We know, there’s no such thing as a stupid question. But there are some questions you might not want to ask your local shop or riding buddies. AASQ is our weekly series where we get to the bottom of your questions – serious or otherwise. Hit the link at the bottom of the post to submit your own question.

Welcome back to the Bikerumor Ask A Stupid Question series. This week we’re taking a look at the environmental impact of drivetrain lubrication, challenging the big-names and the small producers alike on how they’re improving their chain lube formulas to make them less toxic and more environmentally friendly overall. Joining us this week are:

-

- Borut Fonda, Scientist at absoluteBLACK

- Josh Poertner, CEO of SILCA

- Bryn Morgan, Product & Design Director, and co-founder of Peaty’s

- Paul Sollenberger, Product Manager at CeramicSpeed

- Jay Seiter, Product Management and Engineering at Pedro’s

- R&D Director at MUC-OFF

What are bike chain lube manufacturers doing to make their products less toxic and more environmentally friendly? I’m aware there are a number of brands out there who make the “eco-friendliness” of their lube a major selling point, but how are the bigger brands looking to improve their existing products to prevent them from harming the environment?

SILCA: For the first 9 months after I bought SILCA, I ran the company out of my living room, including all of the small part assembly and packaging. As I had my whole family including my kids helping with the work, it became instantly obvious that we had to use the safest products possible. So, really from day one, we’ve only used lubricants, greases, and assembly compounds that are NSF approved as safe for food contact in all SILCA products.

When we came to develop our line of lubricants, it was only natural to work with the same food-safe suppliers, as well as tapping into technologies evolving within auto racing where we had access to some research and technology that was done in Europe as part of a project to ‘green’ engine lubricants used in F1 racing. The vision was not to develop just an environmentally friendly lube; those have been around forever and are generally regarded as being pretty bad. What we were after was developing the world’s best chain lube in terms of friction and wear using only environmentally sound base stocks and additives, and this F1 tech, gave us a pathway to do so in both dry and wet lubricants.

What we discovered was a lubricant technology vastly superior to PTFE and other PFAS related chemicals which was also deemed completely safe for human contact, water contact, and safe for aquatic life. If you look at independent testing, like that from Zero Friction Cycling you see that our technologies are number 1 or number 2 in every category when it comes to preventing chain wear, and we are also one of the most commonly referenced lubricants by our competitors when it comes to efficiency testing, so we can say without exaggeration that we have developed some of the best lubricant technologies currently on the market, which also happen to be completely environmentally friendly.

While we hope to build a strong business position in cycling lubricants, we also seek to create meaningful change in this industry, so in October 2021, we put out a statement to the industry disclosing all the ingredients and technologies used in our lubricants that also asked the industry to stop using PFAS ‘forever chemicals’ as well as toxic and flammable VOCs in cycling lubricants. We seek to educate dealers and consumers that some of the most toxic and dangerous lubricants on the market are also the slowest and most drivetrain damaging products (which is an additional environmental impact), but good marketing and low retail price points keep these products on shelves.

My hope is that by having these discussions and being as open and transparent as possible, we can inspire other manufacturers to move away from these dangerous and toxic chemicals and toward safer (and better performing) ingredients. Sadly, the biggest hurdle here is likely cost; it costs just pennies to put PTFE or similar PFAS particles into a toxic VOC like Heptane, in many cases these lubes are only 5-10% lubricant in a volatile carrier and therefore are extremely cheap to produce and can be sold at high margins at very low prices.

This is just not the case with some of these modern high-tech, environmentally-safe base oils, and additives, which is why it is so important to educate consumers and retailers to not just the environmental benefits, but also the drivetrain life improvements which can make these superior lubricating technologies much less expensive over the long run if you cost things out with a ‘total cost of ownership’ type model. While the superior lubricant may be $10-15 more expensive upfront, it may double or triple the life of your $60 chain and in turn double or triple the life of your $300 cassette, which not only saves money but has its own environmental story by reducing the need to manufacture replacement parts, dispose of the worn-out parts, etc.

