be used on the Flattop chains.

SRAM Transmission Cranksets, Power Meters, and Chainrings

Each group gets its own crankset. Carbon cranks are effectively the same as before. XX is basically the prior XO with a foam core. XX SL is basically the prior XX with a hollow carbon arm.

Remember the AutoDesk story? Turns out that’s exactly how it designed the new alloy XO crankset. After inputting the criteria, AI spit out a few design options. SRAM sorted through those to find the design it liked and then optimized that for actual riding conditions.

The raised portion gets polished exactly where someone’s heel would rub it, keeping it looking fresh. More importantly, it’s very strong and very stiff, keeping with the trail-to-enduro vibe the XO group is aimed at.

All three come in 165/170/175mm arm lengths.

The new T-Type chainring tooth profiles are optimized for the new Flattop chain, so they are slightly different than non-T-Type chainrings. And they now use the 8-bolt direct-mount interface, not the 3-bolt. Chainring size options are:

- XO: 30/32/34

- XX: 30/32/34/36

- XX SL: 32/34/36/38

They also have T-Type chainrings for Bosch, Brose, and Shimano Steps e-bike systems, as well as their own T-Type e-bike cranksets.

Both XO and XX cranksets come with integrated bash guards on the chainrings. They’re removable and positioned only where you need them. They’re model-specific and chainring size-specific.

The XO bashguards have backing plates, but the XX ones save a bit of weight by bolting directly together. Fortunately, the heavier stamped XO chainring and the more heavily machined XX version (and XX SL) are all interchangeable between any of the cranksets.

SRAM will have two power meter options for Transmission. Not shown, the XO/XX cranksets both have left-side spindle-based power meters available, either as a complete crankset or as a left-only upgrade for an existing group.

The XX SL group gets an integrated Quarq power meter spider with new thread-on chainrings. It’s a clever design that allows for quick chainring swaps (a special tool recommended and available, but … you can probably do it with a chain whip).

Once twisted on, a set screw prevents accidental loosening. It uses a replaceable CR2032 battery good for 200 hours of run time and connects via ANT+ and Low Energy Bluetooth. Standard direct-mount 1x chainrings will also be available, either sold separately or as part of the crankset.

All three of the power meters will connect with its Flight Attendant suspension too, so there’s no need to add an additional cadence sensor to use its auto-adjusting suspension.

SRAM AXS Pod Controllers

The only part of the new groups that’s cross-compatible are the new pod shifters — meaning, you can run these with Eagle AXS and you can run AXS paddle shifters (Road, MTB, Blips) with the new Transmission derailleurs. Anything that could be controlled with AXS remotes (Reverb, etc.) will work with these too. They come in two versions — standard and deluxe — and with two different mounts.

The direct-mount clamps directly to your bar, with a slim band that should fit into any cockpit setup. The Matchmaker mount attaches to SRAM’s brake lever clamps and provides a wider range of lateral adjustment than the two-position system of the originals.

The standard Pod has fixed concave button pads. The Deluxe version has removable buttons with both concave and convex pads; mix or match to create the exact tactile experience you want. You can also flip them left to right, rotate them independently of the mount’s rotation, and assign the buttons to do whatever you want via the AXS app.

The Pods’ pairing button does still work as a trim button, which is great for setting up AXS groups, but SRAM says it’s unlikely you’ll ever need to use it for Transmission groups.

SRAM Transmission Actual Weights

Remember the three reasons SRAM gave for making this group? Weight wasn’t one of them. That said, it’s all respectably lightweight.

All cranks measured are 175mm lengths. The XO crankset comes in at 667g plus 81g for bash guards for 748g complete.

The XX crankset is 542g with 53g bash guards, 595g complete.

The XX SL crankset with power meter and 34-tooth chainring is 550g.

I didn’t have a standard chainring to weigh, but at just an 8g weight gain to add a power meter, there’s basically no penalty beyond cost.

T-type derailleur range from 449g for XO to 419g for XX SL. Batteries add 25g.

XX and XO cassettes are nearly identical at 382g and 381g. Somehow, I didn’t weigh the SL cassette but will be adding this later once I do. Claimed weight is 345g for XX SL cassette, and claimed weight for XO/XX is 380g.

Chain weights are 282 g (XO), 274 g (XX) and 264 g (XX SL).

Shifter Pods are 35g each. MMX mount with brake lever clamp is 35g, and the standalone mount is 12g (47-35g).