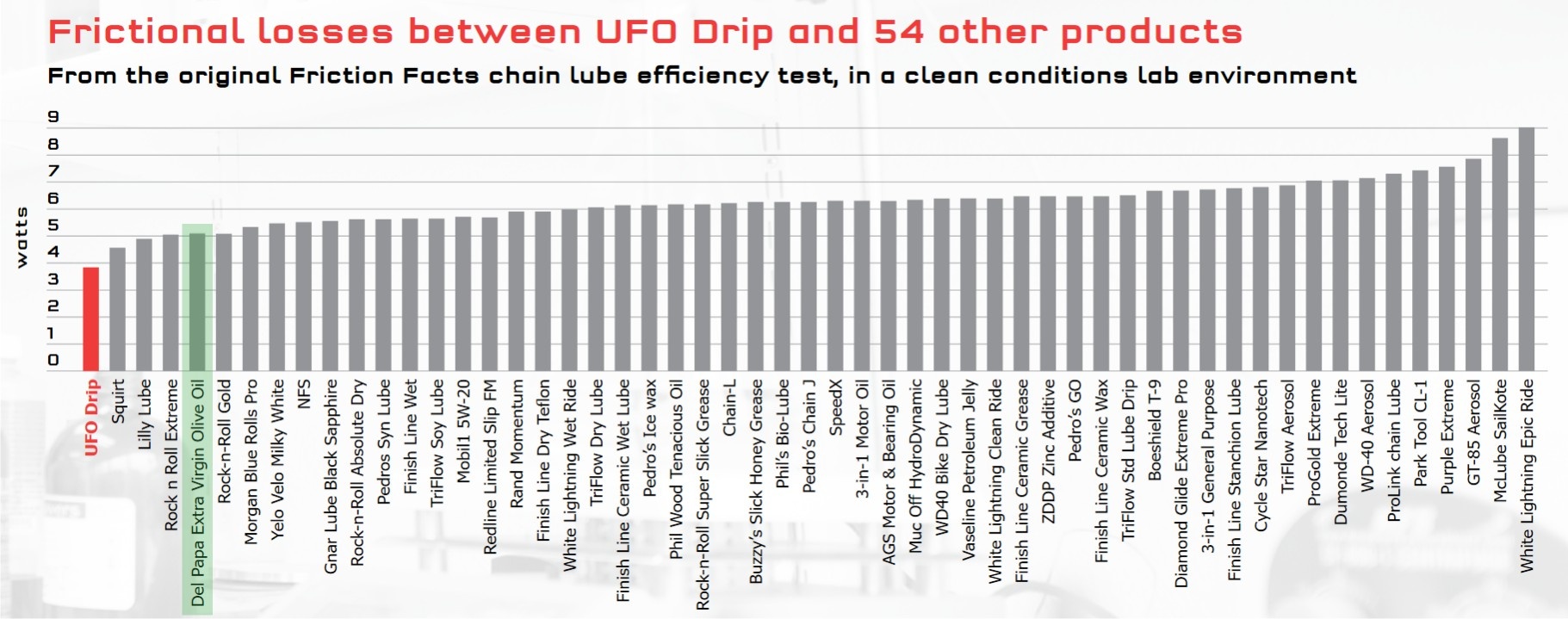

Ceramic Speed: CeramicSpeed is a proudly Danish company, with environmentally conscious choices rooted as cultural norms and present within all levels of the company. When CeramicSpeed first approached the chain lubrication market in 2016-2017, we were laser-focused on creating the most efficient chain product possible, bar-none. While we achieved this target with our first UFO Drip formula, we immediately challenged ourselves to achieve an eco-friendly formula that still achieved our efficiency targets. From bottling and shipping to storage and user-friendliness, we valued the positive impact an eco-friendly, non-toxic, and biodegradable formula would deliver.

During this period, we also addressed our chain optimization operations, and discontinued the use of hydrocarbon solvents for chain cleaning, introducing our own in-house chain cleaner that was non-toxic and eco-friendly. This later was released as a consumer product, known as our UFO Clean Drivetrain. Today, non-toxic and biodegradable are key criteria for our chain products and cleaners, both for our own production uses, as well as consumer products.

We believe that it takes solidarity to implement lasting positive changes, and we approach our entire product range with longevity as an important piece of our product value proposition. With serviceable bearings, rather than disposable parts, and lifetime warranty support on our coated bearings, our aim is to offer products that enhance your riding while also reducing the need to replace more parts due to wear.

absoluteBLACK: There are a few factors that should be considered regarding the impact of lube on the environment.

The main ingredients of the GRAPHENlube are water, wax, and a small amount of graphene which binds to the wax. There is no safer carrier in the chain lubricant than water and no better “chain link separator” than wax. Since wax is not really a “lubricant” on its own, we use graphene to achieve the desired lubricity. If you care about the environment, you should use lubricants that contain water as a carrier.

We also don’t offer a plethora of lube types for “different conditions” meaning that we minimize the generated amount of plastic waste. We have only two types, and both are based on wax that is nontoxic. We don’t use Teflon powder nor volatile solvents commonly seen in “dry lubes” as this is an environmentally unfriendly option (in our opinion).

Toxicity is one aspect, but the quantity of lube you are expelling into the environment during cycling is equally important. The more lube you need to use the more you pollute and more needs to be produced increasing plastic waste. We developed the longest-lasting lube on the market, meaning that you use very little for very long. That alone minimizes the waste and the ecological impact. One bottle can last up to 16,000 km (9950 miles) of use with very low friction, which also means that you are greatly extending the life of your drivetrain components (like chain and cassette), minimizing the number of parts that end up in a landfill over time.

A chain lubricated with GRAPHENlube does not need to be repeatedly cleaned with any sort of chemical degreasers. All you need to do to get a clean drivetrain is a clean cloth and boiling/hot water, which melts the wax.

Minimizing toxicity alone is important. However, what really matters is the full picture. What evaporates from the lube during the application, how much lube you need to use per km, how many plastic bottles this generates, what chemicals you will have to use to clean dirty lube off the chain before reapplication, how easy it is for the lube to drip into the environment, and lastly, how often you will need to replace your drivetrain components (generating more product waste and packaging).

Peaty’s: The balance – as ever – is between performance/durability and eco-friendliness.

A good chain lube will keep your drivetrain running smooth and clean for longer periods of time without gunking up into an immovable paste. Wet-specific lubes also need, more than any other lube, to stop flash rust (after water is left on a chain for long periods of time) and prevent your chain from premature death.

Ultimate eco-friendly/plant-based/renewable oil alternatives do not provide this level of performance without the addition of further things like water-proofing agents, high-pressure additives, and rust inhibitors – all of which need manufacturing and transporting from all over the world, so are not as eco-friendly. It’s of course possible to run a chain on olive oil, but the consumer would need to apply the lube far more frequently and manually, and thoroughly dry off their chain after every wash or ride to prevent rust.

Take our LinkLube Dry for example. It’s the most eco lube in our range, made up of a water-based wax emulsion that uses completely natural and renewable waxes. The only human-made additive in there is a fungal inhibitor, but this is only to stop bacteria growing in there while sitting in storage (oxygen + water + food (wax) + warm environment = fungal growth).

This lube is totally awesome in dry, dusty conditions – doesn’t attract dust and lasts ages – but naturally doesn’t last as long in wet conditions. Now if we sold this as a wet lube we’d probably be scored 2 stars in a magazine review – and people wouldn’t buy it – but it does work, it just requires more frequent application in wet conditions and more hands-on bike care from the consumer.

All of our lubes (even our wet lube) are really easy to wash off which again is really important. If a lube has crazy waterproofing additives to make it last forever in wet conditions then it’s very likely to gunk up and requires more savage, non-eco-friendly degreasers to remove it… A super eco/non-toxic lube that needs a super toxic degreaser to remove would be a bit daft.

For us, more than saving a watt or two at the expense of the environment, ultimately a chain lube needs to make maintaining your whole drivetrain incredibly easy, and make it last for many miles longer. If you take into account everything that goes into the making of drivetrain components (extraction/processing of raw materials > transport to manufacturer > parts manufacture > packaging > parts shipping > distribution > logistics) then maintaining existing components rather than wearing them out quickly and purchasing again new is ultimately the greater good for the environment… That’s even more important when you take into account the shortage of drivetrain components these days!

Our wet- and dry-specific lubes are completely readily biodegradable whilst providing all of the necessary durability and protection, so we’re doing what we can, but nobody can hide from the fact these products still need manufacturing, packaging, and shipping to reach a consumer.

On the packaging front, we always try to make our bottles transparent, with minimal single-color printing to enable easier recycling once the chain lube has been used up. Did you know most black bottles can’t be recycled?

Both of our LinkLube All-Weather and Premium All-Weather chain lubes could be classed as readily biodegradable by the technical standards however, morally, we wouldn’t want to advertise them like this as there is a small percentage of non-biodegradable ingredients in there. Unfortunately, these ingredients are crucial for the all-weather performance those lubes are loved for (we tried removing them but they just didn’t work as well), but we’re continually searching for alternatives to also make those lubes perform just as well but with 100% readily biodegradable ingredients.

Pedro’s: Pedro’s bike care has led the way since the early 90s with user safety and environmentally-friendly formulas being central to all our offerings. Our biodegradable Oranj Peelz degreaser, first offered in 1994, contains less than 30% solvent content; far less than our “bigger brand” competitors even today who often rely on solvent content as high as 75-95% in their “citrus” degreasers (only 0.1-1% of which is actual citrus solvent).

Not content with that, in 2012 we started working on degreasers that were completely free of chemical solvents. The resulting products, Degreaser 13 and Pig Juice were introduced in 2015. The process was not without challenges. In the chemical world, not all the players play by the standards that we do at Pedro’s.