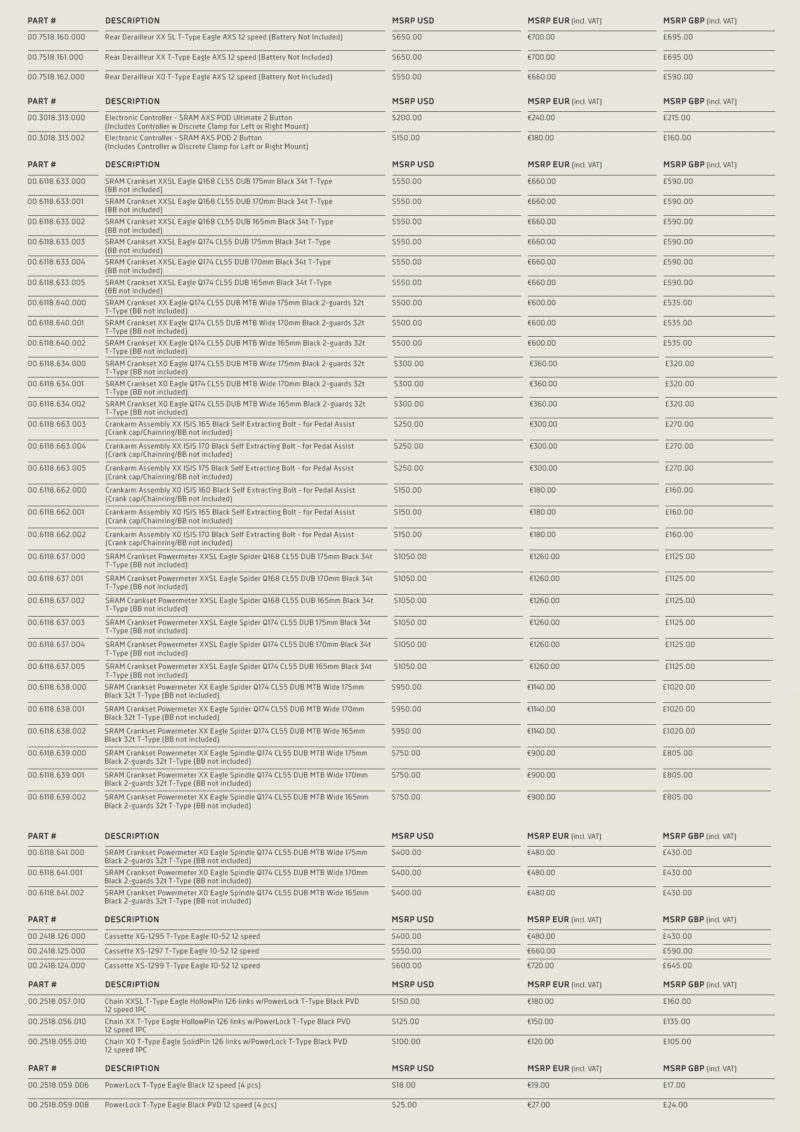

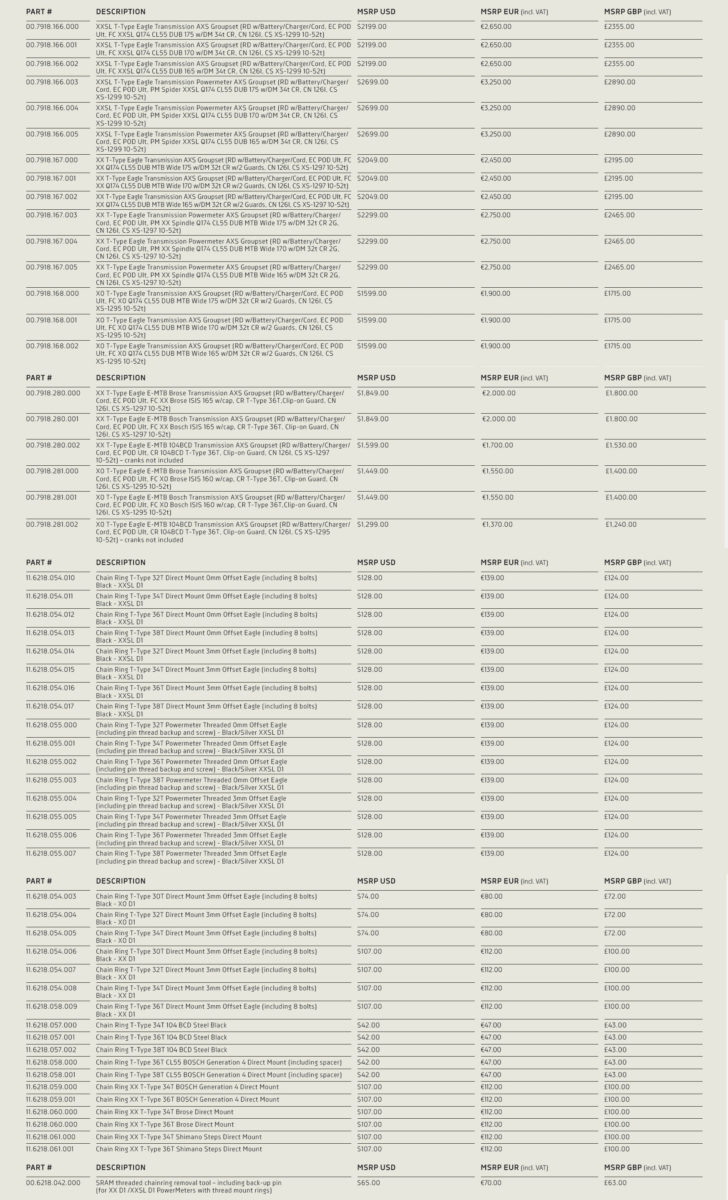

SRAM Transmission Pricing & Availability

Prices above are for individual standard components, and below are for complete groups and chainrings.

All SRAM Transmission parts start shipping at launch in March 2023. Expect immediate availability on complete bikes and separate aftermarket availability very soon. Basically, if you have a bike with a UDH hanger on it, it’s compatible.