When we found out a key ingredient could potentially contain trace amounts (contaminants) of a chemical listed on California’s Prop 65 list, we hit the brakes and found a solution we knew would be safe for our customers. It was worth it. Degreaser 13 is an incredible solvent-free advanced-chemistry surfactant degreaser designed for use with water instead of chemical solvents. It is now our highest performing and most versatile degreaser. It is biodegradable, non-hazardous, non-flammable, zero V.O.C., plant-based, and safe to use on any material.

With a higher viscosity and concentrated power, it can be applied very efficiently with almost no dripping/waste, and less is needed. Degreaser 13 is also ideal for use in ultrasonic parts cleaners where it can be diluted with up to 30 parts water. Pig Juice is a low viscosity solvent-free advanced-chemistry surfactant degreaser featuring the same base chemistry found in Degreaser 13. It features less raw power but requires less rinsing and flows nicely into tight spaces. Pig Juice was formulated for use in the Chain Pig chain cleaner which uses mechanical action to reduce how much degreaser is needed to clean a chain. When done regularly, only 1oz of Pig Juice is needed per cleaning. Pig Juice is biodegradable, non-hazardous, non-flammable, zero V.O.C., plant-based, safe to use on any material, fragrance-free, and dye-free.

For cleaners, our Bike Lust polish, the original bike polish, is fully biodegradable and non-toxic and has been keeping bikes clean, protected, and looking like new since the early 90s. It is a staple in bike shops used daily for keeping showroom and customer bikes looking their best. Bike Lust’s slippery coating helps to repel dirt and grime while you ride which makes future cleaning quicker and easier. It is also fantastic for water-less light-duty cleaning.

Bike Lust’s biodegradable formula cleans, polishes, and protects in one step, going on wet, quickly cleaning light dirt and grime as it polishes, and then dries to a beautiful protective coating. More recently introduced in 2007, and further improved in 2015, our Green Fizz bike wash safely, naturally, & effectively removes tough dirt & grime from the whole bike. The pre-activated formula uses advanced plant-derived surfactants and incredible foaming action to reach surfaces and loosen dirt allowing it to be easily wiped or rinsed away leaving your bike looking like new.

Green Fizz is free of harsh chemicals, gentle enough to use on any material, biodegradable, phosphate-free, solvent-free, plant-derived, and zero-VOC. We also offer Green Fizz as a 16X concentrate. One bottle of 16X Concentrate will make SIXTEEN 16oz bottles of Green Fizz bike wash! So what is the big deal? It’s all about reusing that perfectly good spray bottle you already own, reducing energy use, and saving money! Green Fizz 16X Concentrate is incredible value and allows you to custom-tune cleaning power; boost strength for tough jobs or dilute further for even more economy.

In terms of lubes, Pedro’s started pushing the needle in 2007 and 2008 introducing fully non-toxic and biodegradable Chain Lube, Go!, and Ice Wax 2.0 lubes which were way ahead of the curve. Fast forward to 2015 and after many years working on our next generation of lubes, we launched Enduro, X Dry, and Slick Wax. These lubes feature our CleanTech Chemistry which is a proprietary approach to chain lubrication chemistry developed by Pedro’s to achieve new standards of performance using ingredients that are safe for mechanics and riders.

Chain lubes commonly feature toxic ingredients that are unsafe for the user and harm the environment. With CleanTech Chemistry, there are no compromises. CleanTech Chemistry lubes share a similar base chemistry but each employs a unique lubricant package designed to optimize the chain surface coating characteristics and maximize performance for the intended riding conditions while keeping the drivetrain exceptionally clean. These lubes use a plant-based ethanol carrier to deliver the lube package where it is needed and are biodegradable, use safe non-toxic ingredients including only plant-based oils and waxes, and importantly still offer incredible race-proven performance.

Looking to the future, we continue much as we did back in the 90s with a focus on user safety and environmentally-friendly formulas. We will continue to look for ways to make our formulas even safer, continue to reduce how much of our product is needed to get the job done and to find new ways to reduce packaging.

How could we make our formulas ever safer? As safe as our current formulas are, we continue to strive to do even better while always balancing these goals with performance. What good is a safe product if it doesn’t work? For instance, some of the ingredients in Degreaser 13 can cause irritation to skin and eyes as is cautioned about on the label. You’ll find the same cautions on safe eco-friendly laundry detergent. Still, we would love to advance our degreasing chemistry to the point where these cautions are no longer needed but so far the balance with performance isn’t there yet.

MUC-OFF: By far and away the biggest change for us in terms of making our lubes less toxic and more environmentally friendly has been the removal of PTFEs from our entire lube range (and cleaning/protectant ranges). PTFEs can cause serious harm to wildlife when they drain into water sources, so developing alternatives to this was a big focus for us.

In terms of wider focus on environmental considerations where our lube development is concerned, our joint research project with the Laboratory of the Government Chemist (LGC) and National Physical Laboratory (NPL) represents an interesting case in point. While the time constraints of a three-month collaboration confined us to the performance aspects of lubricant development, many of the learnings that emerged from the laboratories of LGC and NPL have advanced our understanding of readily biodegradable formulas.

Our Project Landa Story:

Back in 2020 we developed an ultra-low-friction lubricant for Mikel Landa; although the sole priority was to create the most efficient lubricant possible (one with the lowest possible coefficient of friction) rather than to formulate a high-performance solution from biodegradable components, the story led to some very interesting findings, which would change the shape of our lube development process thereafter.

Two strategic considerations underpin the success of the Project Landa lubricant as a biodegradable formula. The first was to create the lubricant from scratch and to benchmark each individual component; a huge undertaking that led to more than 200 hours of screening, but which provided ultimate control over its chemical composition. The second was to follow a conventional formulation process, blending base oils and additives, rather than using nanoparticles.

While motivated by time constraints (creating a formula in which the behaviour of certain nanoparticles is stabilized can be very time-consuming), it allowed us to consider a range of base oils and additives, including those classed as biodegradable, that formed part of the final formula.

The base oil used in the Project Landa lubricant is an ester, rather than a mineral oil or even a Group Five synthetic oil (polyalphaolefin), both comprised of hydrocarbon chains, whether by refinement or synthesis. While esters are also synthesized, the presence of oxygen in their branched structure, in addition to hydrogen and carbon, allows them to degrade by natural absorption of the oxygen molecules.

Esters offer the advantage of high viscosity too, allowing the Project Landa lubricant to reduce component wear, as well as to provide supreme efficiency thanks to its ultra-low-friction properties. Both qualities result from the absorption of oxygen molecules on the lubricant’s surface. While oxidization can compromise an ester’s stability, typically this occurs only at very high temperatures, such as those inside a car engine, making it a remote contingency for a cycling time-trial held in September at a ski station in northern France.

The formula’s success can be measured in large part by Landa’s performance on stage 20. While the Basque rider is regarded as one of the world’s best climbers, he is not considered a time-trial specialist. Even so, his performance against the clock, and notably on the brutal finishing ramp to La Planche des Belles Filles, was enough to move him up the final standings. He rolled into Paris the following day in fourth place overall to claim his joint highest finish in cycling’s greatest race. More details on this and much more can be found on our Performance Hub.

Ludicrous AF:

We have carried this experience through to our latest lubricant invention: Ludicrous AF. Being readily biodegradable was once again at the top of the list of requirements. Dubbed ‘The World’s Fastest Race Lube’ Ludicrous AF takes drivetrain performance to a whole new level. It took our Research and Development Team over three years to create the one-of-a-kind lubricant that was developed in secret alongside pro-cycling powerhouses INEOS Grenadiers and EF Education-NIPPO.

The lube was perfected throughout the 2020 Grand Tour season, with multiple podiums and an overall win at the Giro d’Italia 2020 and 2021 to cement it as the lube to beat for any brand. While it is the fastest lube around, that is not all it offers. Crucially, the formula is non-toxic, offering piece of mind for any rider using it. In wet conditions or when a bike is being cleaned, naturally, lube will be washed away – thanks to its readily biodegradable ingredients, this can happen without impacting the environment.

Ludicrous AF will also prolong the life of a rider’s chain and even bring it back to life. The lubricant continues to improve with chain run-in due to continued surface improvement at a molecular level, so riders save on environmental wastage by using their existing chain again and again, whilst maintaining the same incredible level of performance.

Beyond Lube:

In 2020, we launched Project Green, an ambitious, wide-ranging, and ongoing initiative led by a bold commitment to eliminate more than 200 tonnes of plastic usage by 2023 – A target that we’re on track to achieving, with the current total sitting at well over 100 tonnes so far.

Our mission has always been continuous improvement for everything we create, we love the planet we ride on and are driven to protect it for futures riders! We’ve always believed in making our products as sustainable and kind to the planet as possible with an ongoing commitment to always improve. We created Project Green as a focus which will never be finished and a commitment to deliver a multitude of improvements across our business. A simple focus to protect the playground we ride in.

Got a question of your own? Click here to use the Ask A Stupid Question form to submit questions on any cycling-related topic of your choice, and we’ll get the experts to answer them for you!